4.3 FT82 SERVOPACK with MECHATROLINK-III Communications References

4.3.1 List of Servo Parameters

4

Parameter Li

s

t

s

4-105

*1.

Refer to the following manual for details.

Σ

-7-Series

Σ

-7S SERVOPACK with MECHATROLINK-III Communications References Product Manual (Manual

No.: SIEP S800001 28)

*2.

Refer to the following manual for details.

Σ

-7-Series AC Servo Drive MECHATROLINK-III Communications Standard Servo Profile Command Manual

(Manual No.: SIEP S800001 31)

*3.

Set a percentage of the motor rated torque.

*4.

These parameters are for SERVOPACKs with a Safety Module. Refer to the following manual for details.

Σ

-V-Series/

Σ

-V-Series for Large-Capacity Models/

Σ

-7-Series User’s Manual Safety Module (Manual No.: SIEP

C720829 06)

*5.

Normally set this parameter to 0. If you use an External Regenerative Resistor, set the capacity (W) of the Exter-

nal Regenerative Resistor.

*6.

The upper limit is the maximum output capacity (W) of the SERVOPACK.

*7.

These parameters are for SERVOPACKs with the dynamic brake option. Refer to the following manual for

details.

Σ

-7-Series AC Servo Drive

Σ

-7S/

Σ

-7W SERVOPACK with Hardware Option Specifications Dynamic Brake Prod-

uct Manual (Manual No.: SIEP S800001 73)

*8.

The SGLFW2 is the only Yaskawa Linear Servomotor that supports this function.

*9.

Enabled only when Pn61A is set to n.

2 or n.

3.

*10.

This parameter is valid only when the MECHATROLINK-III standard servo profile is used.

*11.

The parameter setting is enabled after SENS_ON command execution is completed.

*12.

Change the setting when the reference is stopped (i.e., while DEN is set to 1). If you change the setting during

operation, the reference output will be affected.

*13.

The settings are updated only if the reference is stopped (i.e., only if DEN is set to 1).

*14.

Refer to the following manual for details.

Σ

-7-Series AC Servo Drive MECHATROLINK-II Communications Command Manual (Manual No.: SIEP S800001

30)

*15.

This parameter is valid only when the MECHATROLINK-II-compatible profile is used.

*16.

The setting of Pn842 is valid while Pn817 is set to 0.

*17.

The setting of Pn844 is valid while Pn818 is set to 0.

