51

2940 Air Adjust Operation

Error Messages

NO BATTERY POWER:

If the 40A Breaker trips or a battery power cable becomes disconnected or damaged & insufficient

power is delivered to the Yetter 2940-103A, this message will appear. Inspect the breaker/power cables & repair.

NO CONNECTION TO THRASHER:

If the 2940-653 Thrasher module is not connected to ISOBUS or Tablet controller, this

message will appear. Check the lights on the Thrasher module (mounted to exterior of the control box), if using a

Tablet, the operating status & status 1 lights will illuminate. Make sure the tablet is connected to the WiFi signal

named AIR ADJUST. If using ISOBUS, the status 2 light will also illuminate.

HIGH COMPRESSOR RUN TIME:

If using a Yetter compressor, the system has a time limit that the compressor can run

before timing out. If the compressor runs for 15 minutes without turning off via the pressure switch, this message will

appear. Perform a leak check on the system. On hydraulic compressors, this message will appear while in transport

when no hydraulic flow is being sent to the hydraulic motor on the compressor.

NO CONNECTION BETWEEN THRASHER & MIDAC:

If there is no communication between the 2940-112A Midac control

module inside the 2940-103A control box & 2940-653 Thrasher module on the outside of the control box, this

message will appear. Check the connections/harness between the 2 modules to make sure nothing became

disconnected/damaged.

Operation Settings:

“How much Down/Lift Pressure should I be running?”

The amount of Down/Lift Pressure will vary greatly across soil types, tillage practices, soil moisture, row unit weight & many

other variables. Manage the pressure in the down &/or lift circuits in order to maintain 90%+ ground contact while keeping the

pressure between 10-60 psi. The cab controller will display the tank pressure in psi, if the compressor is engaged, a lightning

bolt will appear, & the down/lift circuits in psi. A typical starting range for residue managers (RM) would be 35psi up, 30psi

down, and 32psi WT. A typical starting range for RM/ combo would be 30psi up, 35 psi down, 37psi WT. When an ideal

pressure setting is found for a certain field condition & the operator wants to save it as a preset, press MENU, press SAVE

PRESET, select the preset you want to save over, rename the preset if desired, & press SAVE.

If the residue managers aren’t

removing enough residue, add more down pressure or subtract some up pressure. If the residue managers are being too

aggressive, subtract down pressure or add up pressure.

Normal operating ranges:

Down Pressure Bags: 10-60psi

Lift Pressure Bags: 10-60psi

Tank Pressure: The gauge at the tank will read 145psi when full. The tank pressure reading on the cab controller will be

around 100-120psi, depending with the regulator on the water separator assembly is set at. The tank has a safety relief

valve that will automatically exhaust excess pressure in the event that the pressure would exceed 175 psi.

Summary of Contents for GERMINATE UNIFORMITY 2940

Page 35: ...35 6 Row Airline Diagram 6 11 or 6 12 Split Row Airline Diagram...

Page 36: ...36 8 Row Airline Diagram 8 15 8 16 Split Row Airline Diagram...

Page 37: ...37 12 Row Airline Diagram...

Page 39: ...39 16 Row Airline Diagram...

Page 40: ...40 16 31 16 32 Split Row Airline Diagram...

Page 42: ...42 24 Row Airline Diagram...

Page 43: ...43 24 47 24 48 Row Airline Diagram...

Page 45: ...45 32 Row Airline Diagram...

Page 46: ...46 36 Row Airline Diagram...

Page 47: ...47 48 Row Airline Diagram...

Page 48: ...48 54 Row Airline Diagram...

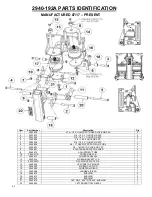

Page 78: ...78 HYDRAULIC PUMP 2940 545 PARTS IDENTIFICATION PART REFERENCE ONLY...

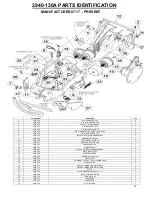

Page 82: ...82 2565 983_REV_B 09 21...