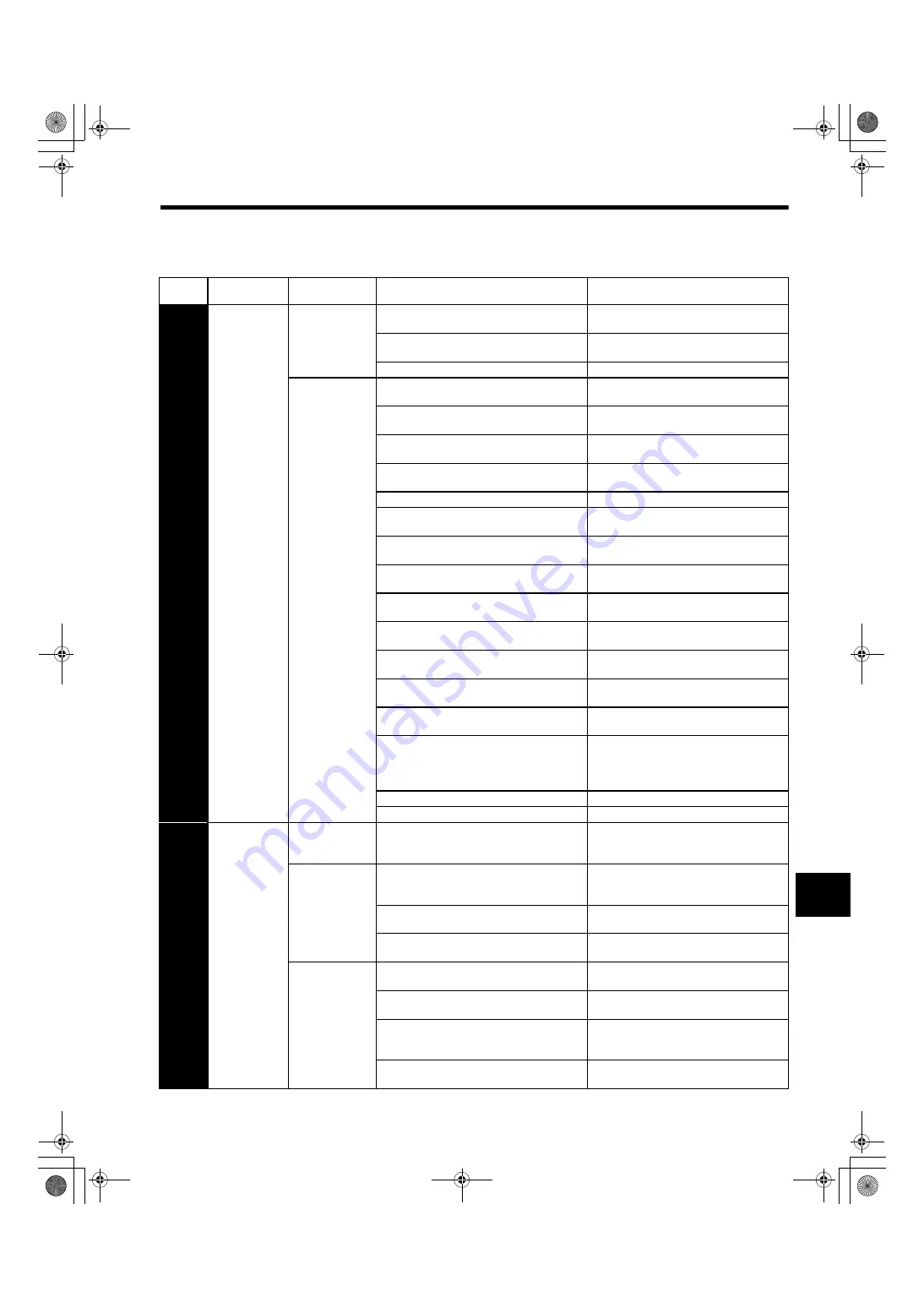

9.1 Troubleshooting

9-7

9

A.100

Overcurrent

(An overcurrent

flowed through

the IGBT)

or

Heat Sink

Overheated

(

Heat sink of

SERVOPACK

was overheated.)

