4 Operation

4.3.7 Setting Motor Overload Detection Level

4-22

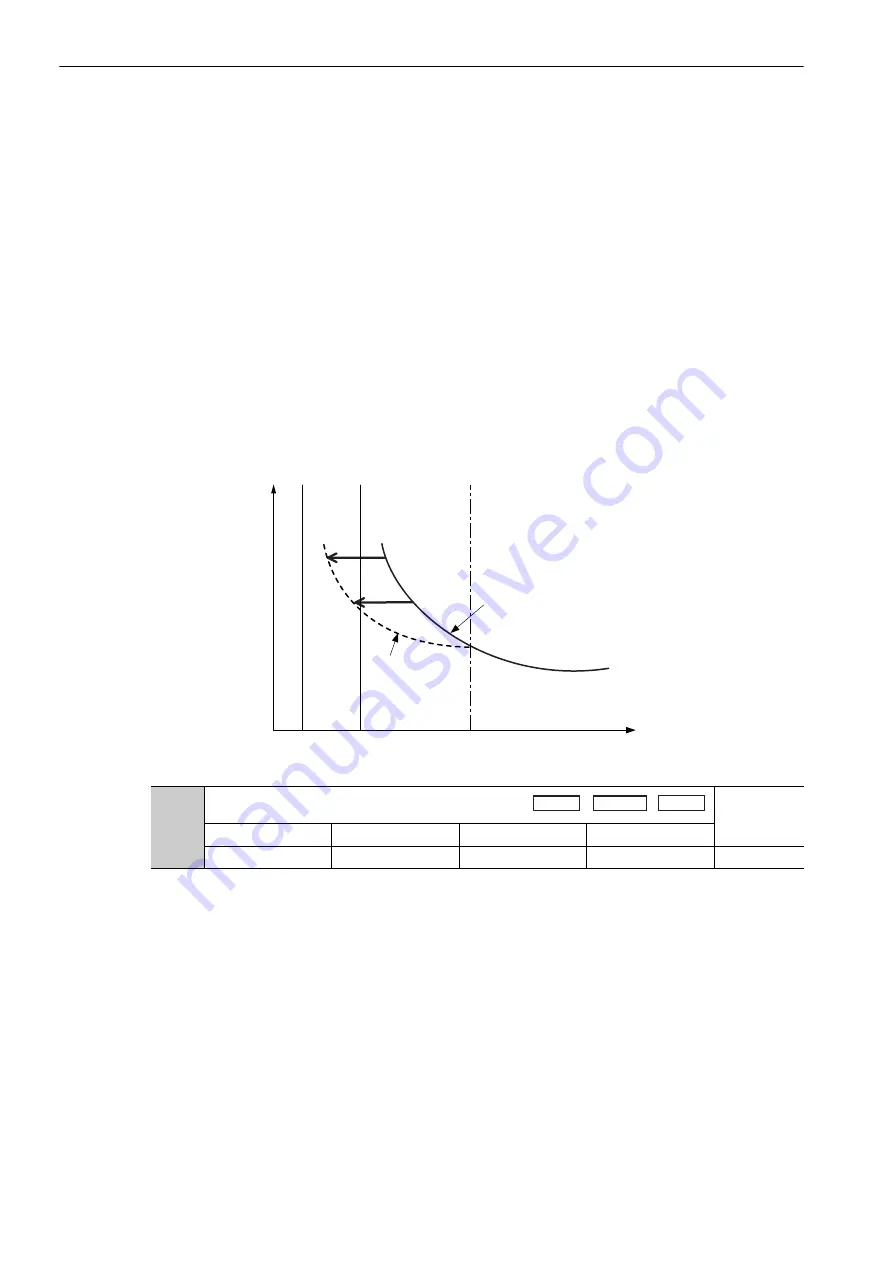

(2) Changing Detection Timing of Overload (Low Load) Alarm (A.720)

An overload (low load) alarm (A.720) can be detected earlier to protect the servomotor from overloading. The

time required to detect an overload alarm can be shortened by using the derated motor base current obtained

with the following equation.

Note: The detection level of the overload (high load) alarm (A.710) cannot be changed.

Motor base current

×

Derating of base current at detecting overload of motor (Pn52C)

= Derated motor base current

Motor base current: Threshold value of motor current to start calculation for overload alarm

Derating of base current at detecting overload of motor (Pn52C): Derating of motor base current

The following graph shows an example of the detection of an overload alarm when Pn52C is set to 50%. The

calculation for the overload of motors starts at 50% of the motor base current and then an overload alarm will

be detected earlier.

Changing the setting of Pn52C will change the detection timing of the overload alarm, so the time required to

detect the overload warning will also be changed.

Note: Refer to

SERVOPACK Overload Characteristics

in the multi-winding drive system catalog for details.

Pn52C

Derating of Base Current at Detecting Overload of

Motor

Classification

Setting Range

Setting Unit

Factory Setting

When Enabled

10 to 100

1%

100

After restart

Setup

Detection curve of

overload alarm when

Pn52C = 100% (factory setting)

Detection curve of

overload alarm

when Pn52C = 50%

Torque reference [%]

50%

Overload detection time

100%

200%

Rotation

Speed

Position

Torque