18

GB

O R I G I N A L I N S T R U C T I O N S

recommended to use gasoline with an octane rating no lower than 85. Gasoline should be mixed with oil in the ratio of 25-30:1.

The mix should be mixed before filling the fuel tank. Do not use mixes older than 1 month. Mixing and pouring the fuel must be

carried out away from sources of ignition. Do not smoke while refueling. Fill the tank at a distance of at least 3 meters away from

starting or operating the chain saw. In order to protect the engine, you should use a good quality unleaded petrol and good-quality

oil for two-stroke air-cooled engines. Do not use oil intended for four-stroke engines. If fuel spills you should carefully rub the

remains before starting the sprayer.

Supplementing the chemical agent

Make sure that the valve of supply system for chemical agent to the nozzle is closed and spray lever is in the “0”.

Unscrew the lid of the tank, the liquid chemical agent pour through a sieve placed under the cover. This will allow to stop the

pollution that might block the installation of supplying a chemical agent to the nozzle. In the case of receiving a chemical agent in

the powder form you should not use the sieve.

Attention! Do not exceed the maximum capacity of tank, do not fill tank over the last notch on its scale.

Make sure that the thread is clean, then firmly screw on the cover.

Attention! While filling the tank with a chemical agent you should use the operating instructions supplied with the chemical agent.

In particular, you should comply with the safety instructions and use the proper protective equipment.

Starting the engine

Attention! Before starting the machine you should make sure that the valve of system for supply of chemical agent is closed.

Attention! Before starting the engine, you should connect the air hose, this will allow the proper airflow to cool the engine. Lack of

proper air flow around it can lead to overheating and engine damage which could cause a risk to your health.

Sprayer should be placed on a level, flat, hard surface. Make sure that the outlet nozzle is not directed toward the operator or

bystanders. Even if the air valve closed, the air present in the hose will be pushed out when the engine is started.

Fuel valve should be set on the “ON” position (XIII), suction valve switch in position “OPEN” (XIV). The throttle lever should be

set to “0” position (XV). Put your foot on the basis of the sprayer, hold the sprayer with one hand and with the other hand pull a

couple of times the rope starter, it will distribute the fuel at the fuel system. Do not release the starter cable, but let it slowly roll

back. Releasing the link and its rapid rolling back can damage the starter.

Move the throttle lever to “1” position and pull the starter link until the engine starts. After starting the engine you should close the

suction valve, and then let the engine run at idle for a period of 2 - 3 minutes. Then start work, adjusting the speed of the engine

with the throttle lever.

Starting the warm engine

Set the throttle lever to position “OPEN”. If the engine uses too much fuel, close the fuel valve and pull the starter cord 5 - 6 times.

Then start the engine as in the case of normal engine start.

Adjusting the rotation speed of the engine (VI)

Attention! Do not perform motor speed adjustment unnecessarily. It is recommended that the described below regulatory procedure

is carried out in an authorized repair shop.

If the engine speed does not comply with the rated speed or the engine does not stop when the throttle lever is set to its lowest

position, adjust the engine speed. To do this, pull the cable armor, which is protecting the adjusting screw. Loosen the locking

nut, then turn the screw clockwise to reduce the speed of the motor or to the left in order to increase speed. After adjustment you

should secure the position of adjusting screw by tightening the lock nut.

Stopping the engine

Before stopping the engine, close the valve of supply system of chemical agent to the nozzle or to the air duct. Then, move the

throttle lever and spray lever to the lowest position. After the cessation of the engine rotation, close the fuel valve. This will allow

to avoid the problems at next start.

Adjusting the quantity of liquid chemical agent (XVII)

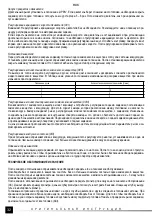

At the outlet of the nozzle there is the control knob that allows to dose quantity of chemical agent to be sprayed. The following table

refers to the maximum quantity of dosed agent at the maximum engine speed.

Knob position

The amount dosed agent [l / min]

1

1

2

1.5

3

2

4

3

Adjusting the quantity of powder chemical agent (XVIII)

Depending on the chemical agent it may be necessary to adjust the stroke of valve for chemical agent supply to the blower. This is

Summary of Contents for YT-86240

Page 29: ...29 RUS...

Page 30: ...30 RUS 15 II III IV V VI VII VIII X...

Page 31: ...31 RUS XI XI XII 85 25 30 1 1 3 0 ON XIII OPEN XIV 0 XV 1 2 3...

Page 32: ...32 RUS OPEN 5 6 XVI XVII 1 1 2 1 5 3 2 4 3 XVIII XIX 2 3 XX XXI...

Page 33: ...33 RUS XXII XXIII 0 3 15 20...

Page 34: ...34 RUS...

Page 36: ...36 UA...

Page 37: ...37 UA 15 II III IV V VI VII VIII IX X XI XI...

Page 38: ...38 UA XII 85 25 30 1 3 0 ON XIII OPEN XIV 0 XV 1 2 3 OPEN 5 6 XVI...

Page 39: ...39 UA XVII 1 1 2 1 5 3 2 4 3 XVIII XIX 2 3 XX XXI XXII XXIII 0 3 15 20...

Page 40: ...40 UA...

Page 41: ...41 UA...