4.

Control parameter setting

4.1.

Boot information

full screen >>> XMTN

(

N shows the quantity of zones

)

>>> V3.00

(

Software version

number

)

>>> normal condition

4.2.

CHANNEL SELECT

After long press or for one second, the current loop number starts flashing, and then

short press or to switch the control loop. The N+1 channel is the temperature display

of the environment (cold end of thermocouple).

4.3.

Control parameter setting

Long press for 3 seconds to enter the setting state of control parameters. At this time,

the upper row displays parameter prompt SV, and the lower row displays control parameters.

At this point, the single digit flashes, short press and move the flshing digits. After

selecting the number of digits to be modified, short press or to modify the control

parameter. Continue to press , and display each parameter prompt in the upper row. After

finding the parameter that needs to be modified, continue to press to move the flshing

digits. After selecting the number that needs to be modified, press or again to modify

the control parameter.

Long press for more than 1 second, the controller automatically returns to the normal

control state (no button operation within 60 seconds, the controller automatically returns to the

normal control state).

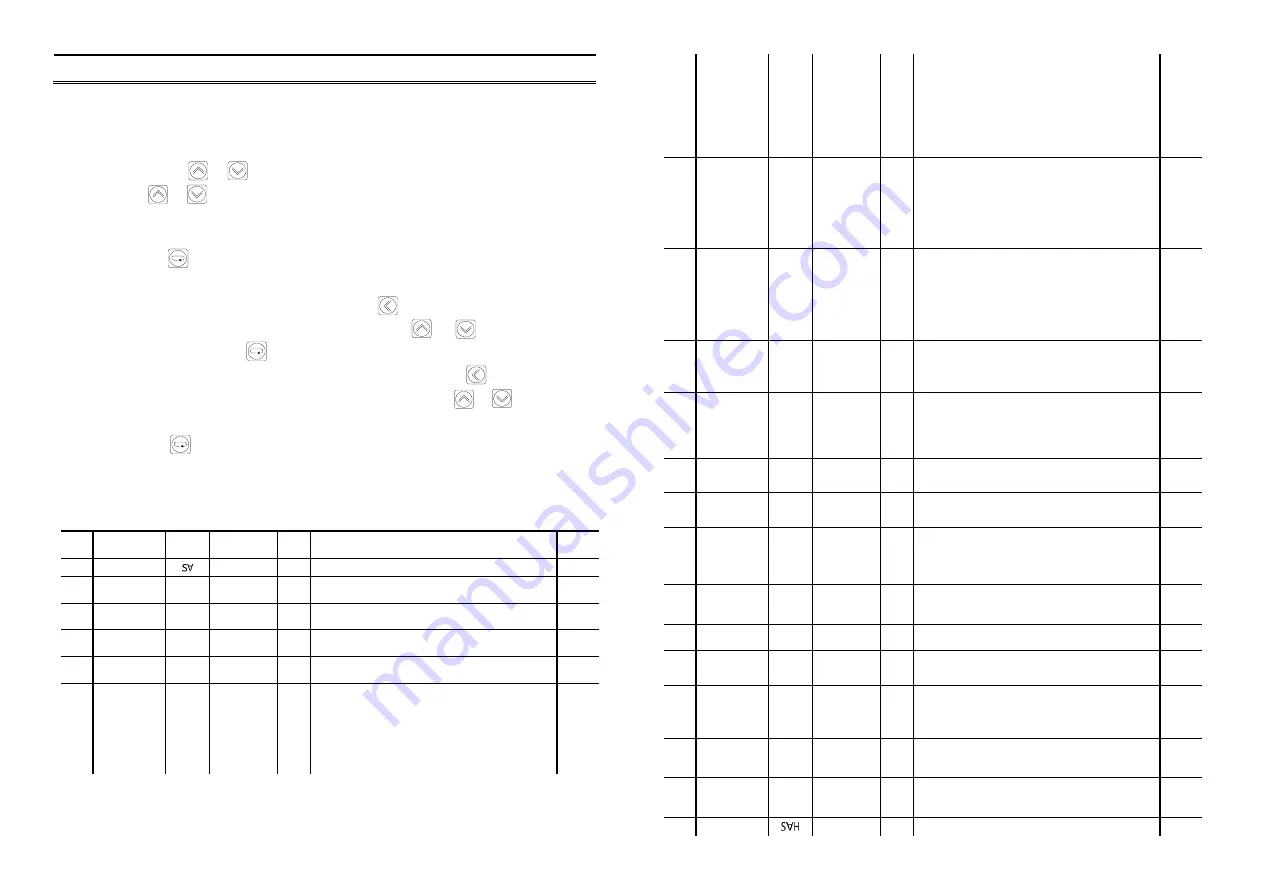

4.4.

