ESCO Equipment Supply Company

15270 Flight Path Drive, Brooksville Fl, 34604 Phone (352) 754-1117 Toll Free (800) 352-9852 Fax (352) 754-4508

www.esco.net

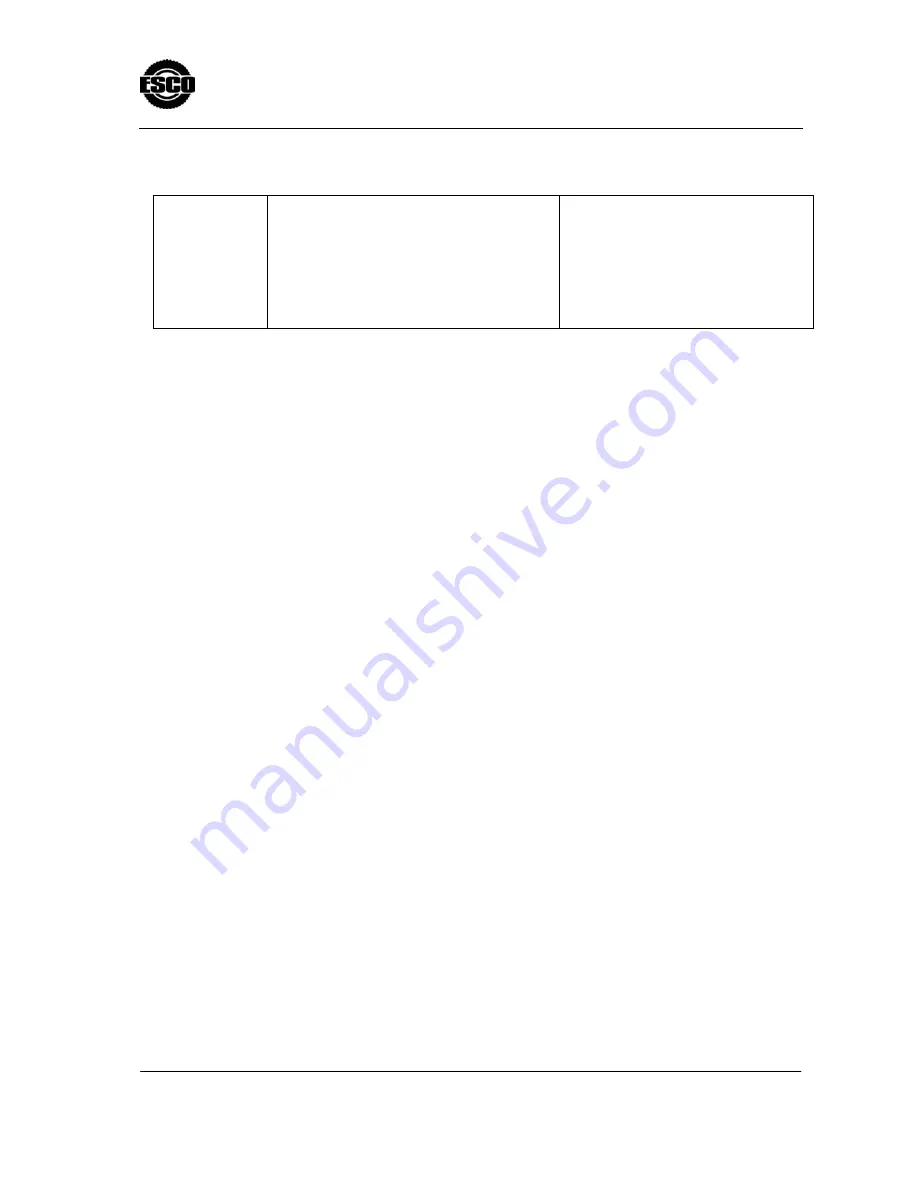

It works with

off load but it

does not move

up or move up

slowly with

heavy load.

1.

Air pressure is not enough, air pipe

removed or air inlet is plug up.

2.

one-way valve is plugged up.

3.

Hydraulic oil became thick

1.

Check the air pressure whether is

within 90-130psi and the air way

is broken or not.

2.

Check and Take every one-way

valve apart and clean them.

3.

Replace the hydraulic oil.

7. Warning:

(1). Air-operated hydraulic pressure jack is a lifting tool when using. It can not be used as a supporting tool.

Without any secured stands or solid supports on the suitable area under raised vehicle to assure security,

any operators are strictly prohibited to work after the equipment moved up. (Please carefully read the label

of <Warnings> which sticks to the operation rod).

(2). Use the Air-operated hydraulic pressure jack on a flat and resistant surface away from drains and holes.

It is not allowed to use it on a slope floor to avoid lifting objects moving or slipping, especially those

vehicle. Make sure to place some supports under the wheel to avoid slip then the equipment can be moved

up or down. (Please carefully read the label of <Warnings> which sticks to the operation rod).

(3). Always respect production requirement and use the equipment within the scope of jacking capacity.

Don’t be against the operation instruction to use it with overload.

(4). Use clean and dry air pressure. its application scope should be 90-130psi and at the same time to apply

the filtered & clean 32w hydraulic oil. (The MAX. air pressure of safety valve is 130psi)

8. Attachment:

(1). The equipment is with long extension rod and middle extension rod together. Please fix them tightly with

rope during the course of transportation to avoid damaging the host.

(2).The operation rod is packed in another carton. Please take it out and install it in the host according to the

installation indication of operation rod.