Occurred when the

control power sup-

ply was turned

ON.

The overload alarm has been reset by turning

OFF the power too many times.

Change the alarm resetting method.

The connection between SERVOPACK board

and thermostat switch is incorrect.

Replace the SERVOPACK.

A SERVOPACK board fault occurred.

Replace the SERVOPACK.

Occurred when the

main circuit power

supply was turned

ON or an

overcurrent

occurred while the

servomotor was

running.

The connection between grounding and U, V, or

W is incorrect.

Check the wiring and connect correctly.

The grounding line has contact with other termi-

nals.

Check the wiring and connect correctly.

A short-circuit occurred between U, V and W of

the servomotor cable and the grounding.

Repair or replace the servomotor cable.

A short-circuit of phase U, V, and W of the servo-

motor cable occurred.

Repair or replace the servomotor cable.

The wiring of regenerative resistor is incorrect.

Check the wiring and connect correctly.

A short-circuit between U, V and W of the

SERVOPACK and the grounding occurred.

Replace the SERVOPACK.

A SERVOPACK fault occurred (current feedback

circuit, power transistor or board fault).

Replace the SERVOPACK.

A short-circuit between U, V and W of the servo-

motor and the grounding occurred.

Replace the servomotor.

A short-circuit of phase U, V, and W of the servo-

motor occurred.

Replace the servomotor.

A fault occurred in the dynamic brake circuit.

Replace the SERVOPACK, and reduce the

load, or reduce the number of rotations used.

Frequent activation of dynamic brake (occur-

rence of DB overload alarm)

Replace the SERVOPACK, and reduce the DB

operation frequency.

The overload alarm has been reset by turning

OFF the power too many times.

Change the alarm resetting method.

Overload or regenerative power exceeds the

regenerative resistor capacity.

Reconsider the load and operation conditions.

Incorrect mounting of SERVOPACK (direction,

distance to other devices)

Heat radiation of the panel or heat around the

panel.

The ambient temperature for SERVOPACK

must be 55

°

C or less.

A SERVOPACK fan fault occurred.

Replace the SERVOPACK.

A SERVOPACK fault occurred.

Replace the SERVOPACK.

A.300

Regeneration

Error Detected

(Detected when

the power to the

main circuit was

turned ON)

Occurred when the

control power sup-

ply was turned ON

A SERVOPACK board fault occurred.

Replace the SERVOPACK.

Occurred when the

main circuit power

supply was turned

ON.

Pn600 is set to a value other than “0” for servo-

motor 400 W or less, and an external regenera-

tive resistor is not connected.

Connect a external regenerative resistor, or set

Pn600 to “0” if an external regenerative resis-

tor is not connected.

Check for wrong wiring or disconnection of

regenerative resistor.

Correct the wiring for the external regenerative

resistor.

A SERVOPACK fault occurred (such as regener-

ative transistor and voltage sensor fault).

Replace the SERVOPACK.

Occurred during

normal operation.

Check for wrong wiring and disconnection of

regenerative resistor.

Correct the wiring for the external regenerative

resistor.

The jumper between B2 and B3 is removed for

the servomotor 500 W or more.

Correct the wiring.

Regenerative resistor is disconnected, so the

regenerative energy became excessive.

Replace the regenerative resistor or replace the

SERVOPACK . Reconsider the load and opera-

tion conditions.

A SERVOPACK fault, such as regenerative tran-

sistor and voltage sensor fault, occurred.

Replace the SERVOPACK.

Table 9.3 Alarm Display and Troubleshooting (Cont’d)

Alarm

Display

Alarm Name

Situation at Alarm

Occurrence

Cause

Corrective Actions

SIEPS80000025.book 7 ページ 2004年10月25日 月曜日 午前11時57分