4.2 Basic Functions Settings

4-25

4

Ope

rat

ion

4.2.11

Setting Motor Overload Detection Level

In this SERVOPACK, the detection timing of the warnings and alarms can be changed by changing how to

detect an overload warning (A.910) and overload (low load) alarm (A.720).

The overload characteristics and the detection level of the overload (high load) alarm (A.710) cannot be

changed.

(1) Changing Detection Timing of Overload Warning (A.910)

The overload warning level is set by default to 20% so that an overload warning is detected in 20% of the time

required to detect an overload alarm. The time required to detect an overload warning can be changed by

changing the setting of the overload warning level (Pn52B). This protective function enables the warning out-

put signal (/WARN) to serve as a protective function and to be output at the best timing for your system.

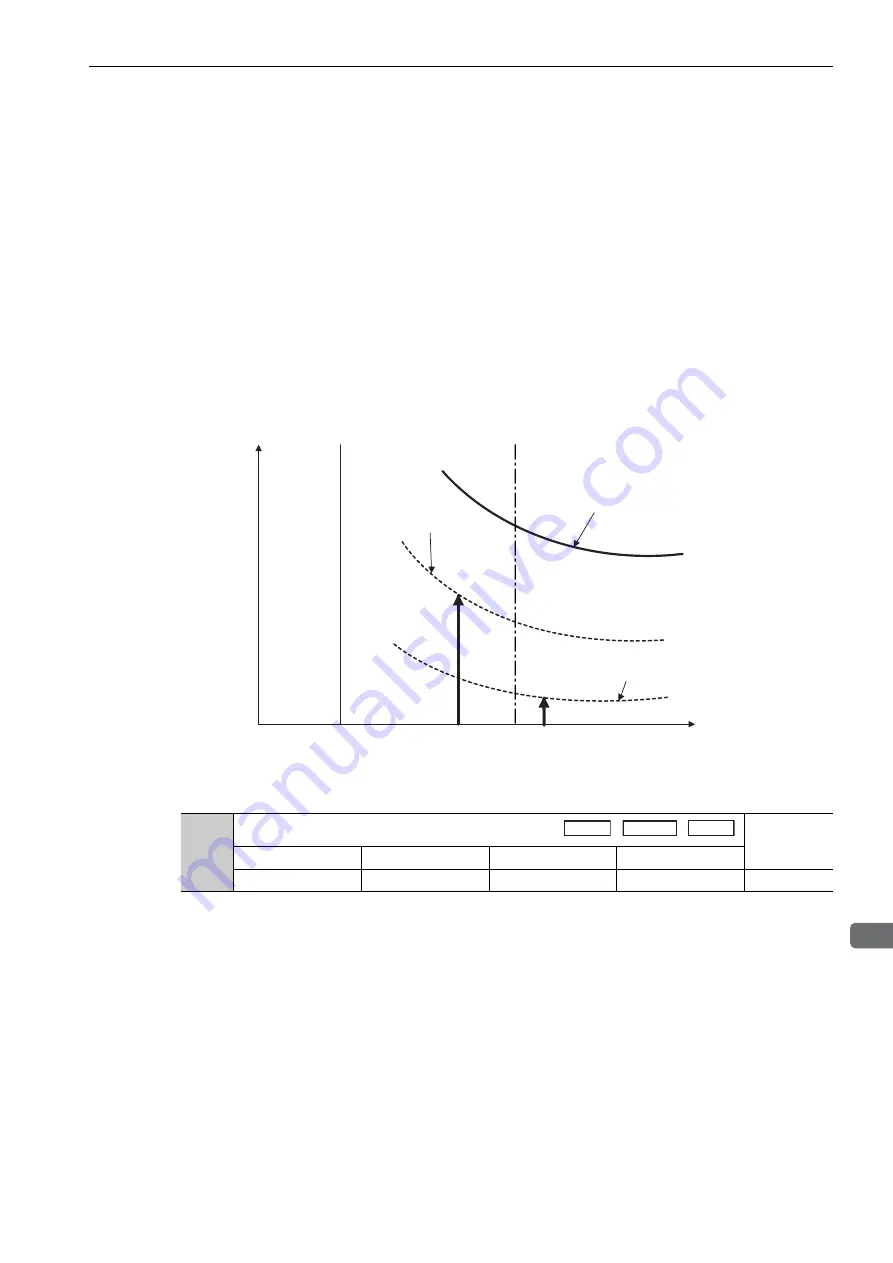

The following graph shows an example of the detection of an overload warning when the overload warning

level (Pn52B) is changed from 20% to 50%. An overload warning is detected in half of the time required to

detect an overload alarm.

Note: For details, refer to

Overload Characteristics

listed in the section for the relevant servomotor in the

Large-Capacity

Σ

-V Series Product Catalog

(No.: KAEP S800000 86).

Pn52B

Overload Warning Level

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

1 to 100

1%

20

Immediately

Setup

200%

100%

Overload detection time

Detection curve of

overload alarm

Detection curve of overload warning

when Pn52B = 20% (factory setting)

Detection curve of

overload warning when

Pn52B = 50%

Torque reference [%]

Rotation

Speed

Position

Torque