SERVO SELECTION AND DATA SHEETS

5.4.1

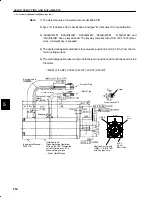

Servomotor Dimensional Drawings

cont.

256

•

750 W (1.01 HP)

Encoder Lead

Encoder Plug

Motor Plug

Protective Tube

(Black)

Incremental Encoder

2048 P/R

Cross-section Y-Y

Holding Brake

(Deenergisation Operation)

Voltage: 90 VDC, Dissipated

current (Reference): 0.15 A

Brake Holding Torque= Motor Rated Torque

Brake

Lead

Motor Lead (Teflon wire) AWG22

UL1828 or UL3534

34 (1.34)

111 (4.37)

15 (0.59)

Screw

4-

φ

7 (

φ

0.28)

MTG Holes

Shaft end screw hole

(SGM-

08

A316B,

with key type only)

80 (3.15)

4

−

R8.2

φ

90

(

φ

3.54)

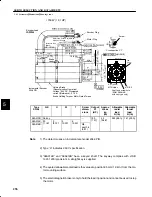

Type

SGM-

QK

U

W

T

Screw

dimen-

sions

Output

W

(HP)

Approx.

mass

kg

(lb)

Allowable

radial

load

N (lb)

Allowable

thrust

load

N (lb)

08A312B No key

−

750

(

)

4.3

(

)

392 (88.1) 147 (33.0)

08A314B 30

(

)

3

(

)

5

(

)

5

(

)

(1.01)

(9.48)

(

)

(

)

08A316B (1.18)

(0.12)

(0.20)

(0.20)

M5,

depth 8

(0.31)

Note

1) The detector uses an incremental encoder 2048 P/R.

2) Type “A” indicates 200 V specification.

3) “08A314B” and “08A316B” have a keyed shaft. The keyway complies with JIS B

1301-1976 (precision). A straight key is supplied.

4) The quoted allowable radial load is the value at a position 35 mm (1.38 in.) from the mo-

tor mounting surface.

5) The electromagnetic brake is only to hold the load in position and cannot be used to stop

the motor.

5