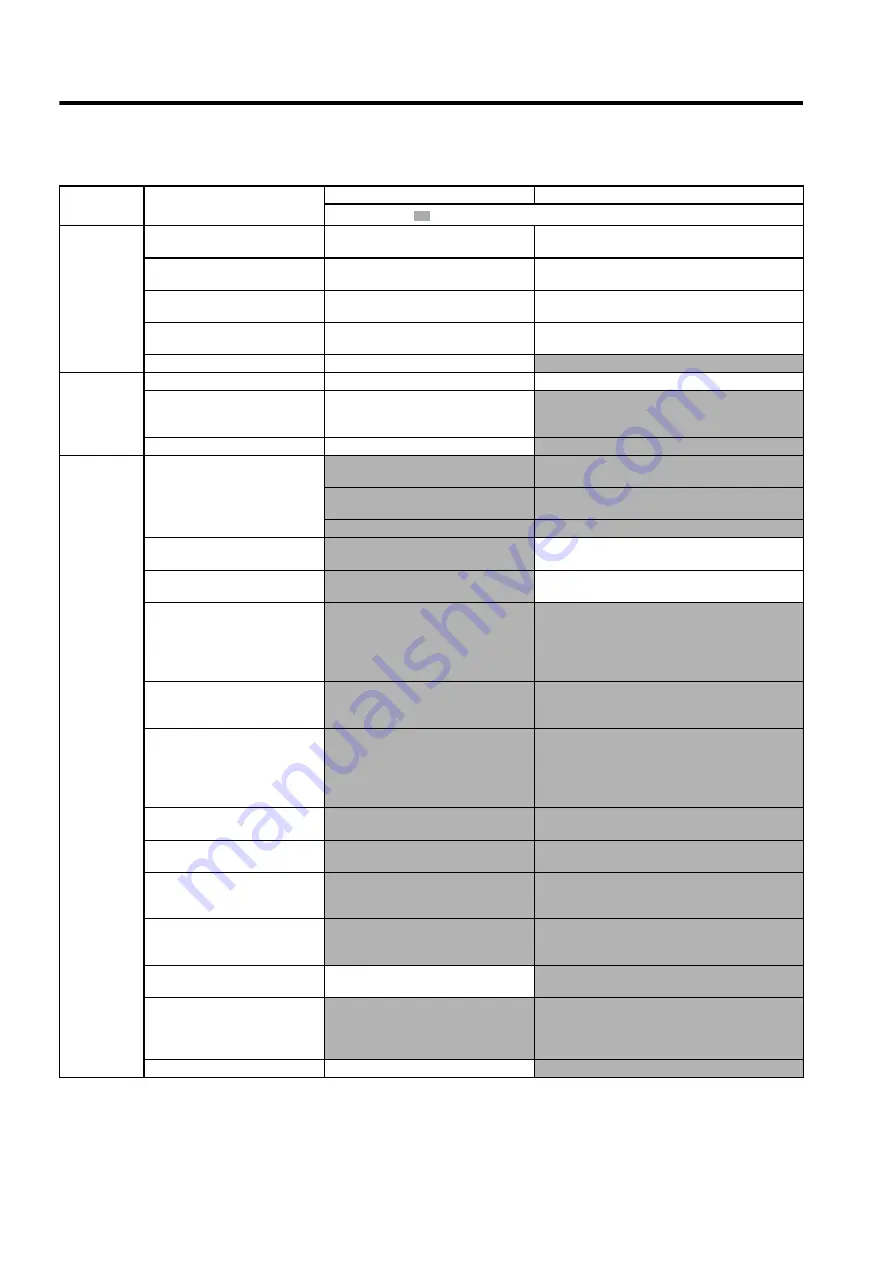

10 Inspection, Maintenance, and Troubleshooting

10.1.7 Troubleshooting for Malfunction without Alarm Display

10-18

Servomotor

Rotates With-

out Refer-

ence Input

Speed control: Speed reference input

is incorrect.

Check V-REF and SG to confirm if the con-

trol method and the input are agreed.

Correct the control mode selection parameter, or the

input correctly.

Torque control: Torque reference

input is incorrect.

Check V-REF and SG to confirm if the con-

trol method and the input are agreed.

Correct the control mode selection parameter, or the

input correctly.

Speed reference offset is error.

The SERVOPACK offset is adjusted incor-

rectly.

Adjust the SERVOPACK offset correctly.

Position control: Reference pulse

input is incorrect.

Check Pn200.0 reference pulse form or sign

+ pulse signal.

Correct the control mode selection parameter, or the

input correctly.

A SERVOPACK fault occurred.

A SERVOPACK board fault occurred.

Replace the SERVOPACK.

DB (dynamic

brake) Does

Not Operate

Improper parameter setting

Check the setting of parameter Pn001.0.

Correct the parameter setting.

DB resistor disconnected

Check if excessive moment of inertia,

motor overspeed, or DB frequently acti-

vated occurred.

Replace the SERVOPACK, and reconsider the load.

DB drive circuit fault

DB circuit parts are faulty.

Replace the SERVOPACK.

Abnormal

Noise from

Servomotor

Mounting not secured

Check if there are any loosen mounting

screws.

Tighten the mounting screws.

Check if there are misalignment of cou-

plings.

Align the couplings.

Check if there are unbalanced couplings.

Balance the couplings.

Defective bearings

Check for noise and vibration around the

bearings.

If any problems, contact your Yaskawa representative.

Vibration source on the driven

machine

Any foreign matter, damages, or deforma-

tion on the machine movable section.

Contact the machine manufacturer.

Noise interference due to incorrect

input signal wire specifications

The specifications of input signal wires

must be:

Twisted-pair or twisted-pair shielded wire

with core 0.12 mm

2

(0.0002 in

2

) min. and

tinned annealed copper twisted wire.

Use the specified input signal wires.

Noise interference due to long dis-

tance of input signal line

The wiring distance must be 3 m (9.84 ft)

max. and the impedance a few hundreds

ohm max.

Shorten the wiring distance for input signal line to the

specified value.

Noise interference due to incorrect

encoder cable specifications

The specifications of encoder cable must

be:

Twisted-pair or twisted-pair shielded wire

with core 0.12 mm

2

(0.0002 in

2

) min. and

tinned annealed copper twisted wire.

Use the specified encoder cable.

Noise interference due to long

encoder cable wiring distance

The wiring distance must be 20 m(65.6 ft)

max.

Shorten the encoder cable wiring distance to the speci-

fied value.

Noise due to damaged encoder cable

Check if the encoder cable is not damaged

or bent.

Modify the encoder cable layout.

Excessive noise to the encoder cable

Check if the encoder cable is bundled with

high-current line or near the high-current

line.

Install a surge suppressor to the encoder cable.

FG electrical potential varies by

influence of such machines on the

servomotor side as welders.

Check if the machine is correctly grounded.

Ground the machine separately from PG side FG.

SERVOPACK pulse counting error

due to noise

Check if there is noise interference on the

signal line from encoder.

Take measure against noise for the encoder wiring.

Excessive vibration and shock to the

encoder

Vibration from the machine occurred or ser-

vomotor installation is incorrect.

(Mounting surface accuracy, fixing, align-

ment, etc.)

Reduce vibration from the machine, or secure the servo-

motor installation.

Encoder fault

An encoder fault occurred.

Replace the servomotor.

Table 10.8 Troubleshooting for Malfunction without Alarm Display (Cont’d)

Symptom

Cause

Inspection

Corrective Actions

: Turn OFF the servo system before executing operations.

Summary of Contents for SGDH

Page 435: ...8 3 8...