50

2940 Air Adjust Operation

Screen Control and Navigation:

SCREEN NAVIGATION:

The

MENU

icon will take you away from operation screen. Pressing

EXIT

will take you to operation screen.

Pressing

BACK

will take you to the previous screen.

FILTER DRAIN:

Pressing this icon will drain the water separator valve for 5 seconds. The water separate valve will cycle for 7 seconds

every time the system in powered on.

SETUP:

Pressing this icon will take you to a screen where you can edit the amount of up pressure to raise the row cleaner. From the

factory, this is preset at 40psi. Touch 40 to edit, will save automatically on tablet application, press OK on ISOBUS application.

The minimum you can set this is 25psi, the maximum is 100psi. If you have air bags, DO NOT set above 60psi.

SAVE PRESET:

The system will have 5 factory presets stored & named. Preset 1 being the lightest & 5 being the heavier/more

aggressive. If the operator adjusts the pressures away from a preset & wants to save these new target pressures as a preset, press MENU,

then SAVE PRESET, select which preset you want to save these new target pressures on (1

– 5), rename the preset if desired, & press

SAVE. Pressing FACTORY RESET will change all presets back to factory settings.

SYSTEM INFO:

On the system info screen, the operator can select 5 different icons, or press BACK to go back to the MENU screen or

EXIT to go back to the operation screen.

HOURS:

Air compressor hours is the amount of time the compressor has ran (or was supposed to be running), System Hours is

the amount of time the air adjust system has been activated, Duty Cycle is the percentage of time the compressor has been

engaged in accordance with system hours, (i.e. if compressor hours 5 & system hours is 50, duty cycle is 10%), & Compressor

Runtime Errors is the amount of times the compressor has ran for 15 continuous minutes.

FAULT STATUS:

This screen displays the status of the system. Anytime a CHECK FAULT STATUS message pops up in the top

left corner of the operation screen, navigate to this page to determine what may be the problem.

MAINTENANCE:

This page will display some details that should be regularly practiced to prolong the life of the Air Adjust system.

PRESSURE CHECK:

This page allows the operator to make sure his target pressures & the actual pressures are in tolerance.

The tolerance specs are +/- 7psi of the target pressure. If target is 30, actual is 35, that is within tolerance.

ABOUT:

This is info about the system & contact info for Yetter if any questions or service issues come up.

Summary of Contents for GERMINATE UNIFORMITY 2940

Page 35: ...35 6 Row Airline Diagram 6 11 or 6 12 Split Row Airline Diagram...

Page 36: ...36 8 Row Airline Diagram 8 15 8 16 Split Row Airline Diagram...

Page 37: ...37 12 Row Airline Diagram...

Page 39: ...39 16 Row Airline Diagram...

Page 40: ...40 16 31 16 32 Split Row Airline Diagram...

Page 42: ...42 24 Row Airline Diagram...

Page 43: ...43 24 47 24 48 Row Airline Diagram...

Page 45: ...45 32 Row Airline Diagram...

Page 46: ...46 36 Row Airline Diagram...

Page 47: ...47 48 Row Airline Diagram...

Page 48: ...48 54 Row Airline Diagram...

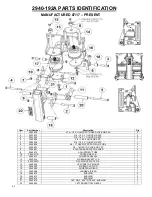

Page 78: ...78 HYDRAULIC PUMP 2940 545 PARTS IDENTIFICATION PART REFERENCE ONLY...

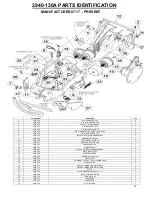

Page 82: ...82 2565 983_REV_B 09 21...