3.3 FT82 SERVOPACK with MECHATROLINK-III Communications References

3.3.6 Troubleshooting Warnings

3-130

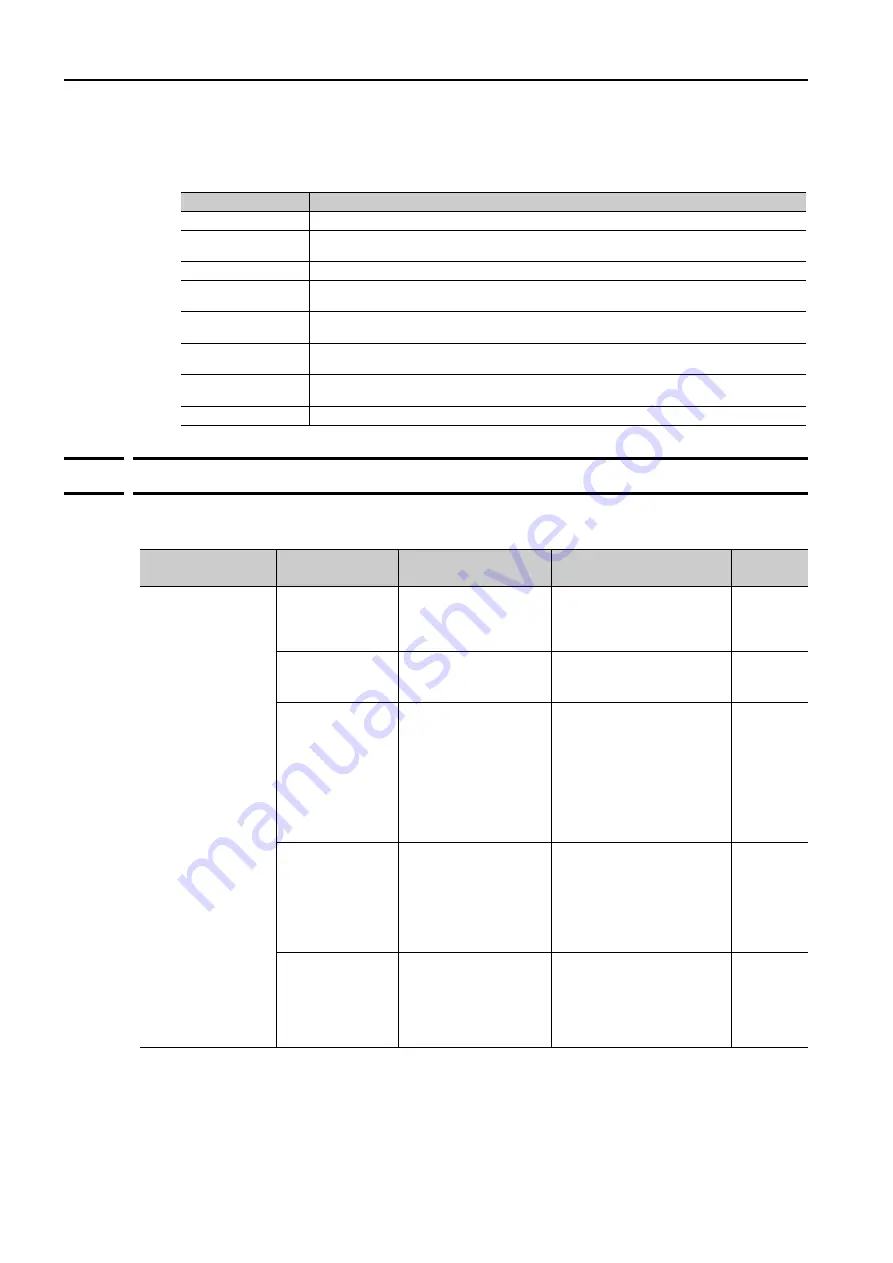

Note: 1. A warning code is not output unless you set Pn001 to n.1

(Output both alarm codes and warning

codes).

2. Use Pn008 = n.

X

(Warning Detection Selection) to control warning detection.

However, the following warnings are not affected by the setting of Pn008 = n.

X

and other parameter

settings are required in addition to Pn008 = n.

X

.

3.3.6

Troubleshooting Warnings

The causes of and corrections for the warnings are given in the following table. Contact your

Yaskawa representative if you cannot solve a problem with the correction given in the table.

Warning

Parameters That Must Be Set to Select Warning Detection

A.911

Pn310 = n.

X (Vibration Detection Setting)

A.923

–

(Not affected by the setting of Pn008 = n.

X

.)

A.930

Pn008 = n.

X (Low Battery Voltage Alarm/Warning Selection)

A.942

Pn423 = n.

X

(Speed Ripple Compensation Information Disagreement Warning

Detection Selection)

A.94A to A.960 and

A.97A to A.97b

Pn800=n.

X

(Warning Check Masks)

A.971

Pn008 = n.

X (Low Battery Voltage Alarm/Warning Selection)

(Not affected by the setting of Pn008 = n.

X

.)

A.9A0

Pn00D = n.X

(Overtravel Warning Detection Selection)

(Not affected by the setting of Pn008 = n.

X

.)

A.9b0

Pn00F = n.

X (Preventative Maintenance Selection)

Warning Number:

Warning Name

Possible Cause

Confirmation

Correction

Reference

A.900:

Position Deviation

Overflow

The Servomotor

U, V, and W wiring

is not correct.

Check the wiring of the

Servomotor’s Main Cir-

cuit Cables.

Make sure that there are no

faulty connections in the

wiring for the Servomotor

and encoder.

–

A SERVOPACK

gain is too low.

Check the SERVO-

PACK gains.

Increase the servo gain,

e.g., by using autotuning

without a host reference.

*

The acceleration

of the position ref-

erence is too high.

Reduce the reference

acceleration and try

operating the SERVO-

PACK.

Reduce the acceleration of

the position reference using

a MECHATROLINK com-

mand. Or, smooth the posi-

tion reference acceleration

by selecting the position

reference filter (ACCFIL)

using a MECHATROLINK

command.

–

The excessive

position deviation

alarm level (Pn520

×

Pn51E/100) is

too low for the

operating condi-

tions.

Check excessive posi-

tion deviation alarm

level (Pn520

×

Pn51E/

100) to see if it is set to

an appropriate value.

Optimize the settings of

Pn520 and Pn51E.

*

A failure occurred

in the SERVO-

PACK.

–

Turn the power supply to

the SERVOPACK OFF and

ON again. If an alarm still

occurs, the SERVOPACK

may be faulty. Replace the

SERVOPACK.

–

Continued on next page.