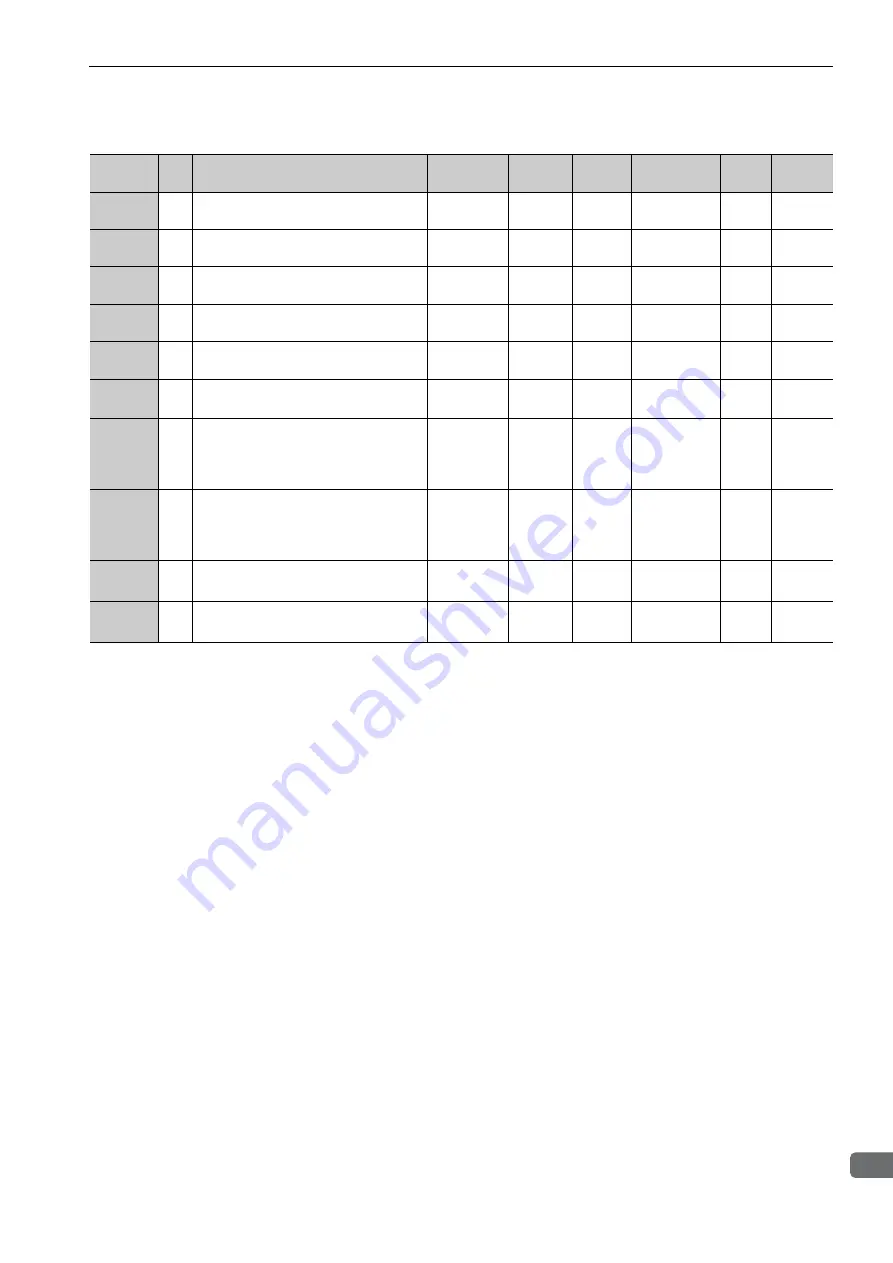

10.1 List of Parameters

10-23

10

Ap

pend

ix

Pn550

2

Analog Monitor 1 Offset Voltage

-10000 to

10000

0.1 V

0

Immediately

Setup

5.1.3

Pn551

2

Analog Monitor 2 Offset Voltage

-10000 to

10000

0.1 V

0

Immediately

Setup

5.1.3

Pn552

2

Analog Monitor

Magnification (

×

1)

-10000 to

10000

×

0.01

100

Immediately

Setup

5.1.3

Pn553

2

Analog Monitor

Magnification (

×

2)

-10000 to

10000

×

0.01

100

Immediately

Setup

5.1.3

Pn560

2

Remained Vibration

Detection Width

1 to 3000

0.1%

400

Immediately

Setup

5.7.1

Pn561

2

Overshoot Detection Level

0 to 100

1%

100

Immediately

Setup

5.3.1

5.4.1

Pn600

2

Regenerative Resistor Capacity

*2

Depends on

SERVO-

PACK

Capacity

*3

10 W

0

Immediately

Setup

3.8.3

Pn601

2

Dynamic Brake Resistor Capacity

0 or higher

(Max. value

depends on

model.)

*3

10 W

0

Immediately

Setup

3.9.2

Pn621 to

Pn628

*4

–

SERVOPACK: Safety Module Parame-

ters

–

–

–

–

–

–

Pn800 to

Pn95F

*5

2

Reserved (Do not change.)

–

–

0

–

–

–

∗2.

Normally set to "0." When using an external regenerative resistor, set the capacity (W) of the regenerative resistor

unit.

∗3.

The upper limit is the maximum output capacity (W) of the SERVOPACK.

∗4.

These parameters can be set in SERVOPACKs with safety modules. For details, refer to

Σ

-V Series User’s Manual,

Safety Module

(No.: SIEP C720829 06).

∗5.

For details on Pn800 to Pn95F, refer to the manual of the connected command option module.

(cont’d)

Parameter

No.

Size

Name

Setting

Range

Units

Factory

Setting

When

Enabled

Classi-

fication

Reference

Section