10

O R I G I N A L I N S T R U C T I O N S

GB

CHARACTERISTICS OF THE TOOL

Pneumatic wrench is a tool that is powered with a stream of compressed air at appropriate pressure. Wrenches installed on a

collector make screwing down and unscrewing possible, particularly where a high turning moment is required. The tool is not

supposed to function in a continuous manner. Correct, reliable and safe functioning of the tool depends on correct operation,

therefore:

Before operation of the tool can be commenced, the whole manual must be read and kept.

The supplier cannot be held responsible for any damages or injuries which are caused by using the tool in a manner that does not

correspond to its purpose, not observing safety regulations or the recommendations of the present instructions. Using the tool in

a manner that does not correspond to its purpose also cancels the guarantee.

EQUIPMENT

The pneumatic wrench is equipped with a connector that facilitates its connection to the pneumatic system.

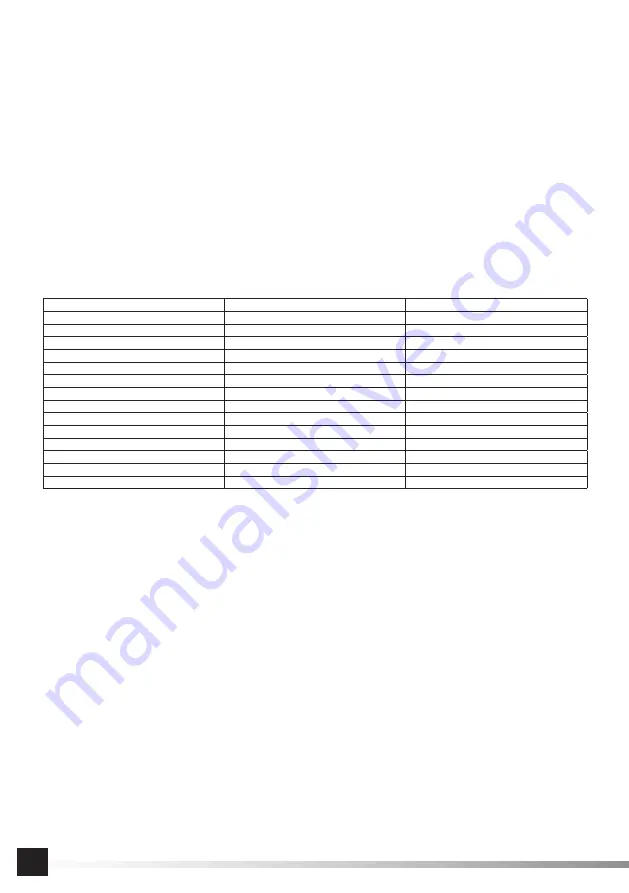

TECHNICAL DATA

Parameter

Measurement unit

Value

Catalogue number

YT-09564

Length

[mm]

230

Weight

[kg]

4,7

Diameter of the air connection (PT)

[mm / ”]

10 / 3/8

Inside diameter of the air supply hose

[mm / ”]

10 / 3/8

Rotations [min

-1

]

5000

Maximum turning moment

[Nm]

1300

Size of the collector

[mm / ”]

19 / 3/4

Maximum working pressure

[MPa]

0,6 – 0,8

Recommended working pressure

[MPa]

0,63

Required air

fl

ow (at 6.3 bar)

[l/min]

660

Acoustic pressure LpA (ISO 15744)

[dB(A)]

92 ± 3

Acoustic power LwA (ISO 15744)

[dB(A)]

103 ± 3

Vibrations (ISO 28927-2)

[m/s

2

]

5,47 ± 1,5

GENERAL SAFETY CONDITIONS

WARNING! During operation of a pneumatic tool, it is recommended to always observe the basic safety regulations including

those mentioned below, in order to diminish the risk of

fi

re, electric shock and injury.

Before operation of the tool can be commenced, the whole manual must be read and kept.

ATTENTION!

Read all the instructions mentioned below. If they are not observed, there is a risk of electric shock,

fi

re or injury.

The notion of „pneumatic tool” that is used in the instructions refers to all tools that are powered with a stream of compressed air

at appropriate pressure.

OBSERVE THE FOLLOWING INSTRUCTIONS

General safety rules

For multiple hazards, read and understand the safety instructions before installing, operating, repairing, maintaining, changing acces-

sories on, or working near the assembly power tool for threaded fasteners. Failure to do so can result in serious bodily injury. Only

quali

fi

ed and trained operators should install, adjust or use the assembly power tool for threaded fasteners. Do not modify this as-

sembly power tool for threaded fasteners. Modi

fi

cations can reduce the e

ff

ectiveness of safety measures and increase the risks to the

operator. Do not discard the safety instructions; give them to the operator. Do not use the assembly power tool for threaded fasteners if

it has been damaged. Tools shall be inspected periodically to verify that the ratings and markings required by this part of ISO 11148 are

legibly marked on the tool. The employer/user shall contact the manufacturer to obtain replacement marking labels when necessary.

Projectile hazards

Failure of the workpiece, of accessories or even of the inserted tool itself can generate high-velocity projectiles. Always wear

impact-resistant eye protection during the operation of the assembly power tool for threaded fasteners. The grade of protection

required should be assessed for each use. Ensure that the workpiece is securely

fi

xed.

Summary of Contents for YT-09564

Page 20: ...20 RUS 4 10 60...

Page 21: ...21 RUS...

Page 22: ...22 RUS SAE 10 II F R 1 2 1 38MPa III F R V IV WD 40 30...

Page 23: ...23 RUS SAE 10 SAE 10 WD 40 6 100 WD 40 30 1 2 0 3 MPa...

Page 25: ...25 UA 4 10 60...

Page 26: ...26 UA...

Page 27: ...27 UA SAE 10 II F R 1 2 1 38MPa III F R V IV WD 40 30 SAE 10 SAE 10 WD 40 6 100...

Page 28: ...28 UA WD 40 30 1 2 0 3 MPa...

Page 76: ...76 GR 4 Nm 10 Nm 60 Nm...

Page 77: ...77 GR...

Page 78: ...78 GR VII SAE 10 II V 1 2 1 38 MPa III V II WD 40 30 SAE 10 SAE 10 WD 40...

Page 79: ...79 GR 6 100 WD 40 30 3...