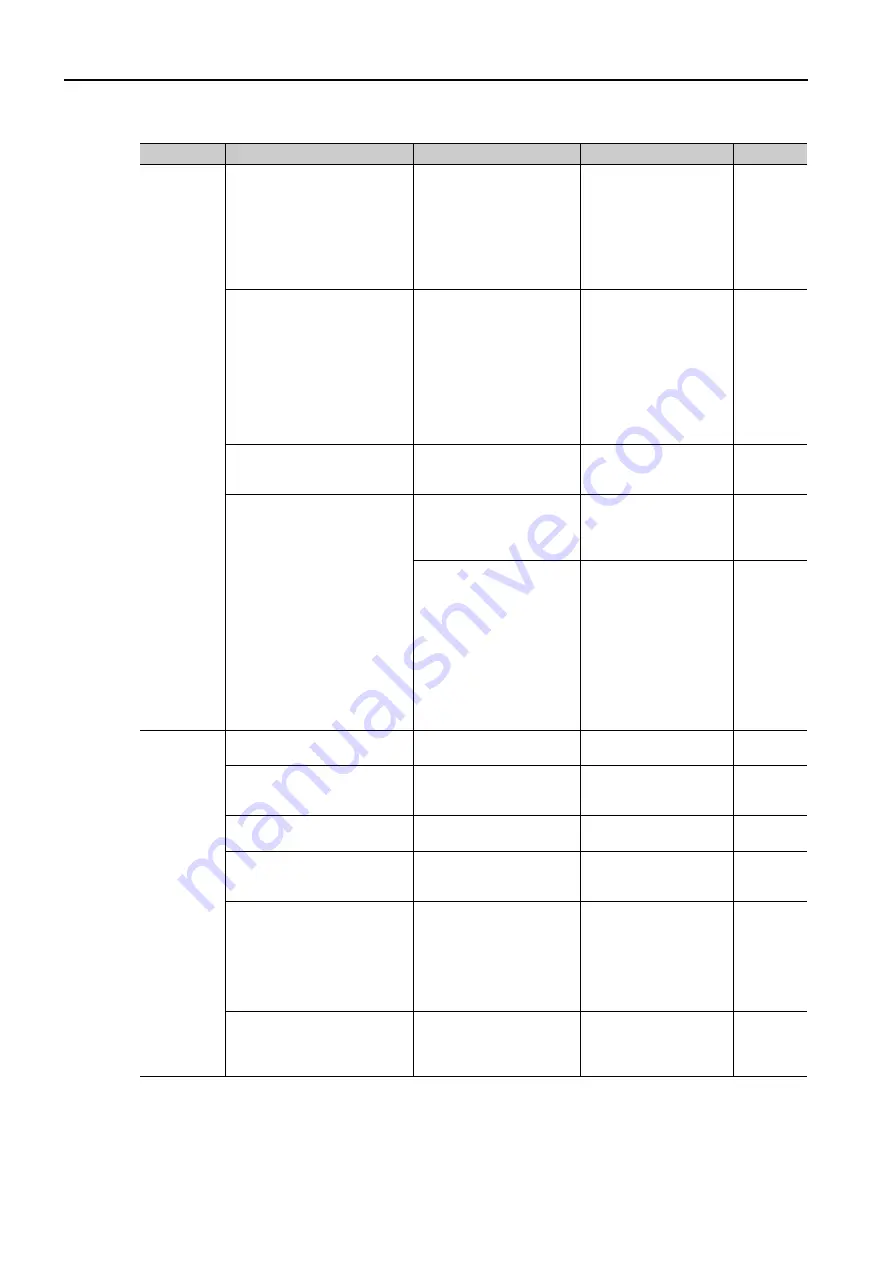

15.4 Troubleshooting Based on the Operation and Conditions of the Servomotor

15-52

Servomotor

Does Not

Start

The safety input signals

(/HWBB1 or /HWBB2) were

not turned ON.

Check the /HWBB1 and

/HWBB2 input signals.

Turn ON the /HWBB1

and /HWBB2 input sig-

nals. If you are not

using the safety func-

tion, connect the Safety

Jumper Connector

(provided as an acces-

sory) to CN8.

The FSTP (Forced Stop

Input) signal is still OFF.

Check the FSTP signal.

•

Turn ON the FSTP

signal.

•

If you will not use the

function to force the

motor to stop, set

Pn516 (2516 hex) =

n.

X (FSTP

(Forced Stop Input)

Signal Allocation) to

disable the signal.

A failure occurred in the SER-

VOPACK.

–

Turn OFF the Servo

System. Replace the

SERVOPACK.

−

The polarity detection was

not executed.

Check the setting of

Pn080 (2080 hex)

=n.

X (Polarity Sen-

sor Selection).

Correct the parameter

setting.

Check the inputs to the

Servo ON command

(Enable Operation com-

mand).

•

If you are using an

incremental linear

encoder, send the

Servo ON command

(Enable Operation

command) from the

host controller.

•

If you are using an

absolute linear

encoder, execute

polarity detection.

Servomotor

Moves

Instanta-

neously,

and Then

Stops

There is a mistake in the Ser-

vomotor wiring.

Turn OFF the Servo Sys-

tem. Check the wiring.

Wire the Servomotor

correctly.

−

There is a mistake in the wir-

ing of the encoder or Serial

Converter Unit.

Turn OFF the Servo Sys-

tem. Check the wiring.

Wire the Serial Con-

verter Unit correctly.

−

There is a mistake in the lin-

ear encoder wiring.

Turn OFF the Servo Sys-

tem. Check the wiring.

Wire the cable cor-

rectly.

−

The setting of Pn282 (2282

hex) (Linear Encoder Pitch) is

not correct.

Check the setting of

Pn282 (2282 hex).

Correct the setting of

Pn282 (2282 hex).

The count-up direction of the

linear encoder does not

match the forward direction

of the Moving Coil in the

motor.

Check the directions.

Change the setting of

Pn080 (2080 hex) =

n.

X

(Motor Phase

Selection). Match the

linear encoder direc-

tion and motor direc-

tion.

Polarity detection was not

performed correctly.

Check to see if electrical

angle 2 (electrical angle

from polarity origin) at any

position is between

±

10

°

.

Correct the settings for

the polarity detection-

related parameters.

−

Continued on next page.

Continued from previous page.

Problem

Possible Cause

Confirmation

Correction

Reference