7.5 Procedure for Transferring User Constants

Group

SERVOPACK

Servomotor

Servomotor No.

(Cn-0037 Setting)

05

SGDB-05AN

SGMG-03ADB

ABH

SGMG-05ADA

8EH

SGMP-04A

7AH

SGM-04A

6AH

10

SGDB-10AN

SGMG-06ADB

ACH

SGMG-09ADA

8FH

SGMG-09ADB

ADH

SGMS-10ADA

A3H

SGMP-08A

7FH

SGM-08A

6BH

15

SGDB-15AN

SGMG-13ADA

9011

SGMG-12ADB

AFH

SGMS-15ADA

A4H

SGMP-15A

80H

20

SGDB-20AN

SGMG-20ADA

91H

SGMG-20ADB

AFH

SGMS-20ADA

A5H

30

SGDB-30AN

SGMG-30ADA

92H

SGMG-30ADB

BOH

SGMS-30ADA

A6H

SGMS-22ADA

9BH

50

SGDB-50AN

SGMG-44ADA

93H

SGMG-44ADB

B1H

SGMS-40ADA

A7H

SGMD-32ADA

9CH

SGMS-50ADA

A8H

SGMD-40ADA

9DH

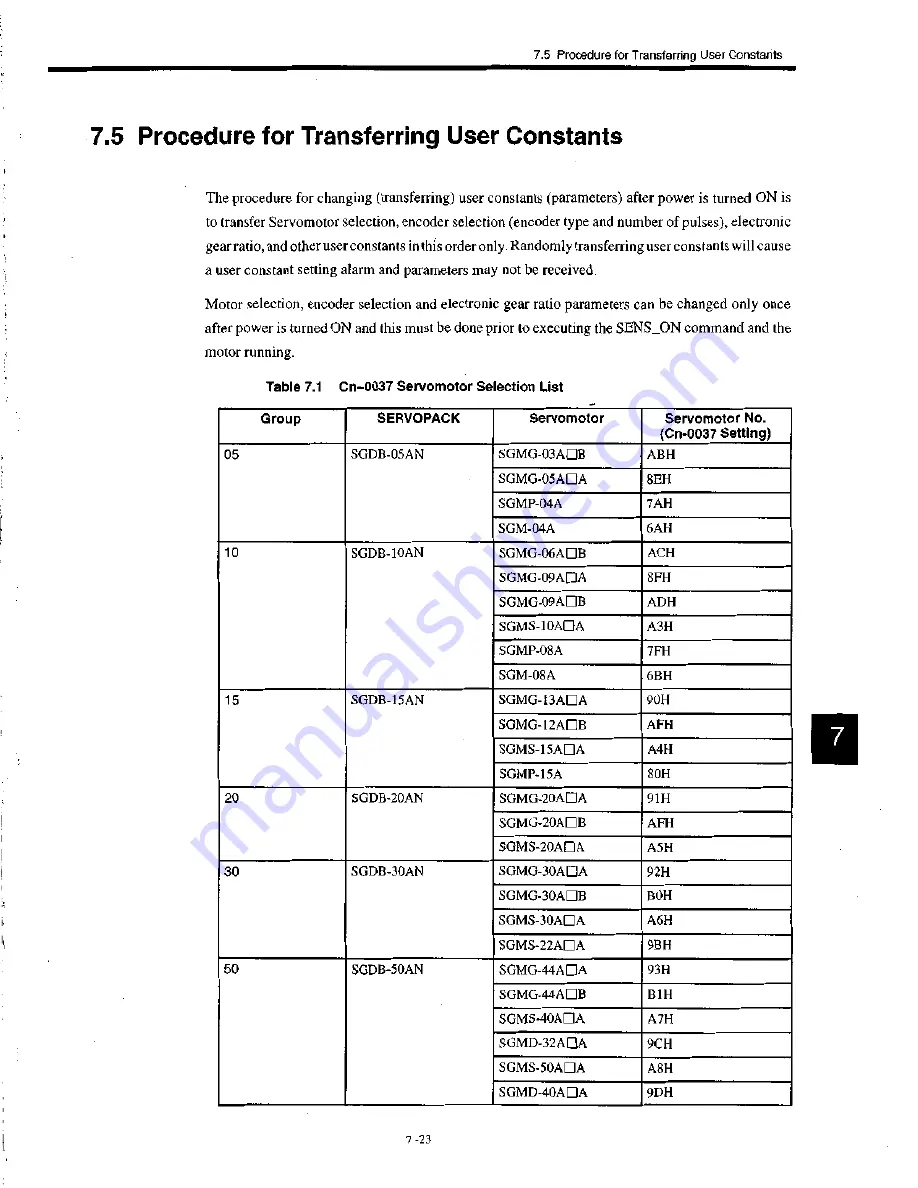

7.5 Procedure for Transferring User Constants

The procedure for changing (transferring) user constants (parameters) after power is turned ON is

to transfer Servomotor selection, encoder selection (encoder type and number of pulses), electronic

gear ratio, and other user constants in this order only. Randomly transferring user constants will cause

a user constant setting alarm and parameters may not be received.

Motor selection, encoder selection and electronic gear ratio parameters can be changed only once

after power is turned ON and this must be done prior to executing the SENS_ON command and the

motor running.

Table 7.1 C n - 0 0 3 7 Servomotor Selection List

7 -23