5 Adjustments

5.1.1 Adjustments

5-2

5.1

Type of Adjustments and Basic Adjustment Procedure

This section describes type of adjustments and the basic adjustment procedure.

5.1.1

Adjustments

Adjustments (tuning) are performed to optimize the responsiveness of the multi-winding drive unit.

The responsiveness is determined by the servo gain that is set in the multi-winding drive unit.

The servo gain is set using a combination of parameters, such as speed loop gain, position loop gain, filters,

friction compensation, and moment of inertia ratio. These parameters influence each other. Therefore, the

servo gain must be set considering the balance between the set values.

Generally, the responsiveness of a machine with high rigidity can be improved by increasing the servo gain. If

the servo gain of a machine with low rigidity is increased, however, the machine will vibrate and the respon-

siveness may not be improved. In such cases, it is possible to suppress the vibration with a variety of vibration

suppression functions in the multi-winding drive unit.

The servo gains are factory-set to appropriate values for stable operation. The following utility function can be

used to adjust the servo gain to increase the responsiveness of the machine in accordance with the actual con-

ditions. With this function, parameters related to adjustment above will be adjusted automatically and the need

to adjust them individually will be eliminated.

This section describes the following utility adjustment functions.

∗

With the multi-winding drive system, adjustment is performed only for moment of inertia calculation.

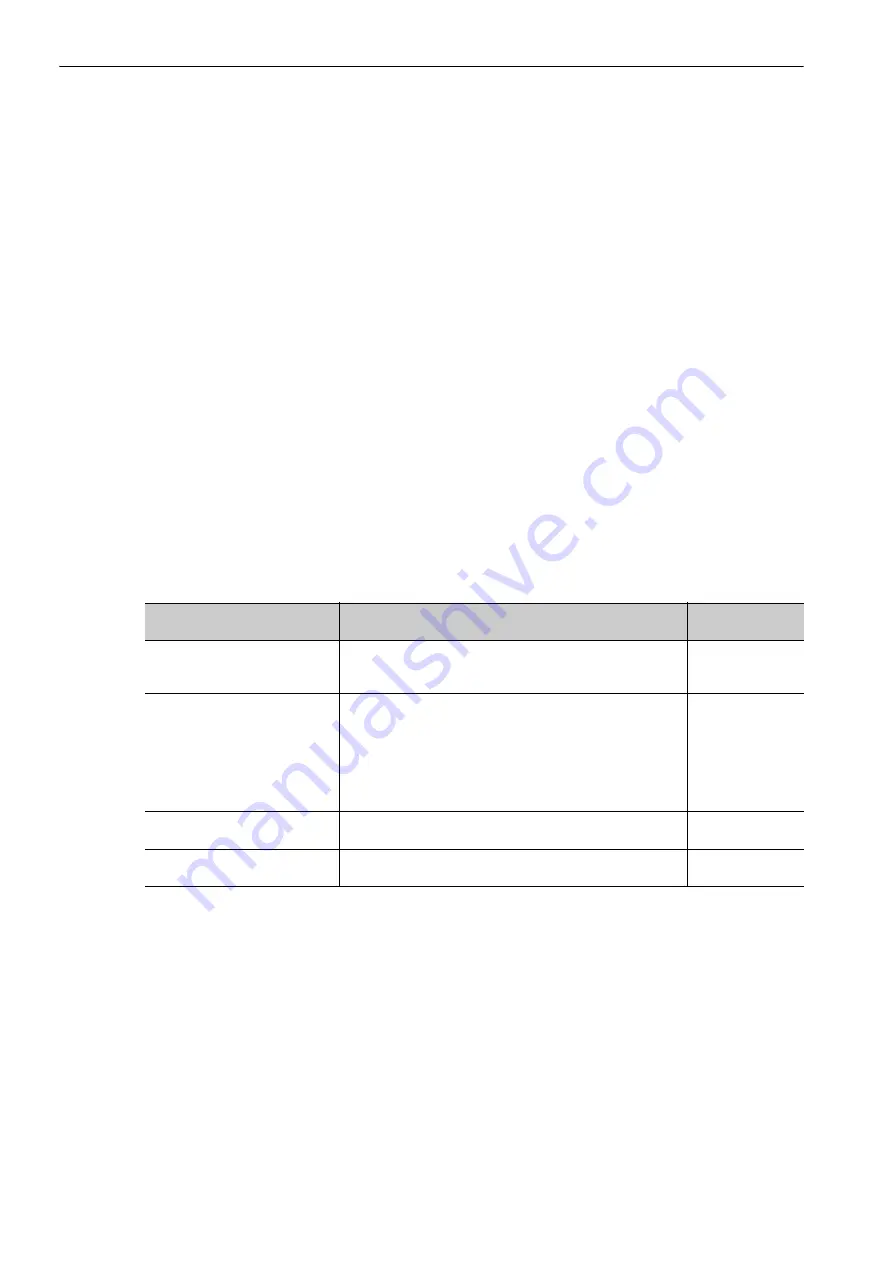

Utility Function for Adjustment

Outline

Applicable

Control Method

Advanced Autotuning (Fn201)

*

Automatic operation is performed with internal references in

the multi-winding drive unit to automatically adjust the

moment of inertia ratio.

Speed and Position

One-parameter Tuning

(Fn203)

The following parameters are manually adjusted with the posi-

tion or speed reference input from the host controller while the

machine is in operation.

• Gains (position loop gain, speed loop gain, etc.)

• Filters (torque reference filter, notch filter)

• Friction compensation

• Anti-resonance control adjustment function

Speed and Position

Anti-Resonance Control

Adjustment Function (Fn204)

This function effectively suppresses continuous vibration.

Speed and Position

Vibration Suppression

Function (Fn205)

This function effectively suppresses residual vibration if it

occurs when positioning.

Position