16

O R I G I N A L I N S T R U C T I O N S

Other maintenance activities

Before each use of the tool make sure there are no signs of any damage to the tool. The drivers, grips and spindles must be maintained clean.

Every six months or after 100 hours of operation the tool must be inspected by a quali

fi

ed repair shop. If the tool is used without the recommended air supply system, then

the frequency of such inspections must be increased.

Elimination of problems

Should any failure be detected, the operation of the tool must be interrupted immediately. Work with a defective tool may be a cause of injuries. Any repair or replacement

of the elements of the tool must be realised in a quali

fi

ed repair shop.

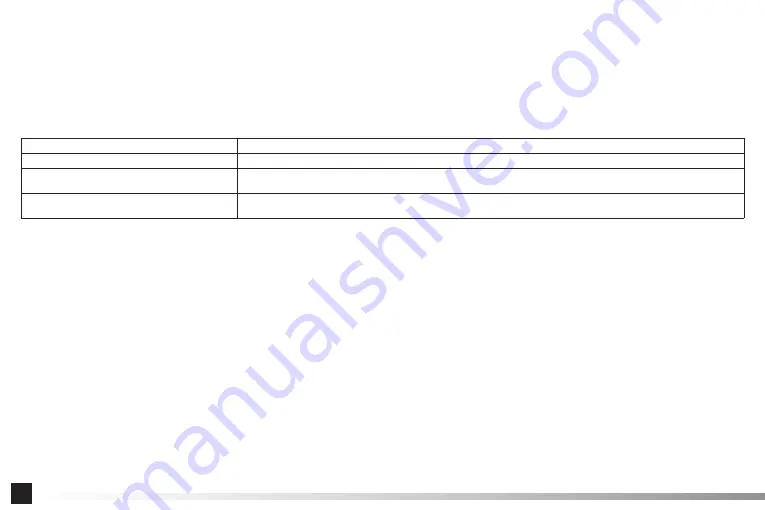

Defect

Possible solution

The air is blown between the lead and the casing of the tool

Check if the screws are not loose. Check the condition of the sealing

The tool does not start or is too slow

The compressor does not provide a suf

fi

cient air supply. Connect the device to a more ef

fi

cient compressor. Insuf

fi

cient lubrication. Check the condition of

the sealing

Insuf

fi

cient power

Make sure the internal diameter of the hoses complies with the required value from the table. Check whether the pressure is set to the acceptable maximum

value. Make sure the tool is properly cleaned and lubricated. If the problem persists, have the tool repaired.

Summary of Contents for YT-0925

Page 24: ...24...

Page 25: ...25...

Page 26: ...26 10 CEN CENELEC...

Page 27: ...27 4 5 SAE 30W...

Page 28: ...28 II IV 13 8 V 0 05 0 05 6 100...

Page 29: ...29...

Page 31: ...31 K...

Page 32: ...32...

Page 33: ...33 10 CEN CENELEC...

Page 34: ...34 4 5 SAE 30W II IV 13 8...

Page 35: ...35 V 0 05 0 05 6 100...

Page 78: ...78 I N S T R U K C J A O R Y G I N A L N A...