Serial

Nmber

I

TEM NO.

Name

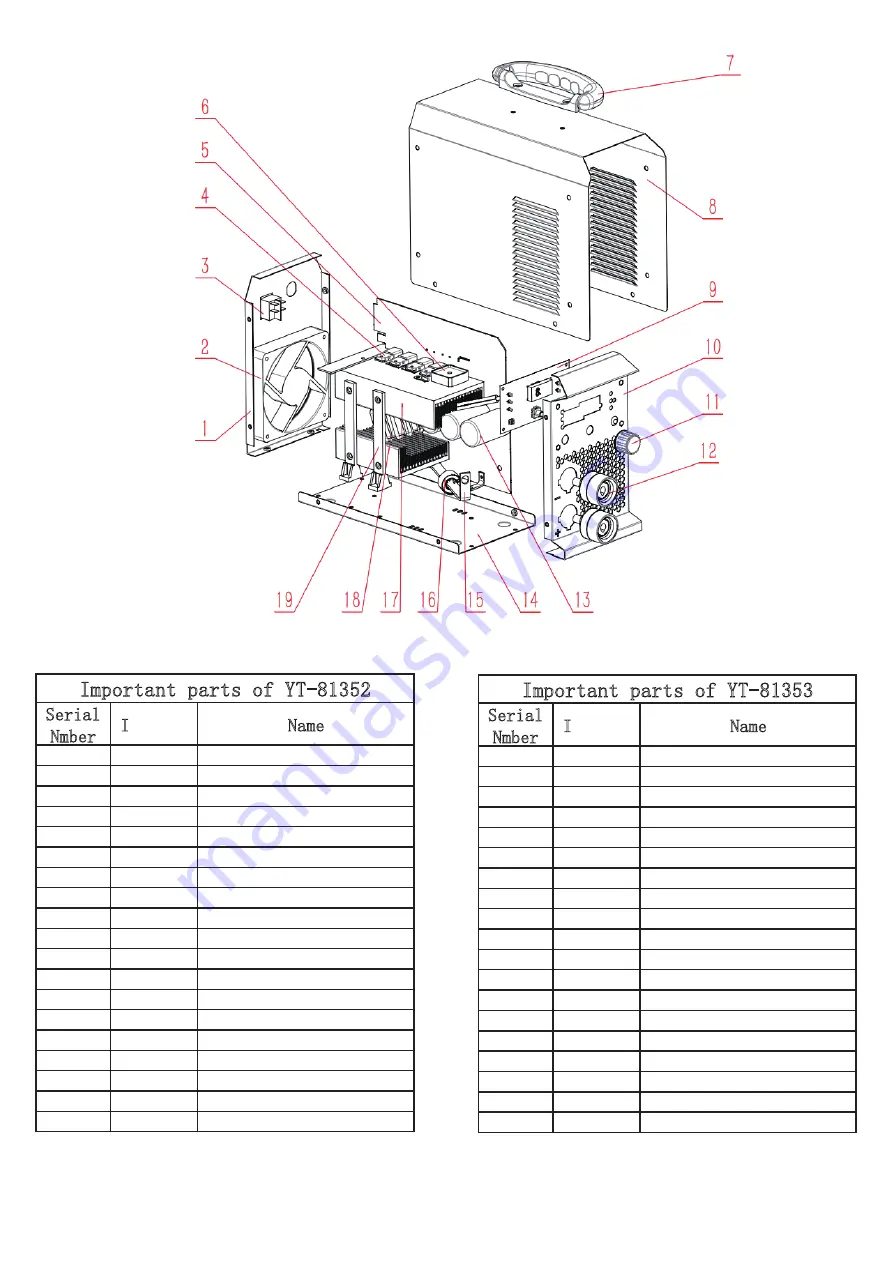

1

ZY8135201

Metal back panel

2

ZY8135202

Fan

3

ZY8135203

Switch

4

ZY8135204

IGBT

5

ZY8135205

Main PCB

6

ZY8135206

Retifier bridge

7

ZY8135207

Plastic handle

8

ZY8135208

Metal cover

9

ZY8135209

Front PCB

10

ZY8135210

Metal front panel

11

ZY8135211

Knob

12

ZY8135212

Quick Plug Socket

13

ZY8135213

Capacitor

14

ZY8135214

Metal base plate

15

ZY8135215

Aluminum connection bar

16

ZY8135216

Current Hall

17

ZY8135217

Aluminum Radiator

18

ZY8135218

Transformer

19

ZY8135219

Plastic support strip

Important parts of YT-81352

Serial

Nmber

I

TEM NO.

Name

1

ZY8135301

Metal back panel

2

ZY8135302

Fan

3

ZY8135303

Switch

4

ZY8135304

IGBT

5

ZY8135305

Main PCB

6

ZY8135306

Retifier bridge

7

ZY8135307

Plastic handle

8

ZY8135308

Metal cover

9

ZY8135309

Front PCB

10

ZY8135310

Metal front panel

11

ZY8135311

Knob

12

ZY8135312

Quick Plug Socket

13

ZY8135313

Capacitor

14

ZY8135314

Metal base plate

15

ZY8135315

Aluminum connection bar

16

ZY8135316

Current Hall

17

ZY8135317

Aluminum Radiator

18

ZY8135318

Transformer

19

ZY8135319

Plastic support strip

Important parts of YT-81353

21

Summary of Contents for YT-81352

Page 21: ...5 3 Electrical principle drawing YT 81352 19...

Page 22: ...YT 81353 20...