11

O R I G I N A L I N S T R U C T I O N S

GB

PROPERTIES OF THE TOOL

The pneumatic belt grinder is a tool powered with compressed air under adequate pressure. Thanks to the endless grinding belts

it is possible to grind and polish different surfaces. The tool has been designed for work in interiors and it must not be exposed to

humidity and precipitations. A correct reliable and safe functioning of the tool depends on its operation, so:

Before any work with the tool, it is required to get acquainted with the manual and keep it.

The supplier will not be held responsible for any damage and injuries caused by operating the tool for purposes it has not been

designed for, inobservance of the safety regulations and the recommendations included in this manual. Furthermore operating

the tool for purposes it has not been designed for cancels any guarantee rights of the user and any rights as regards inconformity

with the contract.

ACCESSORIES

The grinder is equipped with a connector which permits to connect it to a pneumatic system. The grinder is equipped with three

endless grinding belt of different granularity.

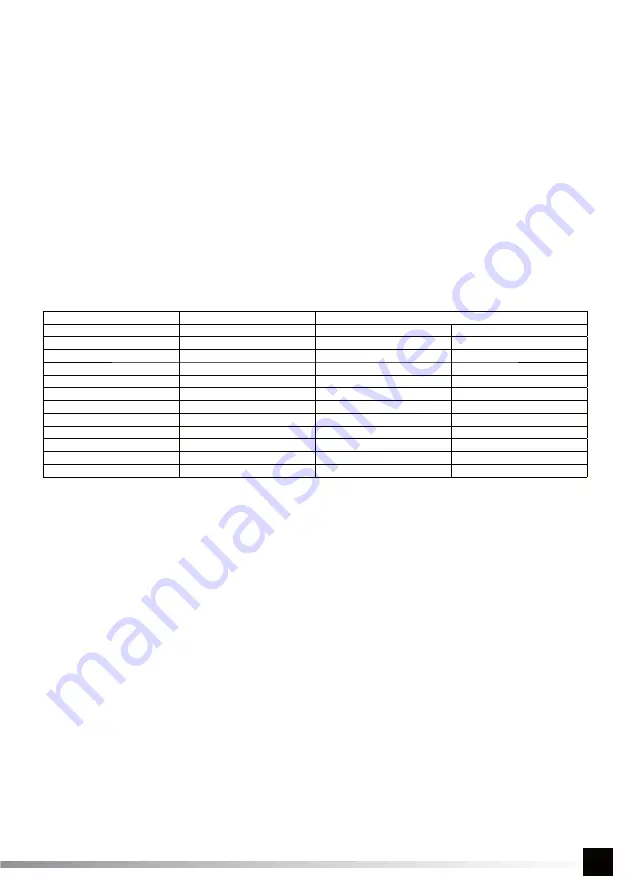

TECHNICAL DATA

Parameter

Unit of measurement

Value

Catalogue number

YT-09741

YT-09742

Weight [kg]

0,78

1,10

Diameter of the air connector (PT)

[mm / ”]

6,3 / 1/4

6,3 / 1/4

Internal diameter of the air supply hose

[mm / ”]

10/ 3/8

10/ 3/8

Nominal rotation

[min

-1

]

20 000

20 000

Size of the grinding belt

[mm]

10 x 330

20 x 520

Maximum operating pressure

[MPa]

0,63

0,63

Recommended operating pressure

[MPa]

0,6

0,6

Required air flow (at 6.2 bars)

[l/min]

170

200

Acoustic pressure (ISO 15744)

[dB(A)]

93 ± 3

93 ± 3

Acoustic power (ISO 15744)

[dB(A)]

104 ± 3

104 ± 3

Vibration (ISO 28927-3)

[m/s

2

]

4,8 ± 1,5

4,8 ± 1,5

GENERAL SAFETY RULES

General safety rules

For multiple hazards, read and understand the safety instructions before installing, operating, repairing, maintaining, changing

accessories on, or working near the assembly power tool for threaded fasteners. Failure to do so can result in serious bodily injury.

Only qualified and trained operators should install, adjust or use the assembly power tool for threaded fasteners. Do not modify

this assembly power tool for threaded fasteners. Modifications can reduce the effectiveness of safety measures and increase the

risks to the operator. Do not discard the safety instructions; give them to the operator. Do not use the assembly power tool for

threaded fasteners if it has been damaged. Tools shall be inspected periodically to verify that the ratings and markings required

by this part of ISO 11148 are legibly marked on the tool. The employer/user shall contact the manufacturer to obtain replacement

marking labels when necessary.

Projectile hazards

Be aware that failure of the workpiece or accessories, or even of the inserted tool itself can generate high-velocity projectiles.

Always wear impact-resistant eye protection during operation of the sander or polisher. The grade of protection required should

be assessed for each use. For overhead work, wear a safety helmet. The risks to others should also be assessed at this time.

Ensure that the workpiece is securely fixed.

Entanglement hazards

Choking, scalping and/or lacerations can occur if loose clothing, personal jewellery, neck wear, hair or gloves are not kept away

from the tool and its accessories.

Operating hazards

Use of the tool can expose the operator’s hands to hazards, including cuts and abrasions and heat. Wear suitable gloves to protect

hands. Operators and maintenance personnel shall be physically able to handle the bulk, weight and power of the tool. Hold the

tool correctly; be ready to counteract normal or sudden movements and have both hands available. Maintain a balanced body po-

sition and secure footing. Release the start-and-stop device in the case of an interruption of the energy supply. Use only lubricants

Summary of Contents for YT-09741

Page 21: ...21 RUS...

Page 22: ...22 RUS...

Page 23: ...23 RUS SAE 10 II 10 3 8 1 38 III IV V VI VII WD 40 30 SAE 10 SAE 10 WD 40...

Page 24: ...24 RUS 6 100 WD 40 30 0 3...

Page 26: ...26 UA...

Page 27: ...27 UA SAE 10 II 10 3 8...

Page 28: ...28 UA 1 38 III IV V VI VII WD 40 30 SAE 10 SAE 10 WD 40 6 100...

Page 29: ...29 UA WD 40 30 0 3...