24

YASKAWA

SIEP C730600 88F MECHATROLINK-III Technical Manual

◆

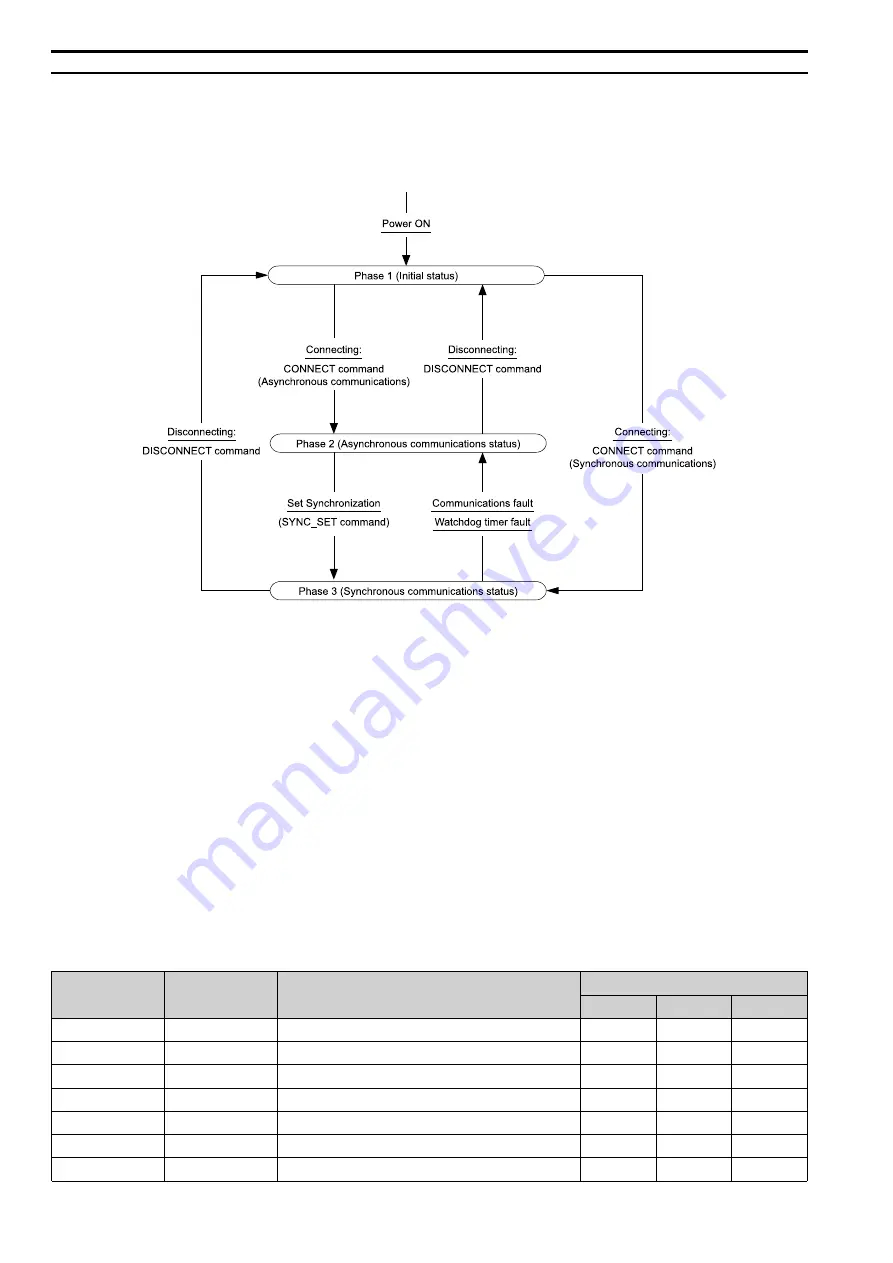

Communication Phases

The SI-ET3 option changes status after receiving a command code or fault from the master as shown in the

following figure.

The communication phases determine the available commands. Refer to

and

for more

information.

Figure 7.1 Communication Phases

■

Phase 1: Initial status after power ON

Operation proceeds with a default transmission cycle of 2 ms. The transmission cycle is changed to the time

indicated in the synchronous frame when a CONNECT command is received from the master. Then the phase

moves to phase 2 or phase 3 after a response to the CONNECT command is returned.

Even if a transfer fault is detected in phase 1, no fault notification is provided.

■

Phase 2: Asynchronous communications

All SI-ET3 commands can be used. Phase 2 starts to count the watchdog timer in the communications frame The

phase moves to phase 3 when a SYNC_SET command is received, and it moves to phase 1 when a

DISCONNECT command is received.

■

Phase 3: Synchronous communications

Watchdog timer faults in the communications frame are detected. The phase moves to phase 1 if the

DISCONNECT command is received. The phase moves to phase 2 if a reception fault or a watchdog timer fault is

detected.

Table 7.2 Main Command Communication Phases

Command

Code

(Hex.)

Contents

Communication Phases

1

2

3

NOP

00

No Operation Command

-

○

○

PRM_RD

01

Read Parameter Command

-

○

○

PRM_WR

02

Write Parameter Command

-

○

○

ID_RD

03

Read ID Number Command

-

○

○

CONFIG

04

Setup Device Command

-

○

○

ALM_RD

05

Read Alarm and Warning Command

-

○

○

ALM_CLR

06

Clear Alarm and Warning Command

-

○

○