10

SUSPENSION MAINTENANCE

The Suspension System on your Go-Kart is specifically designed and set up for the smoothest possible

ride, while maintaining top performance and kart durability. Your Go-Karts suspension system uses

four shock absorbers, two on the front suspension and two on the rear suspension, to comfortably

tackle rough terrain.

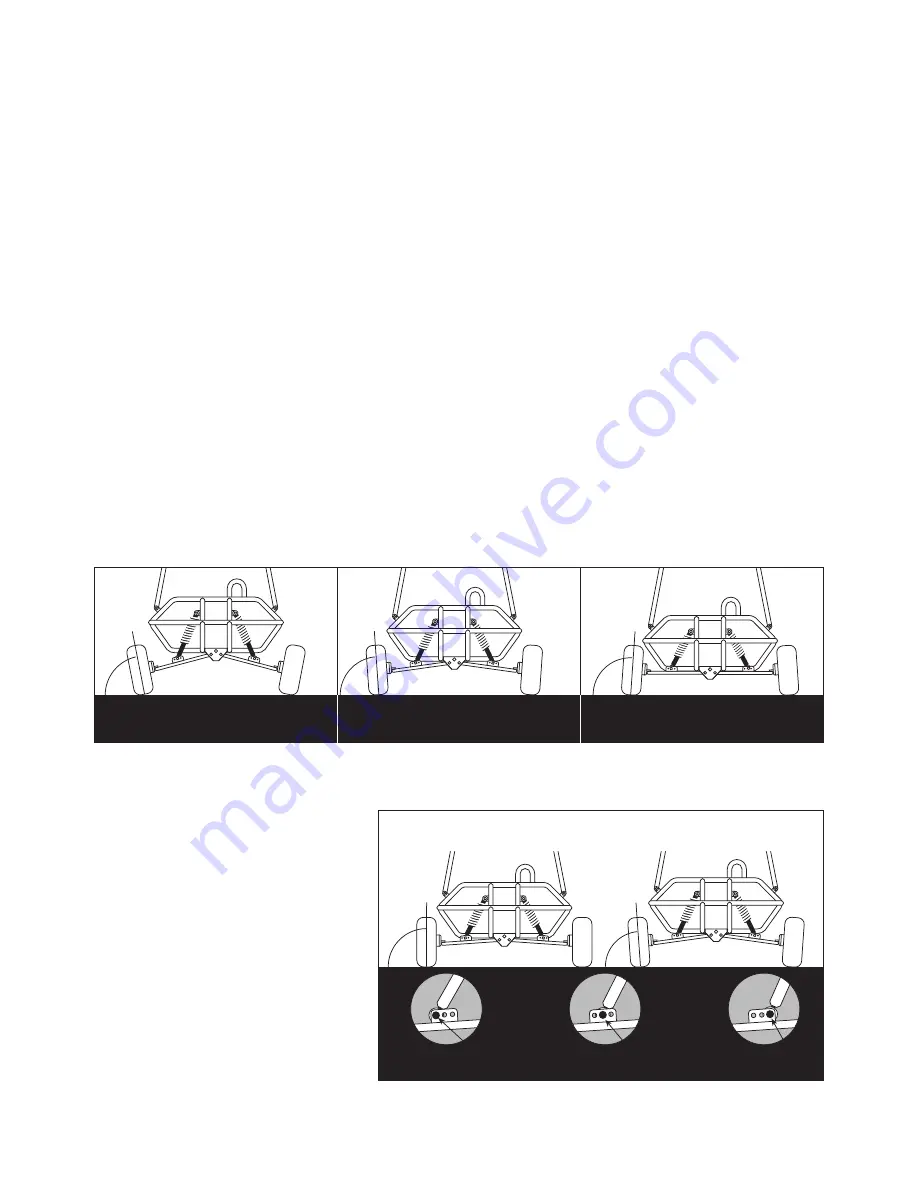

The two front shock absorbers affect the camber or slant of your front tires. You may have noticed

that your new Go-Kart has an extreme outward camber or slant of the front tires as shown in Figure

A. This is normal. They were set this way at the factory for ensuring maximum tread life on the front

tires. There are three important reasons for this outward camber:

1. The weight of the driver and/or passenger is not on the Kart.

The added weight of the driver and/or passenger pushes the front and rear suspension down.

2. The Go-Kart is not in motion.

When the Kart is in motion, the front suspension is forced down slightly.

3. The shock absorbers are new and not “broken in”.

Your new Go-Kart needs at least one hour of use to “break in” the shocks and level out the tires.

After the first 30 minutes of use, the outward camber may be reduced by one half. After 1 hour

of use the tires may have almost no or slight outward camber as shown in Figure B.

When your Go-Kart gets an inward camber on the front tires from shock wear as shown in Figure C

and steering becomes difficult, the shocks will need to be readjusted. Adjust the front suspension to

a slight outward camber as shown in Figure B by increasing the shocks. Adjust the shocks by following

the “Shock Absorber Adjustment “ instructions below. When your shocks cannot be adjusted any

tighter, they must be replaced.

Your Fun Kart has an added feature on the A-Arms for three quick Camber Adjustments Figure D.

Note: The factory attaches the shocks at position 2. You may choose to move them to position 1

and adjust shocks to set at Slight Outward Camber (Riding Position) until the shocks “break in” then

either readjust the shocks as shown

in “Shock Absorber Adjustment” or

move to position 2. Shocks may

bottom out (cannot be adjusted any

tighter) before you need to set to

position 3.

To adjust: Remove 3/8” x 1-3/4”

Bolts and 3/8” Nylock Nuts attaching

the bottom of the Shocks to the

Three Hole Brackets and move to

desired hole then reattach Shocks.

Tighten Bolts.

NOTE: Outside holes can be used for

new kart display purposes with new

shocks. (Setting at “NO CAMBER”)

A. EXTREME OUTWARD CAMBER

(NEW SHOCKS, NOT BROKEN IN)

C. INWARD CAMBER

(SHOCKS NEED TO BE

ADJUSTED OR REPLACED)

B. SLIGHT OUTWARD CAMBER

(SHOCKS BROKEN IN)

POSITION 1

OUTSIDE HOLE

POSITION 2

MIDDLE HOLE

POSITION 3

INSIDE HOLE

FIGURE D – THREE QUICK CAMBER ADJUSTMENTS

DISPLAY POSITION

RIDING POSITION

Summary of Contents for 3204

Page 20: ...20 MODEL 3204...