14

O R I G I N A L I N S T R U C T I O N S

GB

the same time move it perpendicularly to the direction of rotation. This might cause the band to fall from the z rollers of the grinder,

which in turn implies a risk of serious injuries.

MAINTENANCE

Do not ever use gasoline, solvents or any other inflammable liquids to clean the tool. Vapours may ignite causing explosion of the

tool and serious injuries.

Solvents used to use the handle and the body of the tool may soften the sealing. Dry the tool thoroughly before work com-

mences.

In case any irregularities in the functioning of the tool are detected, the tool must be immediately disconnected from the pneumatic

system.

All the elements of the pneumatic system must be protected from dirt. Dirt inside the pneumatic system may damage the tool and

other elements of the pneumatic system.

Maintenance of the tool before each use

Disconnect the tool from the pneumatic system.

Before each use place a small quantity of maintenance liquid (eg. WD-40) into the air inlet.

Connect the tool to the pneumatic system and start it for about 30 seconds. This will permit to distribute the maintenance liquid

inside the tool and clean it.

Disconnect the tool from the pneumatic system.

Place a small quantity of a SAE 10 oil inside the tool through the air inlet and holes provided for this purpose. It is recommended

to use a SAE 10 oil for maintenance of pneumatic tools. Connect the tool and start it for a while.

Attention! A WD-40 oil must not be used as the proper lubricant.

Wipe off the excess of oil which comes out of the outlets. Remaining oil might damage the sealing of the tool.

Other maintenance tasks

Before each use of the tool make sure there is no visible damage of the tool. Drivers, fixtures and spindles must be kept clean.

Every six months, or after 100 hours of operation, have the tool revised by qualified personnel in a service workshop. If the tool

was used without the recommended air supply system, the frequency of inspections must be increased.

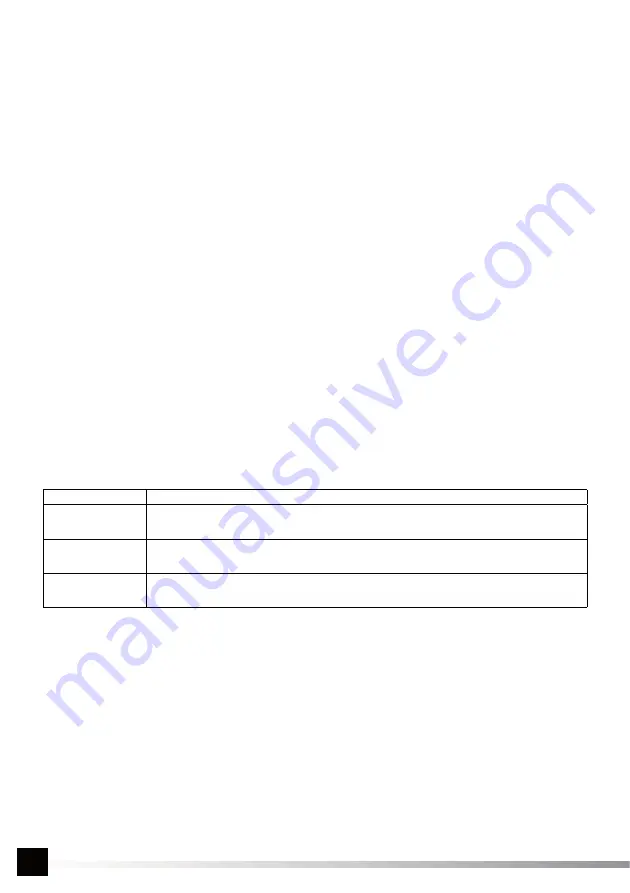

Trouble shooting

Stop using the tool immediately, if any damage is detected. Working with a non-operational tool may cause injuries. Any repairs

and replacement of the elements of the tool must be realised by qualified personnel in a service workshop.

Failure Possible

solution

The rotation of the tool is too

low or the tool does not start

Place a small quantity of a WD-40 grease in the air inlet. Start the tool for a couple of seconds. The blades might have stuck to the rotor.

Start the tool for about 30 seconds. Lubricate the tool with a small quantity of oil. Attention! Excess of oil may cause a reduction of the

power of the tool. In such cases the power transmission system must be cleaned.

The tool starts and then

slows down

The compressor does not ensure a sufficient air supply. The tool starts thanks to the air accumulated in the compressor tank. When the

tank is being emptied, the compressor does not follow up. Connect the device to a more efficient compressor.

Insufficient power

Make sure the internal diameter of the hoses is at least the once indicated in the technical specification. Check whether pressure is set

to the maximum value. Make sure the tool is properly cleaned and lubricated. If there are no results have the tool repaired.

Spare parts

Information regarding spare parts for pneumatic tools may be obtained from the manufacturer or their agent.

Once work has been concluded, the casing, the ventilation orifices, the switches, the additional handle and the guards must be

cleaned, e.g. with air jet (whose pressure must not exceed 0.3 MPa), with a brush or with a dry cloth, without using any chemicals

or cleaning liquids. The tool and the handles should be cleaned with a dry and clean cloth.

Old tools are recyclable – they must not be disposed of with household garbage, since they contain substances which are danger-

ous for people and the environment! We ask for active assistance in efficient management of natural resources and protection

of the environment. Send the device to an adequate collection point. In order to reduce the amount of waste, it is necessary to

reuse, recycle or recover it.

Summary of Contents for YT-09741

Page 21: ...21 RUS...

Page 22: ...22 RUS...

Page 23: ...23 RUS SAE 10 II 10 3 8 1 38 III IV V VI VII WD 40 30 SAE 10 SAE 10 WD 40...

Page 24: ...24 RUS 6 100 WD 40 30 0 3...

Page 26: ...26 UA...

Page 27: ...27 UA SAE 10 II 10 3 8...

Page 28: ...28 UA 1 38 III IV V VI VII WD 40 30 SAE 10 SAE 10 WD 40 6 100...

Page 29: ...29 UA WD 40 30 0 3...