12

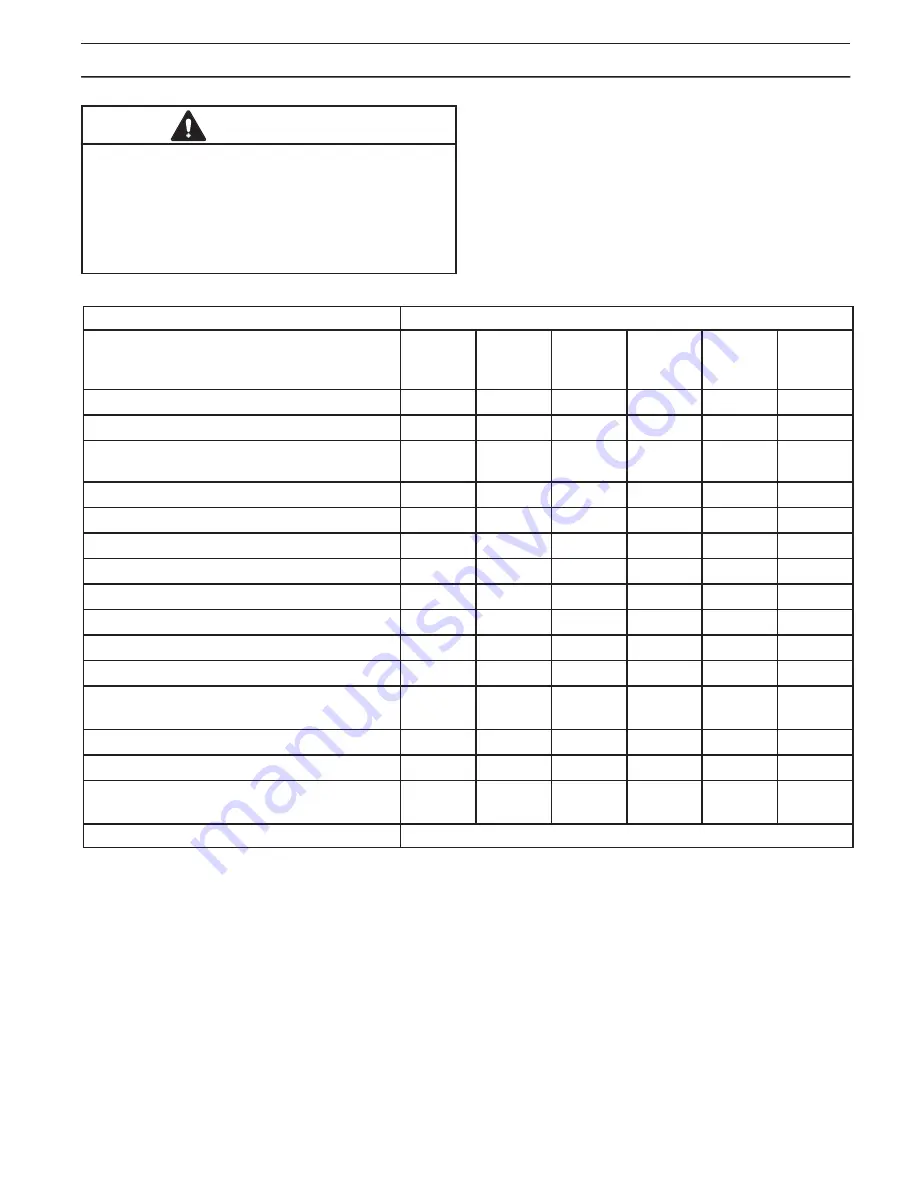

MAINTENANCE SCHEDULE

Maintenance

Intervals

Daily

First

20

hours

Every

20

hours

Every

50

hours

Every

100

hours

Every

200

hours

Check and replenish fuel

z

Check for fuel leakage

z

Check for loose or missing bolts, nuts and

screws

z

Check throttle lever operation

z

Check engine switch operation

z

Check shoulder harness condition

z

Clean fuel fi lter

z

Clean air fi lter element

*

1

z

Tighten bolts, nuts and screws

z

z

Clean spark plug and adjust electrode gap

z

Remove dust and dirt from cylinder fi ns

z

Remove carbon deposits on piston head and

inside cylinder

*

2

z

Remove carbon deposits in the muffl er

z

Clean spark arrestor screen

z

Check the condition of the crankshaft con-

necting rod etc.

*

2

z

Fuel line

It is recommended to replace every 3 years

Notice:

The service intervals should be used as a guide.

(

*

1

) The air fi lter should be cleaned more frequently in very dusty conditions.

(

*

2

) These items require proper tools and should only be performed by an authorized dealer.

WARNING

Accidental starting of the engine can cause

injury. Always remove the spark plug cap before

performing any service work to prevent acciden-

tal starting.

When starting the blower the machine should

always be completely assembled.

Summary of Contents for 65-101

Page 14: ...14 NOTES...

Page 16: ......