YASKAWA

SIEP C730600 88F MECHATROLINK-III Technical Manual

17

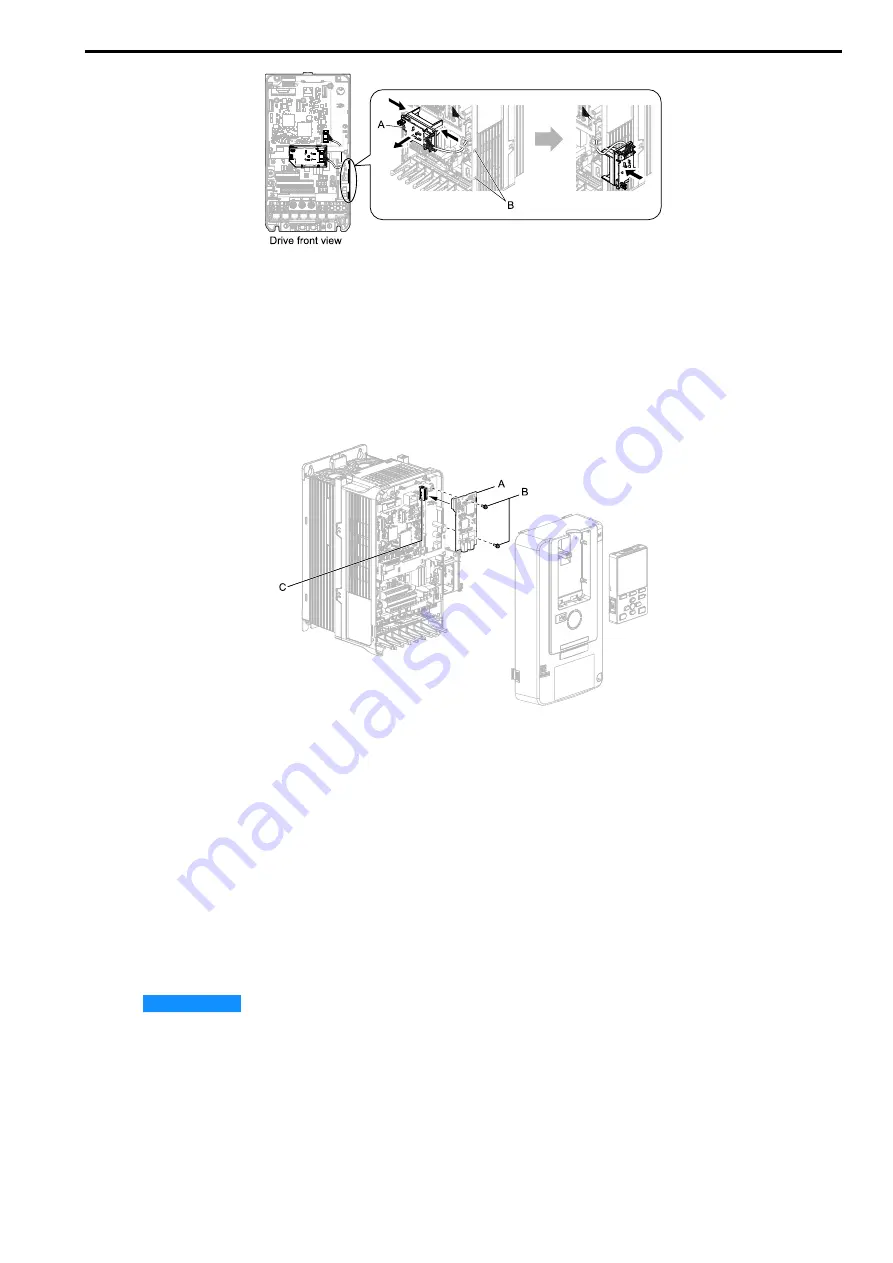

A - LED Status Ring board

B - Temporary placement holes

Figure 5.11 Remove the LED Status Ring Board

4.

Insert the option (A) into the CN5-A connector (C) on the drive and use the included screws (B) to put it in

place.

• Tighten both screws to 0.5 to 0.6 N•m (4.4 to 5.3 in•lb).

Note:

1. A ground wire is not necessary. The option package ships with three screws and a ground wire for installation on other

product series. Do not use the ground wire or the extra screw.

2. Only two screws are necessary to install the option on GA700, GA800, CR700, and CH700 drives.

A - Option

B - Included screws

C - Connector CN5-A

Figure 5.12 Install the Option

5.

Select the proper MECHATROLINK-III dedicated communication cable according to

.

Firmly connect the MECHATROLINK-III communication cable to option communication connector CN1 or

CN2. Isolate the MECHATROLINK-II communications cables from main circuit wiring and other electrical

and power lines. Ensure the cable end is firmly connected (see

). Refer to

Communications Cables on page 18

for more information.

Note:

Maximum transmission distance is 100 m (328 ft). Minimum wiring distance between stations is 0.2 m (7.9 in).

6.

Reattach the LED Status Ring board (E). Use the open space provided inside the LED Status Ring board

to route option wiring. Reattach the drive front cover (C) and the keypad (D).

Refer to the manual packaged with the drive for information on how to reattach the LED Status Ring

board.

NOTICE

Do not pinch cables between the front cover or the LED Status Ring board and the drive. Failure to

comply could cause erroneous operation.

Note:

• Replace the keypad connector then install the keypad.

• At that time, insert the keypad connector tab into the drive.