3 Wiring and Connection

3.11.1 Wiring for Noise Control

3-42

(1) Noise Filter

The multi-winding drive unit, SERVOPACKs, and converters have built-in microprocessors, so protect them

from external noise as much as possible by installing noise filters in the appropriate places.

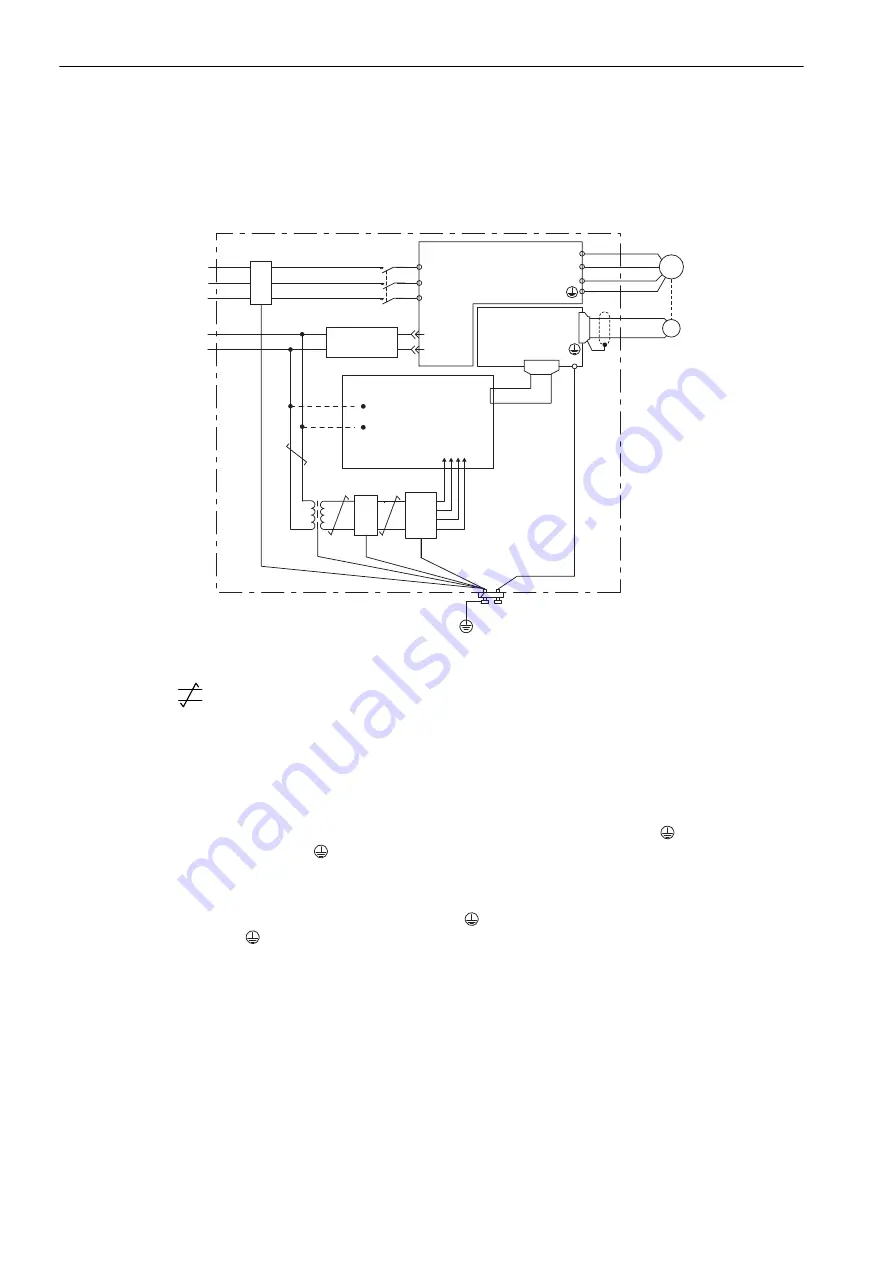

The following is an example of wiring for noise control.

∗1.

For ground wires connected to the ground plate, use a thick wire with a thickness of at least 2.0 mm

2

(preferably,

plain stitch cooper wire).

∗2.

should be twisted-pair wires.

∗3.

When using a noise filter, follow the precautions in

3.11.2 Precautions on Connecting Noise Filter

.

(2) Correct Grounding

Take the following grounding measures to prevent the malfunction due to noise.

Grounding the Motor

Always connect servomotor frame terminal FG to the SERVOPACK ground terminal . Also be sure to

ground the ground terminal .

If the servomotor is grounded via the machine, a switching noise current will flow from the main circuit of the

SERVOPACK and converter through the stray capacitance of the servomotor. To prevent the adverse effects of

switching noise, always connect the ground terminal in the motor terminal box on the servomotor to the

ground terminal on the SERVOPACK.

Noise on the I/O Signal Cable

If the I/O signal cable receives noise, ground the 0 V line (SG) of the I/O signal cable. If the servomotor main

circuit cable is accommodated in a metal conduit, ground the conduit and its junction box. For all grounding,

ground at one point only.

Servomotor

Operating relay sequence

Signal generation circuit

(not included)

DC

power

supply

(Ground plate)

Ground: Ground to an independent ground

2.0 mm

2

min.

400 VAC

100/200 VAC

Noise filter

∗

3

2.0 mm

2

min.

2.0 mm

2

min.

U

W

V

L2

L1

L3

0V

24V

CN101

CN21

CN1

SERVOPACKs and converters

(2 pairs)

Multi-winding drive unit

*1

*3

*2

ENC

(FG)

M

24-VDC

power supply

+

-

Noise

filter