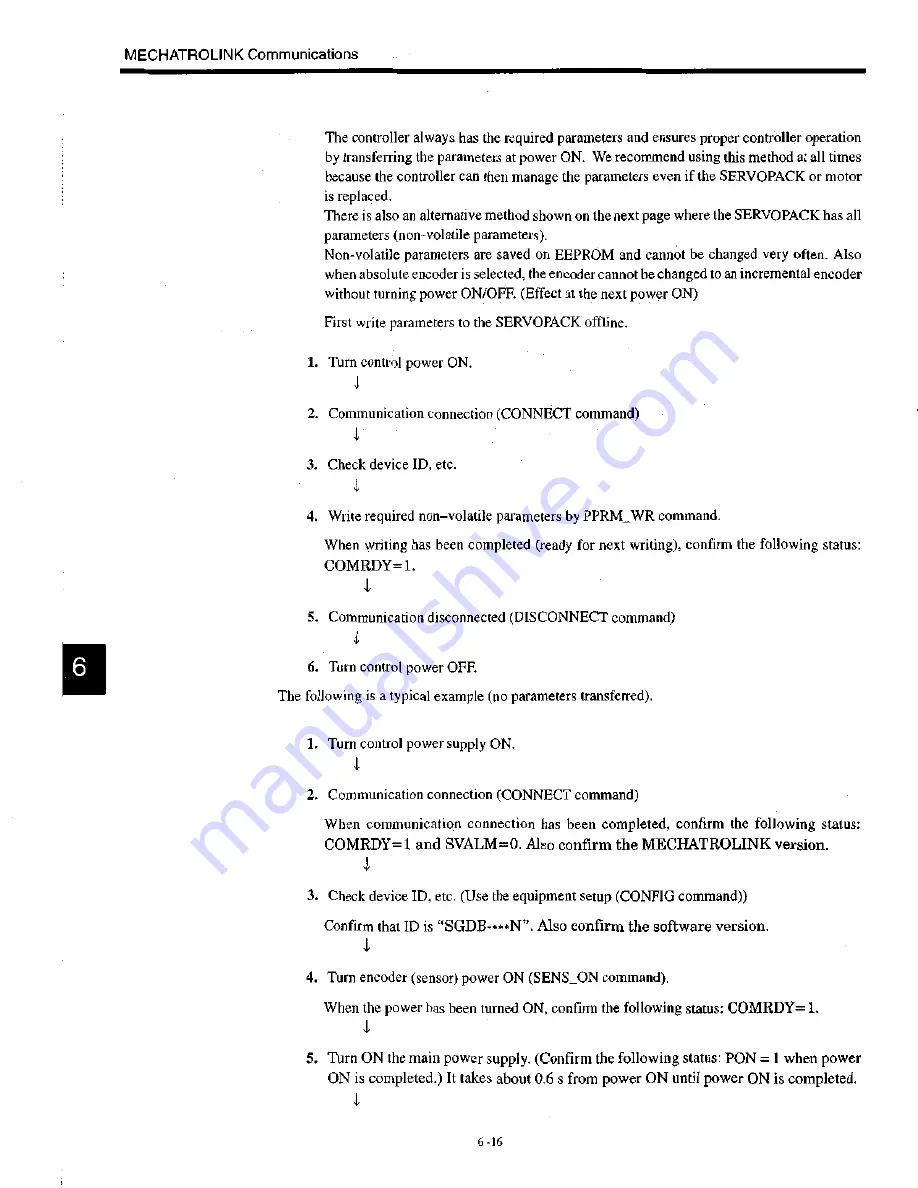

MECHATROLINK Communications

The controller always has the required parameters and ensures proper controller operation

by transferring the parameters at power ON. We recommend using this method at all times

because the controller can then manage the parameters even if the SERVOPACK or motor

is replaced.

There is also an alternative method shown on the next page where the SERVOPACK has all

parameters (non-volatile parameters).

Non-volatile parameters are saved on EEPROM and cannot be changed very often. Also

when absolute encoder is selected, the encoder cannot be changed to an incremental encoder

without turning power ON/OFF. (Effect at the next power ON)

First write parameters to the SERVOPACK offline.

1.

Turn control power ON.

2. Communication connection (CONNECT command)

3. Check device ID, etc.

4.

Write required non—volatile parameters by PPRM_WR command.

When writing has been completed (ready for next writing), confirm the following status:

COMRDY = 1.

5. Communication disconnected (DISCONNECT command)

6. Turn control power OFF.

The following is a typical example (no parameters transferred).

1.

Turn control power supply ON.

2. Communication connection (CONNECT command)

When communication connection has been completed, confirm the following status:

COMRDY= 1 and SVALM=O. Also confirm the M E C H AT R O L I N K version.

3. Check device ID, etc. (Use the equipment setup (CONFIG command))

Confirm that ID is "SGDB-***N". Also confirm the software version.

4. Turn encoder (sensor) power ON (SENS_ON command).

When the power has been turned ON, confirm the following status: COMRDY=1.

1

5. Tu r n ON the main power supply. (Confirm the following status: PON = 1 when power

ON is completed.) It takes about 0.6 s from power ON until power ON is completed.

6 -16