19

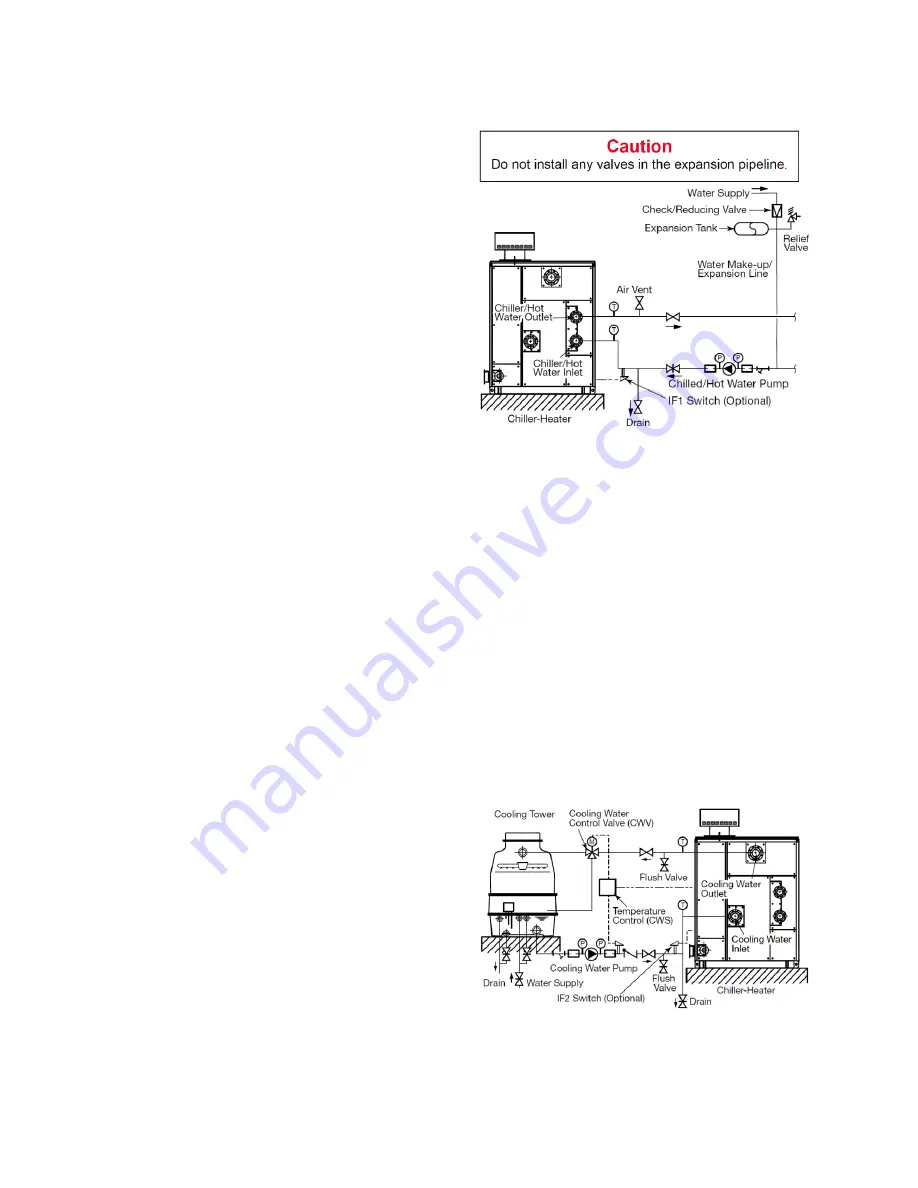

CHILLED/HOT WATER PIPING

A balance valve should be installed at

the chilled/hot water outlet and a stop

valve

should

be

installed

at

the

chilled/hot water inlet. Both valves

should be placed in close proximity to the

chiller-heater.

After thoroughly testing for leaks,

insulate the piping circuit, ensuring an

adequate vapor barrier is obtained. Be

sure to allow access to any valves, wells,

and ports that may be present. Also,

ensure the chiller-heater panels are not

restricted by the insulation.

Figure 20

– Chilled/Hot Water Piping

COOLING WATER PIPING

Cooling water should be supplied at

85°F

(29.5°C)

or less. The CH-MG Series

can adapt to cooling water down to 65°F

(18.5°C)

without the need of a mixing

valve. However, the inlet cooling water

temperature must not be below 46.4°F

(8°C)

when the cooling cycle starts, nor

may it drop to 46.4°F

(8°C)

and remain

there for more than 3 minutes at any

point in time. Such cases will result in

the generation of error code E043. This

error code will automatically reset itself

once the cooling water warms above

48.2°F

(9°C)

.

To prevent a hot slug of water from

potentially damaging the cooling tower, a

Cooling Water Control Valve

(CWV)

should be used and set so that it

bypasses into the sump of the cooling

tower for the first 2 minutes of the first

cooling cycle after the unit has changed

over from heating mode. This same

valve can also be used to divert water

that is too cold into the sump of the

cooling tower until the water has warmed

up to an acceptable temperature.

Higher temperatures than 85°F

(29.5°C)

can result in a loss of capacity. In some

cases, the burner will simply be able to

ramp up the firing rate to compensate,

but this lowers the efficiency of the unit

and should be avoided. If cooling water

exceeds 90°F

(32°C)

, the refrigerant

vapor may no longer condense properly,

which could lead to a loss of capacity as

well. If the cooling water becomes

consistently too hot, the unit may lock

out.

Figure 21

– Cooling Water Piping

Summary of Contents for AROACE CH-MG150

Page 4: ...4 EQUIPMENT DIMENSIONS Figure 1 MG150 Dimensions ...

Page 5: ...5 EQUIPMENT DIMENSIONS Figure 2 MG200 Dimensions ...

Page 6: ...6 INTERNAL WIRING DIAGRAM ...

Page 7: ...7 ...

Page 8: ...8 Table 2 Internal Wiring Diagram Legend KRCH relay has been replaced by the KCH relay ...

Page 12: ...12 INSTALLATION CLEARANCES Figure 7 Installation and Service Clearances ...