3.10 Selecting and Connecting a Dynamic Brake Unit

3-35

3

Wirin

g and

Co

nnectio

n

3.10.3

Setting the Dynamic Brake Unit

Use the parameters shown in the tables here to make the settings for the following: the servomotor stopping

method when the servo is turned OFF, the output signals used to control the dynamic brake contactor, and the

capacity of the dynamic brake resistor in relation to whether or not a dynamic brake has been connected.

The servomotor stopping method when the servo is turned OFF is set with parameter Pn001.0.

When using a dynamic brake resistor from a company other than Yaskawa, set Pn00D.1 (second digit) to 0 or

1 in accordance with the following table depending if an NO or NC contact is used.

The dynamic brake resistor capacity is set with Pn601.

(1) Using a Yaskawa Dynamic Brake Unit

• Set Pn001 to n.

0.

• Not necessary to set Pn00D

• Set Pn601 to 0.

(2) Using a Dynamic Brake Resistors from Another Company

• Set Pn001 to n.

0.

• Set Pn00D to either n.

0D or n.

1

depending on your system.

• Set Pn601 to 20% of the resistor capacity of your dynamic brake.

(3) Not Using a Dynamic Brake

• Set Pn001 to n.

2.

• Not necessary to set Pn00D

• Set Pn601 to 0.

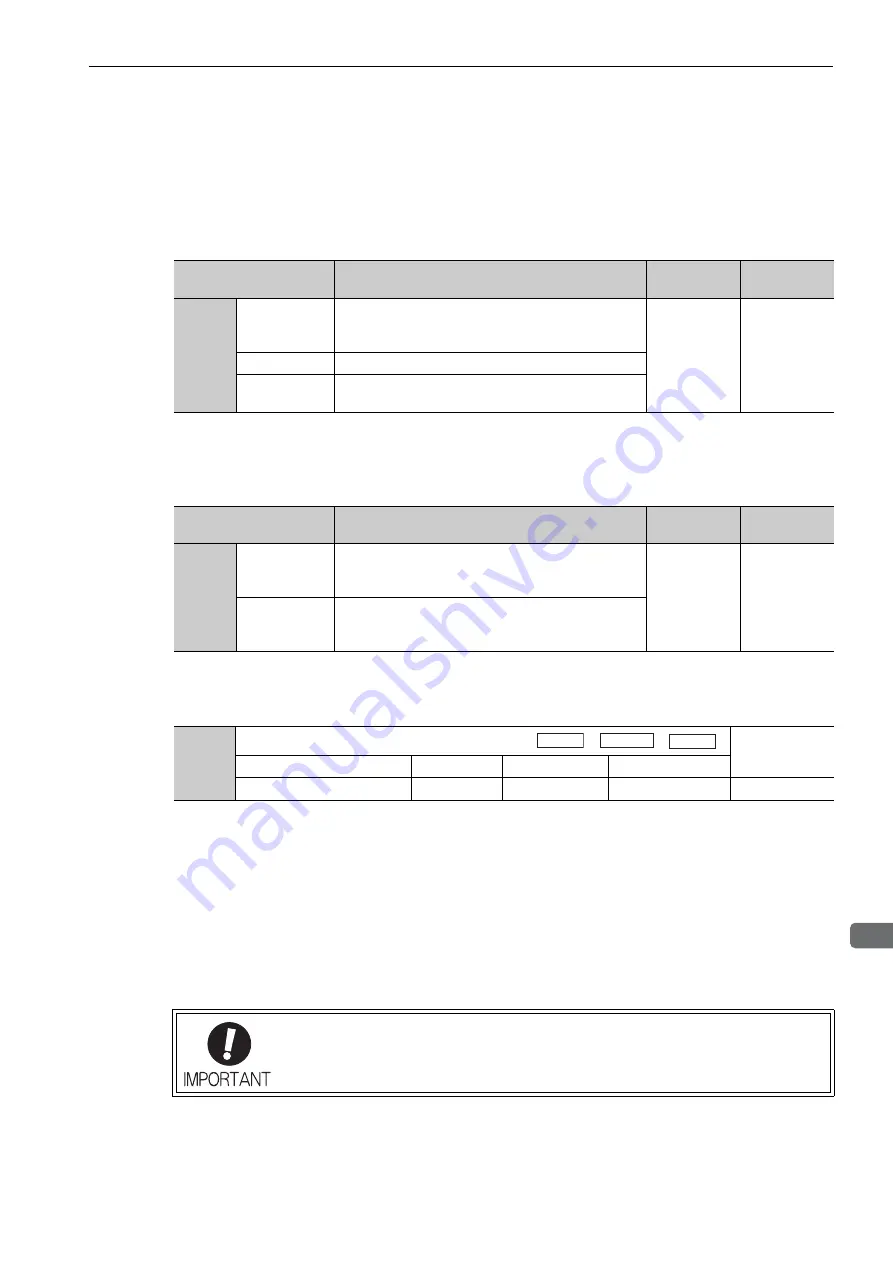

Parameter

Meaning

When

Enabled

Classification

Pn001

n.

0

[Factory

setting]

Stops servomotor by applying DB (dynamic brake).

After restart

Setup

n.

1

Stops servomotor by applying DB and then releases DB.

n.

2

Stops servomotor without applying DB by coasting to a

stop.

Parameter

Meaning

When

Enabled

Classification

Pn00D

n.

0

[Factory

setting]

Enables the control of an NO contactor

(The dynamic brake is activated when current is sup-

plied to the contactor coil.)

After restart

Setup

n.

1

Enables the control of an NC contactor

(The dynamic brake is activated when current is not

supplied to the contactor coil.)

Pn601

Dynamic Brake Resistor Capacity

Classification

Setting Range

Unit

Factory setting

When Enabled

0 to SERVOPACK capacity

10 W

0

After restart

Setup

Speed

Position

Torque

If the setting of Pn601 is not correct, A.730 or A.731 (dynamic brake overloads) will not

be detected correctly and there is a risk of equipment damage or fire. The Pn601 param-

eter is for the multi-winding drive unit. Do not mistakenly change the SERVOPACK

parameter.