The System SLIO safety DI module can be used with cable length up to 330m (capacity

up to 100nF, ohmic resistance up to 22.4Ω). General rule: A single-channel sensor is suf-

ficient to achieve SIL2/Cat. 3/PLd; to achieve SIL3/Cat.4/PLe, sensors must be con-

nected via two channels.

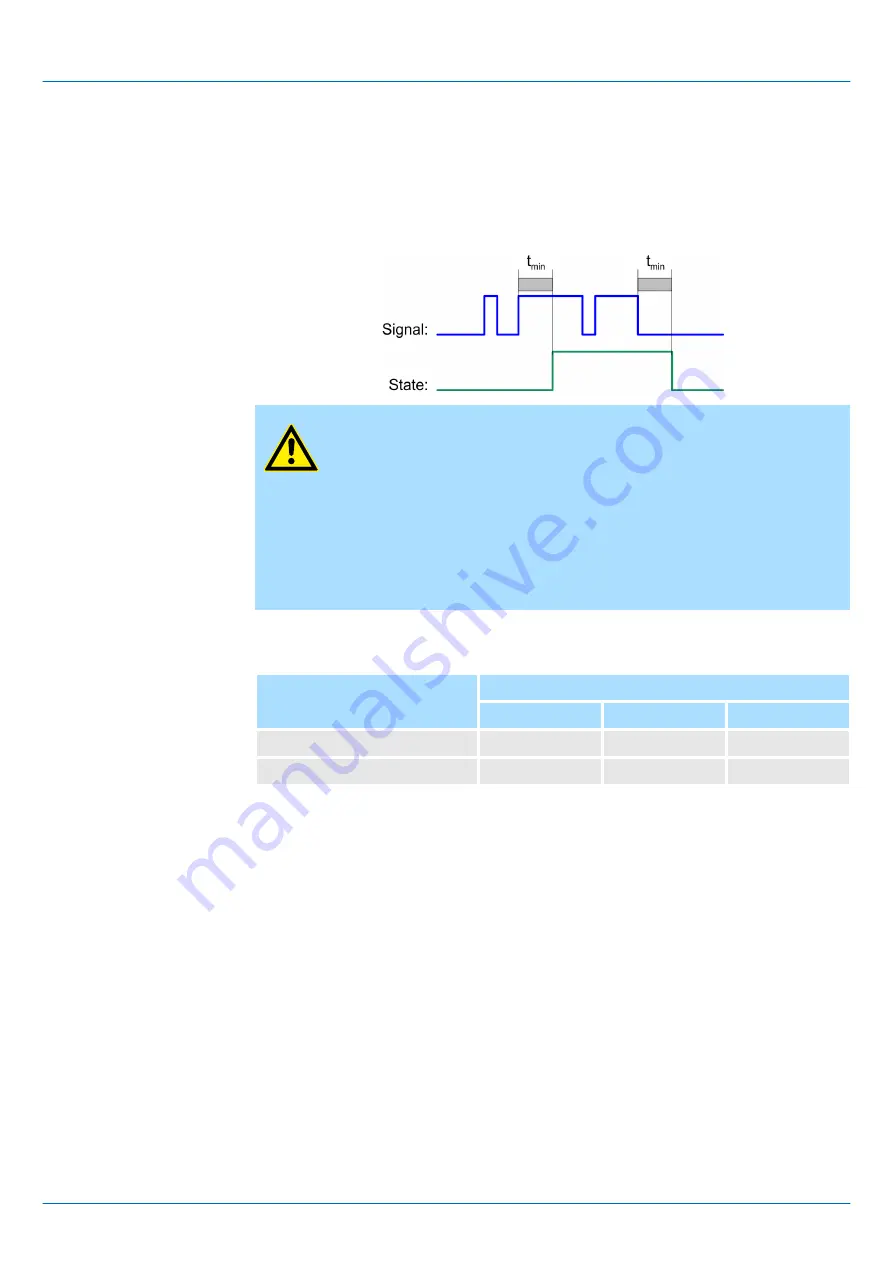

Note the following requirements on the sensor signals:

CAUTION!

In order to guarantee accurate detection of sensor signals by the safety

DI module, you must ensure that the sensor signals have a defined

min-

imum duration

.

The

minimum duration

is a minimum switch-on and switch-off duration,

which is necessary to detect a signal in the worst case. The time interval

between two signal transitions must be greater than the Sync Manager

monitoring time (SM Watchdog) for EtherCAT communication to allow

reliable detection of the pulses. This must be specified in the

SPEED7

EtherCAT Manager

within the parameters for the slave station.

Reliable detection by the safety DI module

Parameter short-circuit test

Parametrized input delay

1ms

3ms

15ms

de-activated

7ms

9ms

23ms

activated

8ms

12ms

37ms

In the table exemplary the minimum duration of the sensor signals of the safety DI

module is shown. It depends on the configuration of the short-circuit test and the input

delay in the Configuration tool of the FSoE master.

Requirements to the sen-

sors

Duration of the sensor sig-

nals

VIPA System SLIO

Deployment

Wiring > Requirements to the sensor and actuators

HB300 | SM-S | 02x-1SD10 | en | 20-02

89