51

TROUBLSHOOTING

ISSUE

CAUSE

CORRECTIVE ACTION

Residue Plugging 1. Incorrect Head Angle

2. Roller Mount Tube

incorrectly installed

3. Pivot arm orientation

incorrect

4. Bearing installed

incorrectly

5. Intermeshing snapping

rolls

6. Too much Spring Tension

1. Adjust head angle to 23 – 25 degrees (

see page 37)

2. Make sure the Bearing Support Tab is on the backside

of the Roller Arm Mount Tube

3. Reposition the pivot arm so that it offsets under the

snout & not under the row

4. Make sure the side of the bearing that protrudes

outside of the cast housing is facing toward the roller

(each roller should spin freely by hand)

5. Order the 5000-080 Set Back Kit (order 2 per roller)

6. Back the nut off of the push rod until the nut is flush

Stalk aren’t

“devastated”

1. Insufficient spring down

pressure

2. Operating corn head too

high

1. Tighten push rod nut on spring bushing more

2. Lower corn head until the rollers engage

Corn Head won’t

fit on head cart

1. Devastators bottom out

2. Roller won’t clear cart tire

3. Storage stands don’t rest

in the saddles on the cart

1. Adjust top rail & saddles higher on cart

2. Order 5000-082 Lift Kit (raises roller 2”)

3. Order 5000-081 Head Extensions (JD 600 & 700 series

only)

NOTES

Summary of Contents for 5000-025A

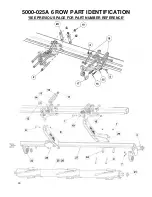

Page 39: ...39 5000 025A 6 ROW PART IDENTIFICATION SEE PREVIOUS PAGE FOR PART NUMBER REFERENCE ...

Page 41: ...41 5000 026A 8 ROW PART IDENTIFICATION SEE PREVIOUS PAGE FOR PART NUMBER REFERENCE ...

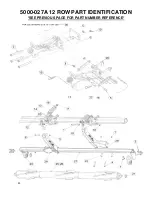

Page 43: ...43 5000 027A 12 ROW PART IDENTIFICATION SEE PREVIOUS PAGE FOR PART NUMBER REFERENCE ...

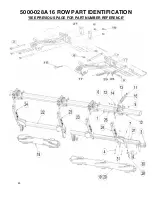

Page 45: ...45 5000 028A 16 ROW PART IDENTIFICATION SEE PREVIOUS PAGE FOR PART NUMBER REFERENCE ...

Page 49: ...49 ...

Page 50: ...50 ...

Page 52: ...52 2565 785_Rev_D 12 2018 ...