A list of control parameter Settings

No.

Parameter

Name

Symbol Data Range Unit

Introductions

Initial

value

1

Set value

SVL

~

SVH

℃

The set target value of the zone of the controller

100

2

The lower

limit alarm 1

AL1

-500

~

4000

℃

See 4.5, alarm output instructions for details

50

3

The lower

limit alarm 2

AL2

-500

~

4000

℃

Same as AL1, but can only be output through

communication

50

4

Upper limit

alarm 1

AH1

-500

~

4000

℃

See 4.5, alarm output instructions for details

50

5

Upper limit

alarm 2

AH2

-500

~

4000

℃

Same as AH1, but can only be output through

communication

50

6

Alarm type

SA

00

~

66

—

The single digit of XX is type 1 of alarm, while the

ten digit is type 2 of alarm. X=0: no alarm; 1: upper

limit deviation alarm; 2: lower limit deviation alarm;

3: alarm outside the deviation value of upper and

lower limits; 4: alarm within the deviation value of

upper and lower limits; 5: upper absolute value

alarm;

01

7

Positive and

negative

action control

and first

power on

alarm enable

EA

000

~

111

—

The hundred digits of XXX are positive and

negative control options: X=0: reaction control

(heating type); 1: positive action control (cooling

type). The ten digit of XXX is first choice of alarm

2, the single digit of XXX is first choice of alarm 1:

X=0: After the power on the alarm condition does

not alarm, then all alarm if the alarm condition is

met; 1: all alarm if the alarm condition is met.

011

8

Proportional

band

P

0

~

9999

℃

Regulation of proportional action: the larger the P,

the smaller the proportional action, the lower the

system gain. 0: change to on-off control mode. At

this point, the integral time I becomes 0.1 times of

the upper limit of the insensitive region and the

differential time D becomes 0.1 times of the lower

limit of the insensitive region.

30

9

Integral time

I

0

~

9999

Sec.

Integral action time constant: the larger the I, the

weaker the integral action, mainly used to eliminate

the static difference. 0: become a PD control

method, the integral inhibit Ar to set (RESET), and

the Ar is set to zero, the unit for

, is used to

℃

eliminate static error. When P=0, see the description

of P.

240

10

Differential

Time

d

0

~

9999

Sec.

Differential action time constant: the larger the D,

the stronger the differential action, which is mainly

used to restrain the overshoot of measured values.

When P=0, see the description of P.

60

11

Restrained

Integration

Ar

0

~

100

%

Restrained Integration ratio: the larger the Ar, the

larger the overthrust, and the smaller the Ar, the

possible static difference.

When the integral time I is equal to 0, see the

description of the integral time I

100

12

Control cycle

t

1

~

100

Sec.

Output of thyristor or solid-state relay: 2~3 seconds;

Relay output: 20~30 seconds

3

13

Sensor error

correction

Pb

-500

~

4000

℃

Used to correct measurement error caused by sensor

and thermocouple compensation wire

0.0

14

Auto tuning

At

n

O or YES

—

YES: start self-tuning and restore nO after

self-tuning. If the self-tuning rule is not completed

within 4 hours, the original P, I and D values are still

used for control.

n

O

15

Auto tuning

Limit

AtU

0

~

100

%

In order to overcome the overshoot phenomenon of

the Auto tuning time, the Auto tuning control point

can be lowered to SV x ATU.

100

16

Graduation

S

n

0

~

18

—

See 1.2 list of commonly used input types and range

for details.

3-K

17

Decimal

point

dP

0

~

1

—

0

:

the resolution of the measured values PV 1

℃

;

1

:

the resolution of the measured values PV 0.1

℃

0

18

Filter

coefficients

FILt

0

~

250

—

The smaller this value, the faster the measured value

responds, but there may be fluctuations; The larger

this value, the slower the measured value response

and the more stable the display.

125

19

Screen

blanking

dt

0

~

250

℃

Used to suppress the change sensitivity of the

display value, and the range of inhibition is 0.1

times of the display inhibition dt.

15

20

Alarm1

differential

gap

FH1

-500

~

4000

℃

The differential gap is 0.1 times of FH1

4

21

Upper limit

-500

~

4000

℃

The highest measured value is SVH

300