11

GB

O R I G I N A L I N S T R U C T I O N S

CHARACTERISTIC OF THE TOOL

The pneumatic eccentric grinder is a tool which uses compressed air

under appropriate pressure to operate. The grinding blade is equipped

with a Velcro-type fastener that allows the attachment of paper or abra-

sive cloth discs of diff erent grain sizes and applications. The grinder

is mainly used in painting works related to preparation of surfaces for

subsequent stages of varnishing. Proper, reliable and safe operation of

the tool depends on appropriate use, that is why you should:

read and keep the entire instruction manual before the fi rst use

of the tool.

The supplier shall not be held liable for any damage or injury resulting

from improper use of the tool, failure to observe the safety regulations

and recommendations of this manual. Use of the tool for purposes

other than those for which it was intended shall cause the loss of the

user’s rights to the warranty, as well as under inconsistencies with

the agreement.

ACCESSORIES

The grinder is equipped with a connector to connect to the pneumatic

system. The grinder is fi tted with 50 mm diameter wheel.

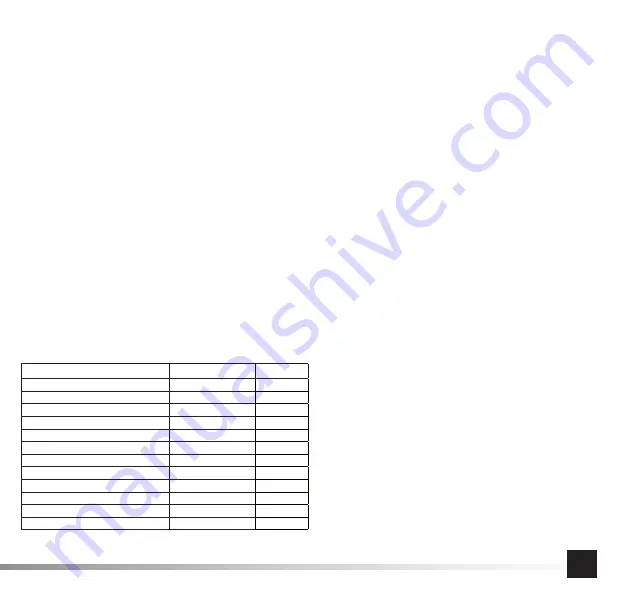

TECHNICAL DATA

Parameter

Unit

Value

Catalog number

YT-09730

Weight

[kg]

0,65

The diameter of air connection (PT)

[mm]

6,3 / 1/4

The diameter of air supply hose (internal)

[” / mm]

10 / 3/8

Revs

[min

-1

]

20 000

The diameter of tool handle

[mm]

M6

Diameter of the disk

[mm]

50

Maximum operation pressure

[MPa]

0,63

Required air fl ow (at 0,63 MPa)

[l/min]

113

Acustic pressure (EN ISO 15744)

[dB(A)]

87 ± 3

Acustic power (EN ISO 15744)

[dB(A)]

98 ± 3

Vibrations (ISO 28927-3)

[m/s

2

]

2,3 ± 2,5

GENERAL SAFETY CONDITIONS

WARNING! During the tool operation you should always adhere to the

fundamental principles of security including the following guidelines,

in order to reduce the risk of fi re, electric shock, and avoid injuries.

Before proceeding to the use of this tool you should read the

whole instruction and keep it.

ATTENTION! Read all the following guidelines. Failure to comply with

them may lead to electric shock, fi re, or damage to the body. The

concept of a

“pneumatic tool

”, which is used in the instructions refers

to all tools driven by compressed air stream under proper pressure.

FOLLOW THE GUIDELINES BELOW

General safety rules

Prior to installation, operation, repair, maintenance and modifi cation

of accessories or, in the case of work near pneumatic tool, because

of the many risks, you should read and understand the safety in-

structions. Lack of implementation of these activities can result in

serious injury. Installation, regulation and assembly of pneumatic

tools can be performed only by qualifi ed and trained personnel. Do

not modify the pneumatic tool. Modifi cations may reduce its effi cien-

cy and safety level and increase the risk for the tool operator. Do

not throw away the safety instructions, they must be passed to the

tool operator. Do not use the pneumatic tool, if it is damaged. The

tool should be periodically inspected for visibility of data, which is

required by the standard ISO 11148. The employer / user should

contact the manufacturer in order to exchange plate every time

when it is necessary.

The risks associated with entanglement

The risks associated with entanglement may cause choking, scalp-

ing and / or injury when loose clothing, jewelry, hair or gloves are not

kept away from tool and accessories.

The risks associated with work

The use of tool can put hands operator risks, such as: crushing, im-

pact, cutting, abrasion and heat. You should wear appropriate gloves

to protect your hands. The operator and maintenance staff should

be able to cope physically with the quantity, weight, and power tool.

Summary of Contents for YT-09730

Page 23: ...23 RUS...

Page 24: ...24 RUS...

Page 25: ...25 RUS II IV V SAE 10...

Page 26: ...26 RUS 10 3 8 1 38 VI...

Page 27: ...27 RUS WD 40 30 SAE 10 SAE 10 WD 40 6 100 WD 40 30 10 3 8 0 3 MPa...

Page 29: ...29 UA...

Page 30: ...30 UA 10...

Page 31: ...31 UA II IV V...

Page 32: ...32 UA SAE 10 10 3 8 1 38 VI...

Page 33: ...33 UA WD 40 30 SAE 10 SAE 10 WD 40 6 100 WD 40 30 10 3 8 0 3 MPa...

Page 89: ...89 GR...

Page 90: ...90 GR...

Page 91: ...91 GR IV V SAE 10 10 mm 3 8 1 38 MPa V...

Page 92: ...92 GR VI 0 WD 40...

Page 93: ...93 GR 30 SAE 10 SAE 10 WD 40 6 100 WD 40 30 3 TOYA SA www toya pl 0 3 MPa...