14

Hardware

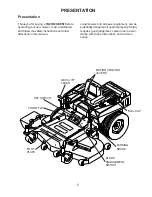

Check daily. Inspect the entire machine for

loose or missing hardware.

Air filter

See engine manufacturers specifications for

cleaning and replacement intervals.

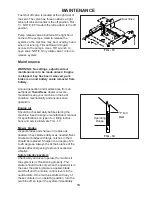

Hydraulic system

Check oil level in tank daily. Oil level should be

3/4” to 1” below the top of the tank. Check all

fittings, hoses and lines for damage or leaks.

Replace or repair any questionable lines or

fittings.

Change the oil and filter after the first 250 hours

of operation then annually after that. Drain tank

and remove filter, be sure to clean around the

tank and filter head before removal. Replace

filter and drain plug and refill hydraulic tank. Only

use MOBIL 1 synthetic oil. FIG - 15

Raise and block up the rear of the machine so

the drive wheels can rotate freely. Start the

engine at the lowest RPM possible, move the

motion control levers forward and run machine

for several minutes. Stop engine and recheck

the oil level.

If the wheels do not respond an air lock has

occurred within the system. The system must

be bled off of air or let the machine set overnight

to allow the air time to dissipate out of the oil.

DO NOT run the machine with an air lock

serious damage can occur to the pumps and

wheel motors.

Deck belt

Check every 75 to 100 hours of operation.

Check for severe cracking and large nicks.

NOTE: The belt will show some small cracks in

normal operation.

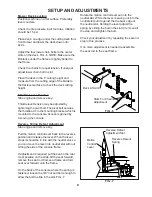

To replace belt lower the deck to its lowest

position. Remove the foot plate and belt shields.

Use a ratchet with a 9/16” socket on the spring

idler bolt to relieve the tension on the belt. Slide

the belt off of pulley and fully remove the belt.

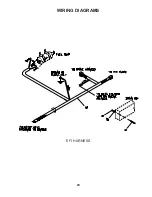

Reverse the proceedure for installation. See the

decal on the top of deck for belt routing informa-

tion. FIG - 16. After installation is complete

check the belt for twists.

MAINTENANCE

Tri-Synthetic Formula

0

ONLY USE

FIG - 15

FIG - 16

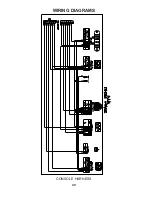

Summary of Contents for ZVKE61260

Page 20: ...20 WIRING DIAGRAMS CONSOLE HARNESS...

Page 22: ...22 WIRING DIAGRAMS FRAME HARNESS...

Page 23: ...23 WIRING DIAGRAMS EFI HARNESS...

Page 24: ......