3.8

Special Wiring

143

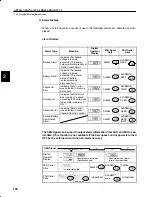

c) The following is an example of wiring for noise control.

Noise filter

*

1

Servomotor

(Red)

(White)

(Blue)

(Green)

DR2

Servopack

(Casing)

•

Operation relay se-

quence

•

Signal generation cir-

cuit (provided by cus-

tomer)

Wire with a thickness of

3.5 mm

2

or more

Ground plate

Ground: one-line grounding

(at least class 3 grounding)

(Casing)

(Casing)

(Casing)

(Casing)

3.5 mm

2

or more

100 or

200 VAC

3.5 mm

2

or more

Motor

output

line

shield

*2

3.5 mm

2

or more

* 1 When using a noise filter, always observe the following wiring instructions:

*2 Normally, motor output line shield is not required.

Note

1 For a ground wire to be connected to the casing, use a thick wire with a thick

ness of at least 3.5 mm

2

(preferably, plain stitch cooper wire).

However, be aware that max. connectable size of ground terminal

of

Servopack is 2.5mm

2

.

2 For wires indicated by P

↕

, use twisted-pair cables whenever possible.

2)

Correct Grounding

•

Always ground the motor ground terminal.

Always connect servomotor ground terminal FG (green) to the Servopack ground termi-

nal . Be sure to ground the ground terminal .

•

If the servomotor is grounded via the machine, a switching noise current will flow from

the Servopack power unit through motor stray capacitance. The above grounding is re-

quired to prevent the adverse effects of switching noise.

•

If the reference input line receives noise, do the following.

3