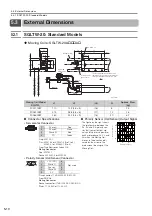

5.3 External Dimensions

5.3.5 SGLTW-50: High-efficiency Models

5

S

pecification

s

, Rating

s

, and Exter

nal Dimen

s

ion

s

of

SG

LT

S

ervomotor

s

5-21

5.3.5

SGLTW-50: High-efficiency Models

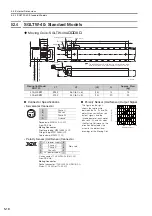

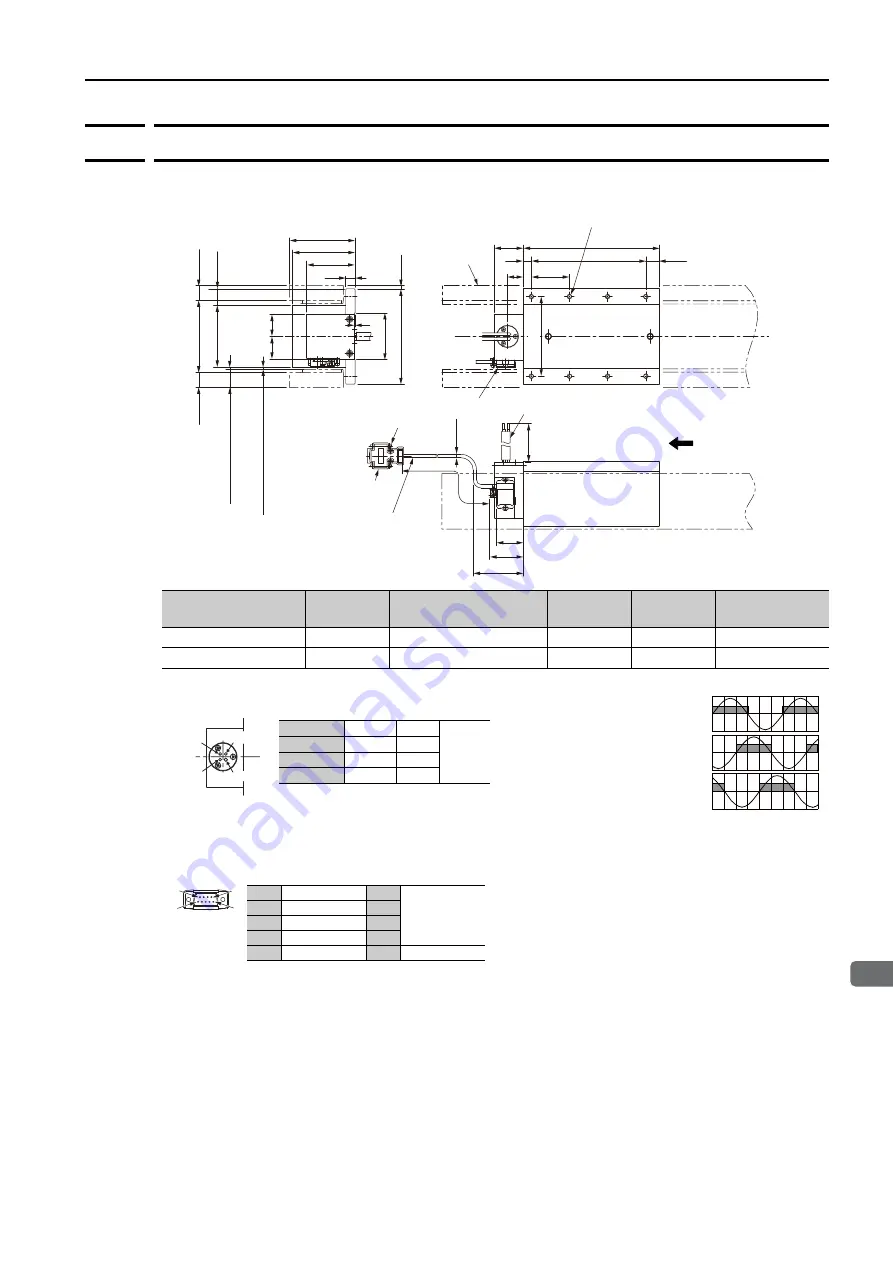

Moving Coils: SGLTW-50A

H

Moving Coil Model

SGLTW-

L1

L2

(L3)

N

Approx. Mass

[kg]

50A170H

170

144 (48

×

3)

(16)

8

6

50A320H

315

288 (48

×

6)

(17)

14

11

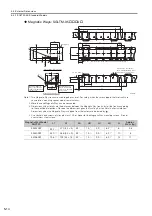

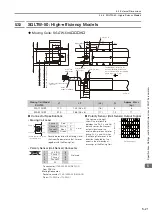

Connector Specifications

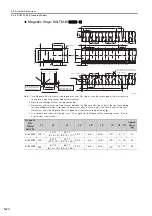

Polarity Sensor (Hall Sensor) Output Signal

•

Moving Coil Lead

The figure on the right

shows the relationship

between the Su, Sv, and Sw

polarity sensor (hall sensor)

output signals and the

inverse power of each motor

phase Vu, Vv, and Vw when

the Moving Coil moves in the

direction indicated by the

arrow in the dimensional

drawings of the Moving Coil.

Secure the lead from the Moving Coil of

the Linear Servomotor so that it moves

together with the Moving Coil.

•

Polarity Sensor (Hall Sensor) Connector

Pin connector: 17JE-23090-02 (D8C)-CG

From DDK Ltd.

Mating Connector

Socket connector: 17JE-13090-02 (D8C)A-CG

Studs: 17L-002C or 17L-002C1

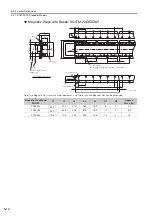

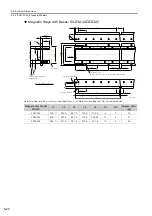

Magnetic Way

2

#4-40

UNC screws

Polarity sensor (hall sensor)

connector

Cable

UL20276, AWG28

(4.2 dia.)

Polarity sensor

(hall sensor)

Protective tube

Unit: mm

The Moving Coil moves in the

direction indicated by the arrow

when current flows in the following

phase sequence: U, V, W.

(Gap: 1.0 without magnet cover)

(Gap: 0.8 with magnet cover)

(23.1 without magnet cover)

(23.3 with magnet cover)

28

30

1

(4.1)

(90)

(85)

(19.1)

80

±

0.05

120

±

0.1

500

±

50

35

43

63 min.

20

±

0.1

500

±

50

100

±

0.15

(L3)

48

±

0.15

20

10

30

L1

N

×

M6

×

12

L2

(19.1)

12

60

81

62.5

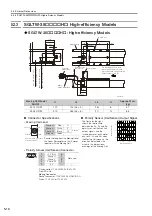

Vu

Vv

Vw

Su

Sv

Sw

0

180

360

540

Inverse power (V)

Electrical angle (

°

)

Phase V

Phase U

Ground

Phase W

(Viewed from the top surface

of the Moving Coil.)

Phase U

Red

U

2 mm

2

Phase V

White

V

Phase W

Black

W

Ground

Green

−

9

6

5

1

1

+5 V (DC)

6

Not used

2

Phase U

7

3

Phase V

8

4

Phase W

9

5

0 V

−

−