17

GB

O R I G I N A L I N S T R U C T I O N S

working. Always wear safety goggles and dust masks, this will protect the eyes, face and respiratory system against dust, exhaust,

and sprayed chemical agent. Always wear appropriate, fitting to the body, protective clothing. Wear gloves, ear protection, and

safety shoes.

As the sprayer is used to spray chemicals, you must carefully read and comply with the instructions supplied by the manufacturer

of agent. Make sure that the given agent is designed to be sprayed with the sprayer. When using chemicals of different types,

before changing the type of chemical, you should carefully empty the tank and installation of a previous chemical. It is important

to follow the instructions that come with the manufacturer of the chemical. Before starting operation of the sprayer as a blower you

should ensure that the chemical agent does not remain in the tank, in supply system for the nozzle, and in the air duct.

Prior to starting the sprayer operation you should designate a protection zone around the work area with a radius of at least 15

meters away from the sprayer. During the work you should pay attention to the wind direction. Operate sprayer in such a manner

that the sprayed agent would not access in the direction of the operator. During the work you should not smoke nor eat. Do not

store chemicals in the same place as food.

Do not aim the sprayer nozzle nor outlet of air hose towards people or animals.

During transport of the sprayer you should make sure that it is turned off. Sprayers should be transported by moving the handles,

which are designed for that purpose. Always wear the sprayer harness as indicated in the manual. Do not carry the sprayer using

only a single sling.

Use only genuine spare parts. Usage of spare parts, which are original, can increase the risk of failure and lead to injury. Sprayers

should be repaired only in authorized services. Use original spare parts. This will minimize the risk of accidents and damage to

equipment.

Sprayers should be stored in a dry, closed room with good ventilation. When storing the sprayer for a long time, you should empty

the fuel tanks and fertilizer. Sprayers should be a subject of maintenance treatment as it is described in the manual.

SPRAYER OPERATION

Installation for spraying chemical an agent in the liquid form

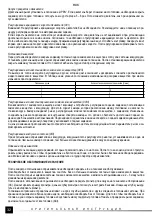

In order to use the device as a sprayer, you should remove the tank for a chemical agent. To do this, please remove the two nuts

securing the tank (II). Then install the sprayer cover (III) and connect the entire system, as it is shown on the picture (IV). Then

reinstall the tank for chemical agent with the mounting bracket and two mounting nuts.

Attention! When mounting the sprayer cover, the gasket should be set up on cover edge (V).

Attention! When mounting the connector to the chemical supply system for the nozzle, you should install the gasket (VI).

Assemble the air hose. To do this, in the first place you should connect to the outlet of air pump the hose in such a way, that the

valve will be located at the free ending, then secure the connector hose with band clip (VII). Connect the short connector to the

elastic hose and this connection secure with band clip (VIII). The free ending of the short connector should be pushed into the

broader ending of the bent hose. Set the handle and nozzle on the bent hose. Make sure that the individual elements adhere

closely to each other (IX).

Connect the system which is supplying a chemical agent to the nozzle. Secure hoses on connections by using band clips. At first,

connect the cable which is connecting the tank for chemical agent with a valve, and then connect the hose, which is connecting the

valve with nozzle. To avoid tangling the hose during operation you should use the hose holder which is made of a wire (X).

Attention! If you have difficulty when installing the hose to connectors, the hose ends can be soaked in hot water, allowing it to be

softened and allow for easier installation.

Installation of the blower or sprayer for chemical a agent in the powder form

In order to use the machine as a blower or for spraying the chemical agent in powder form, you should remove the tank for the

chemical agent in the manner described above. Remove the cover sprayer and replace it with a blower cover (XI). Attention! When

mounting the blower, the gasket should be set up on cover edge. Install tank for the chemical agent by removing it from its interior

all the hoses. Connection for supplying the chemical agent into the nozzle should be replaced by a cap.

Installation of the air hose should be performed as it is described above, however you should replace the short connector with long

connector, and you should not install the nozzle which is supply the chemical agent to the nozzle.

Assembly of the antistatic installation (XII)

Antistatic installation consists of a chain clamp and copper cord. Enter the copper cord to connector between the elements of the

air duct.

Attention! Make sure that the cord does not tangle in any moving parts such as, for example, the air pump.

Screw the installation clamp to the bolt of clamping ring, and left loose the chain so during operation it will continuously touch

the ground. This will allow for discharge of any static electricity to the ground and minimize the risks associated with discharges

coming from them.

Attention! Make sure that during the sprayer operation, chain is not tangled in any obstacles, operator, and will be constantly

touching the ground.

Refueling

A blend of fuel, which is intended for two-stroke engines, is used to drive the sprayer. It is forbidden to use homogenous fuel. It is

Summary of Contents for YT-86240

Page 29: ...29 RUS...

Page 30: ...30 RUS 15 II III IV V VI VII VIII X...

Page 31: ...31 RUS XI XI XII 85 25 30 1 1 3 0 ON XIII OPEN XIV 0 XV 1 2 3...

Page 32: ...32 RUS OPEN 5 6 XVI XVII 1 1 2 1 5 3 2 4 3 XVIII XIX 2 3 XX XXI...

Page 33: ...33 RUS XXII XXIII 0 3 15 20...

Page 34: ...34 RUS...

Page 36: ...36 UA...

Page 37: ...37 UA 15 II III IV V VI VII VIII IX X XI XI...

Page 38: ...38 UA XII 85 25 30 1 3 0 ON XIII OPEN XIV 0 XV 1 2 3 OPEN 5 6 XVI...

Page 39: ...39 UA XVII 1 1 2 1 5 3 2 4 3 XVIII XIX 2 3 XX XXI XXII XXIII 0 3 15 20...

Page 40: ...40 UA...

Page 41: ...41 UA...