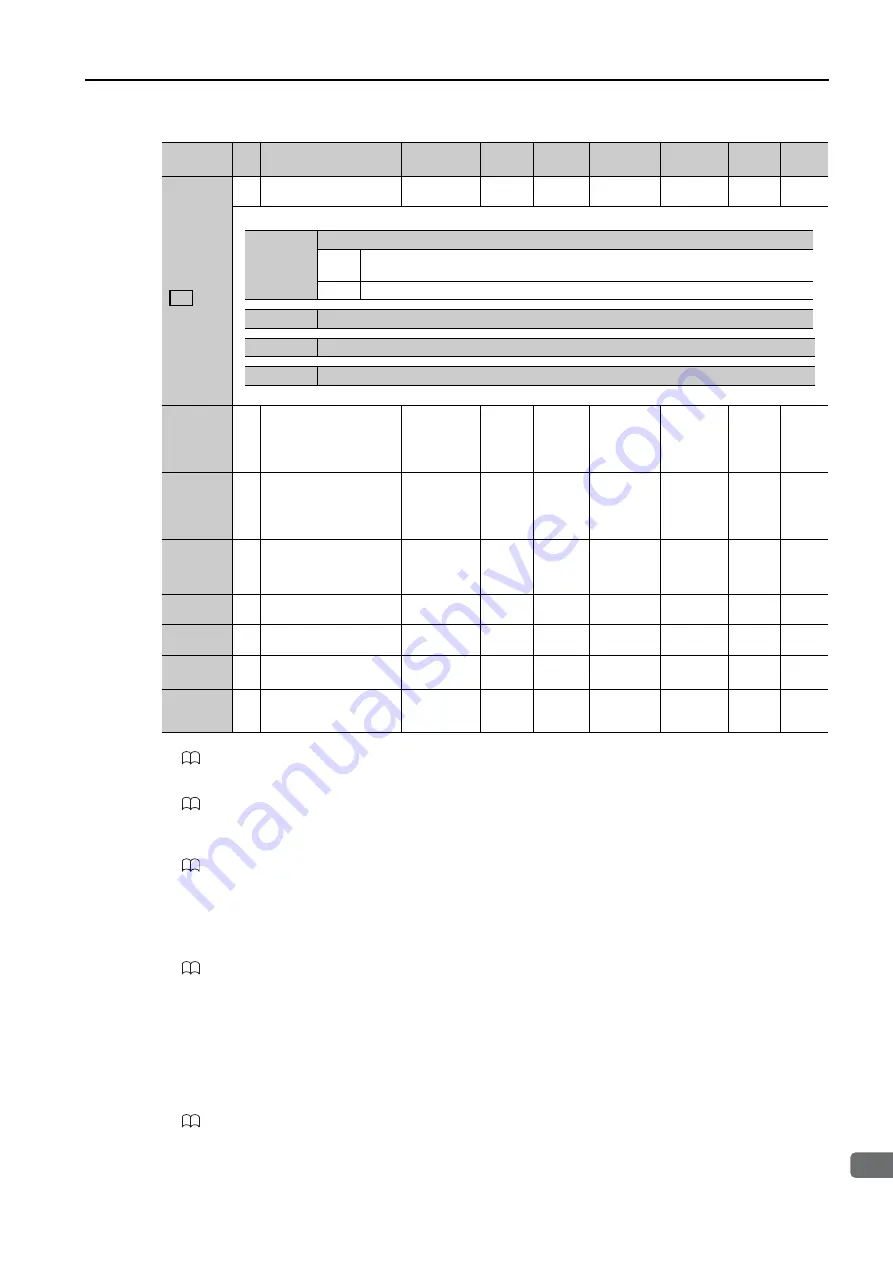

Pn884

2

Communications Con-

trols 2

0000h to

0001h

–

0000h

All

Immedi-

ately

Setup

*2

Pn88A

2

MECHATROLINK

Receive Error Counter

Monitor

(for maintenance, read

only)

0 to 65,535

–

0

All

Immedi-

ately

Setup

–

Pn890 to

Pn8A6

4

Command Data Moni-

tor during Alarm/Warn-

ing

(for maintenance, read

only)

0h to

FFFFFFFFh

–

0h

All

Immedi-

ately

Setup

*2

Pn8A8 to

Pn8BE

4

Response Data Monitor

during Alarm/Warning

(for maintenance, read

only)

0h to

FFFFFFFFh

–

0h

All

Immedi-

ately

Setup

*2

Pn900

2

Number of Parameter

Banks

0 to 16

–

0

All

After

restart

Setup

*2

Pn901

2

Number of Parameter

Bank Members

0 to 15

–

0

All

After

restart

Setup

*2

Pn902 to

Pn910

2

Parameter Bank Mem-

ber Definition

0000h to

08FFh

–

0h

All

After

restart

Setup

*2

Pn920 to

Pn95F

2

Parameter Bank Data

(Not saved in nonvolatile

memory.)

0000h to

FFFFh

–

0h

All

Immedi-

ately

Setup

*2

Continued from previous page.

Parameter

No.

Siz

e

Name

Setting

Range

Setting

Unit

Default

Setting

Applicable

Motors

When

Enabled

Classi-

fication

Refer-

ence

M3

*10

n.

X

MECHATROLINK Communications Error Holding Brake Signal Setting

0

Maintain the status set by the BRK_ON or BRK_OFF command when a MECHA-

TROLINK communications error occurs.

1

Apply the holding brake when a MECHATROLINK communications error occurs.

n.

X

Reserved parameter (Do not change.)

n.

X

Reserved parameter (Do not change.)

n.X

Reserved parameter (Do not change.)