28

disassembly

Disassembly Tips

chanGes

We strive to make the best bikes in the world.

Because of this dedication, we continually make changes to

our bikes as needed. As the bikes are improved, assembly

and setup instructions may be affected. Any amendments to

the existing Owner’s Manual can be found on our website at

www.yeticycles.com.

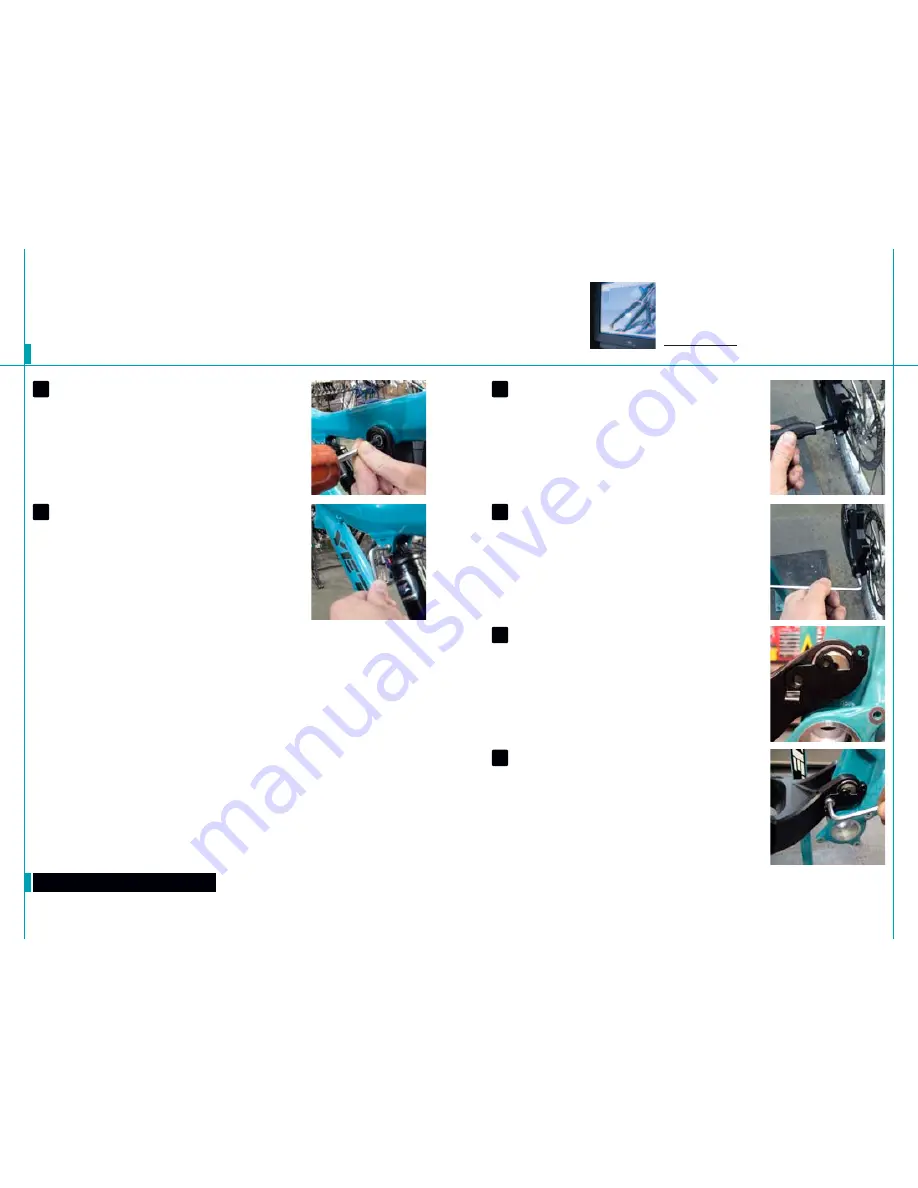

shOck and dOGbOne dissassembly

Remove the male dogbone

pivot pin bolt from the female pivot pin using a 4mm allen key. Use a

punch and a dead blow hammer to remove the female pin from the dogbone

and frame.

axle system

Slide the threaded axle through the non drive side of

the frame and the hub. Lightly grease the threads on the axle and

tighten into the axle nut on the drive side of the frame with a 5mm allen

key. Torque 40-45 in/lbs

shOck and dOGbOne dissassembly

Remove the Ti male bolt from

the 31.0 female Ti bolt holding the shock on the frame using two 5mm

allen keys. Insert the guide pin tool into the female bolt and use a dead

blow hammer to tap the bolt out of the frame. Be prepared to catch the bolt

as it exits the drive side of the frame

axle system

Tighten the pinch bolt on the non drive side dropout to

secure the axle. Use a 5mm allen key. Torque 75-85 in/lbs

asr7 frOnt derailleur mOunt

Insert the front derailleur mount

into the drive side chainstay yoke. Ensure the cable guide on the

mount is facing out.

asr7 frOnt derailleur mOunt

Attach the mount with a Ti female

M6x16.5 bolt and a M6x1x12 Ti male bolt. Ensure each bolt has the

proper washer installed. Prep the male bolt with locktite and tighten the

assembly with two 5mm allen keys.

1

2

5

1

6

2