English

-

43

MAINTENANCE

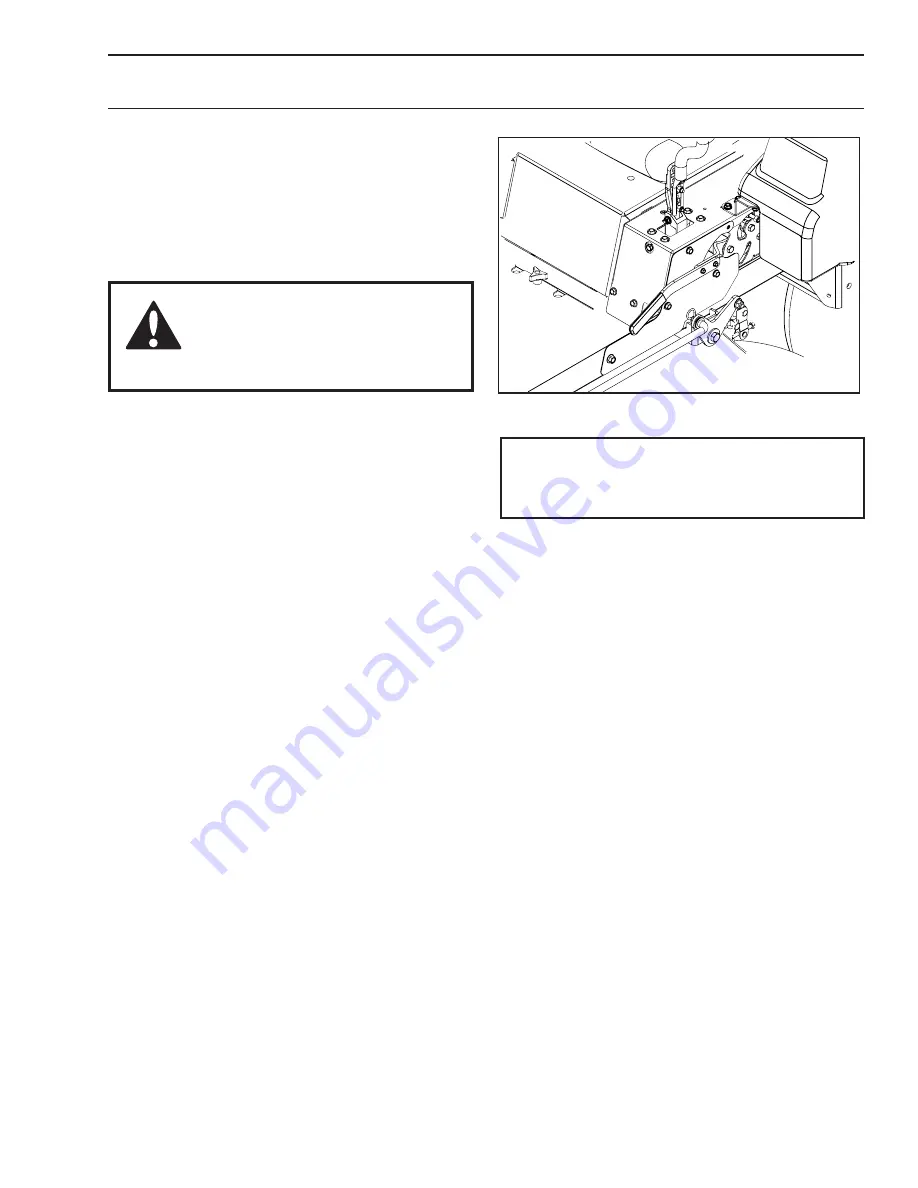

Parking Brake

Visually check that no damage is found on the lever,

links, or switch belonging to the parking brake.

Perform a standstill test and check that there is

sufficient braking action.

To adjust the parking brake, contact the yazoo/Kees

service workshop.

WARNING!

Faulty adjustment result in

reduced braking ability and can

cause an accident.

V-belts

Check every 100 hours of operation. Check for severe

cracking and large nicks.

NOTE: The belt will show some small cracks in normal

operation.

The belts are not adjustable. Replace belts if they

begin to slip from wear.

IMPORTANT INFORMATION

The machine must be absolutely standing

still when applying the parking brake.

8061-019a

Parking brake

Summary of Contents for ZELKH52250

Page 2: ...2008 HTC All rights reserved Beatrice NE Printed in U S A...

Page 72: ...English 72 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 73: ...English 73 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 74: ...English 74 SERVICE JOURNAL Action Date mtr reading stamp sign...

Page 75: ......

Page 76: ...P N 539 132406 R02 04 11 08...