7.2 Installation Procedure

7.2.2 SGLF Servomotors (Models with F-type Iron Cores)

7-8

*

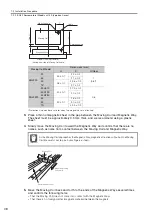

Dimensions in parentheses are for when the magnet cover is attached.

3.

Place a thin nonmagnetic sheet in the gap between the Moving Coil and Magnetic Way.

The sheet must be approximately 0.5 mm thick, and we recommend using a plastic

sheet.

4.

Slowly move the Moving Coil toward the Magnetic Way and confirm that there are no

noises, such as noise from contact between the Moving Coil and Magnetic Way.

5.

Move the Moving Coil back and forth to the ends of the Magnetic Ways several times

and confirm the following items.

•

That the Moving Coil does not come into contact with the Magnetic Ways

•

That there is no foreign matter (magnetic material) between the magnets

Moving Coil Model

Dimensions (mm)

H

P

G (Gap)

SGLFW-

20

45

±

0.1

22

±

0.2

1

(0.8)

*

35

21

±

0.2

50

58

±

0.1

25.8

±

0.2

1Z

27

±

0.2

SGLFW2-

30A070

40

±

0.1

27.5

±

0.2

0.8

30A120

20

±

0.2

30A230

45

50

±

0.1

26

±

0.2

90

30

±

0.2

1D

42.5

±

0.2

As the Moving Coil approaches the Magnetic Way, magnetic attraction will pull on the Moving

Coil. Be careful not to pinch your fingers or tools.

Gap, G

H

P

Moving Coil

Magnetic Way

Mounting hole

Side of Linear Servomotor

(viewed from side of Moving Coil cable)

Cable

Reference mark

Important

Nonmagnetic sheet

Move the Moving

Coil slowly.

Moving Coil