8

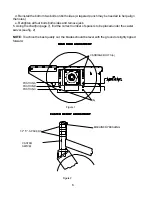

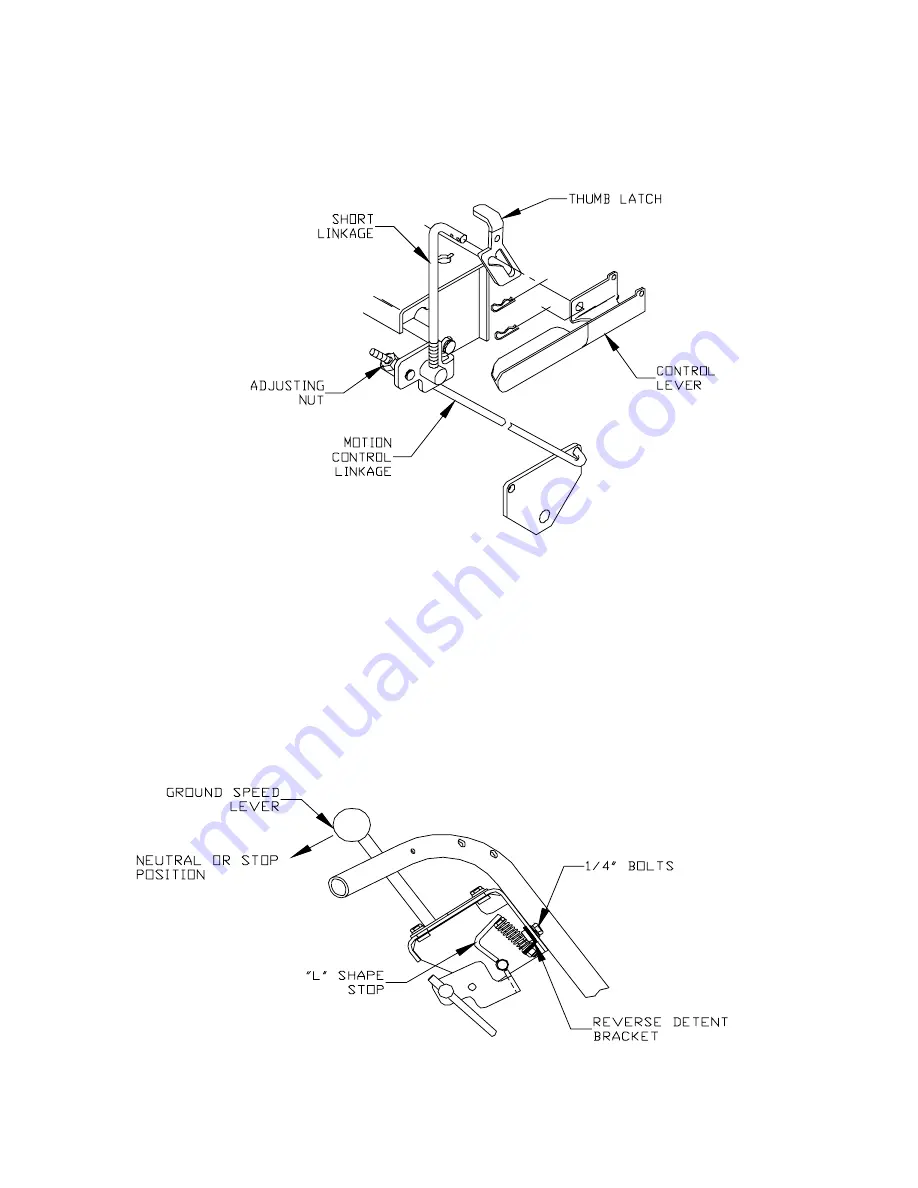

Figure 4

(Right side cut away view of console.)

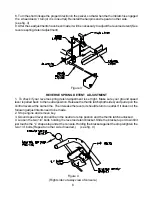

Figure 3

REVERSE SPRING DETENT ADJUSTMENT

1. To check if your reverse spring detent adjustment is set right. Make sure your ground speed

lever is pulled back to the neutral position. Release the thumb latchs(both sides) and pull up on the

control levers at the same time. Then release the levers, it should return to neutral. If it does not, the

following adjustmtents need to be made.

2. Stop engine and remove key.

3. Ground speed lever should be in the neutral or stop postion and the thumb latchs unlocked.

4. Loosen the two 1/4” bolts holding the reverse detent bracket. Slide the bracket up or down till it

just touchs the “L” shape stop under the console. Holding the bracket against the stop retighten the

two 1/4” bolts.(Repeat on other side if needed.) (see fig. 4 )

8. Turn the short linkage the proper direction in the swivel, so that when the thumb latch is engaged

the wheel doesn’t turn(or it is in neutral). Reinstall the hairpins and repeat on other side.

(see fig. 3)

9. After these adjustments have been made it will be necessary to adjust the reverse detent.(See

reverse spring detent adjustment)

Summary of Contents for KHKW36140

Page 16: ...16 SERVICE RECORD DESCRIPTION OF WORK DONE DATE SERVICE DONE BY...

Page 19: ......