81

Troubleshooting Guide

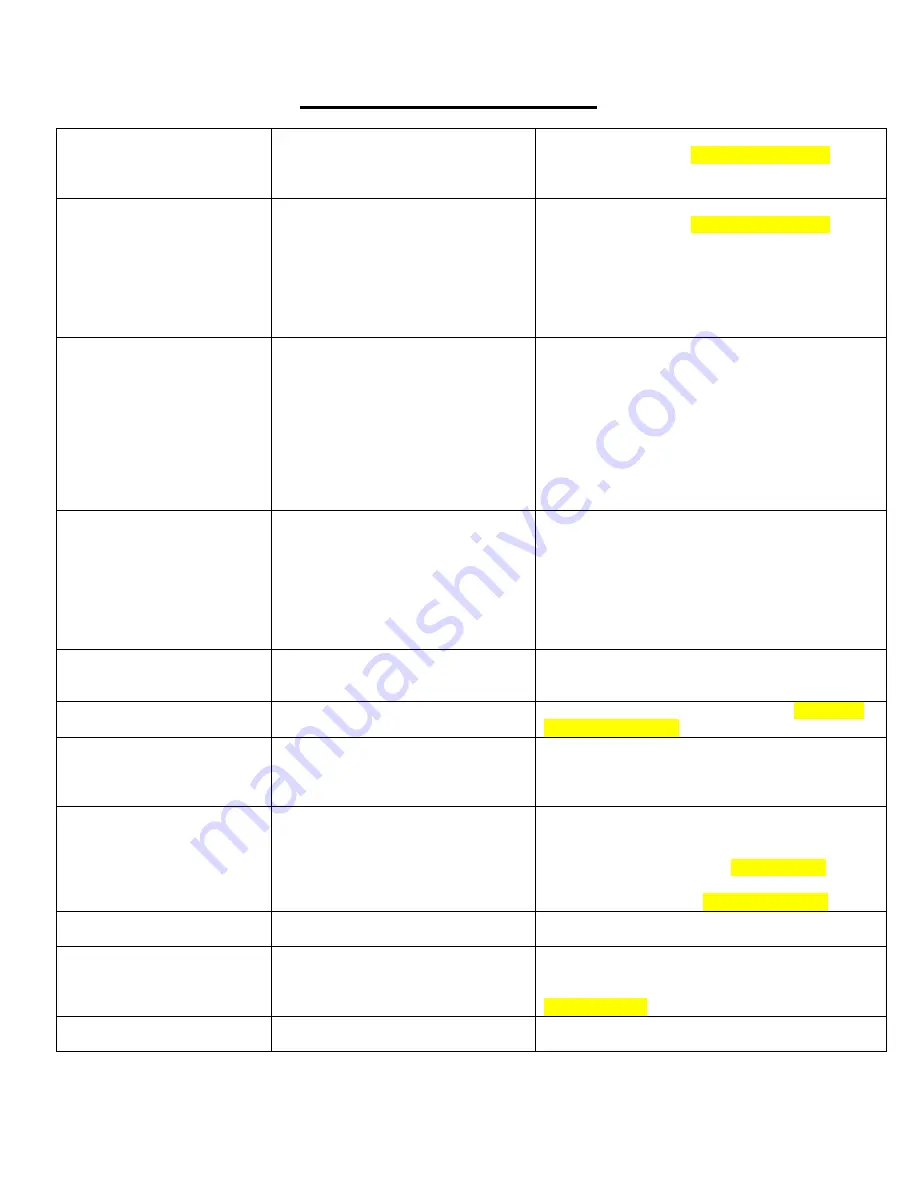

Problem

Cause

Corrective Action

Tank pressure drops when

compressor shuts off

1. improper check valve function

2. loose connections/ air leak

3. water separator drain valve

leaking

1. replace check valve on compressor

2. perform leak check

(see pages 53 & 54)

3. replace water separator drain valve

Compressor runs

continuously/air flow lower

than normal, Compressor

Run Time High warning on

cab controller if compressor

runs continuously for 15

minutes

1. excessive air usage

2. loose connections/air leak

3. Improper pressure switch function

4. clogged air filter element

5. worn compressor

6. defective safety valve

7. tank drain valve open

8. water separator valve leaking

1. decrease air usage

2. perform leak check

(see pages 53 & 54)

3. replace pressure switch

4. clean/replace filter element

5. replace compressor

6. replace safety valve

7. close tank drain valve

8. replace water separator valve

Compressor will not run

1. air system is off

2. hydraulics disengaged

3. no power to control box

4. communication harness

connection issue

5. shut off psi(145psi) reached

6. worn compressor

7. Improper pressure switch function

1. press ACTIVATE SYSTEM

2. engage compressor hydraulic circuit

3. check power connections from battery to

control box, check 2940-166 breaker at battery

4. check harnessing from compressor to the

control box

5.compressor will restart after tank pressure drops

below 125psi

6. replace compressor

7. replace pressure switch

No air output from the RU,

RD, and WT ports even

though pressure is

commanded and tank

pressure reads 75psi or

greater

1. air system is off

2. no power to the VDM

3. 75psi of tank pressure not

achieved

4. improperly functioning Mac Valves

5. communication harness

connection issue

1. press ACTIVATE SYSTEM

2. check power connections from battery to VDM,

check 2940-166 breaker at the battery

3. allow the compressor to build at least 75psi

4. replace Mac Valves as needed

5. check the end of all connectors to make sure

terminal pins are all flush to the end of the male

connectors and the connectors are seated tightly

Low or sporadic tank

pressure reading

Air leaking out regulator knob

water separator/regulator assembly

plumbed incorrectly

plumb water separator/regulator correctly

(air compressor

water separator

exit regulator

side

enter control box inlet port)

Compressor struggles to

build/won’t build 145psi

flow control valve adjustment needed flow control valve adjustment needed

(see page

53 for instructions)

No connection to Thrasher or

No connection between VDM

& Thrasher

improper communication harness

connection between VDM and

Thrasher

1. Make sure the lights on the Thrasher are

laminated

2. Make sure 2940-654 Thrasher to Midac is

plugged in

Excessive noise from

compressor

1. loose mounting bolts

2. worn bearings

3. cylinder or piston is worn

4. compressor over speeding

1. tighten bolts

2. replace compressor

3. rebuild compressor

4. check compressor RPMs

(see page 53)

& slow

motor down if needed, hydraulic plumbing of the

compressor is incorrect

(see page 28 - 29)

Excessive moisture in

discharge

1. excessive water in air tank

2. high humidity

1. drain tank, drain tank more frequently

2. move compressor to area with less humidity.

Hydraulic motor front seal

leakage

1. case drain clogged or unplugged

2. case drain not plumbed correctly

1. remove case drain plumbing and clean out

debris/obstruction, replace seal

2. Plumb case drain according to the instructions

(see pages 30)

, replace seal

Row cleaners do not react

uniformly

1. check each row cleaner for drag

1. replace bushings/parts causing drag or check

hardware tightness

Summary of Contents for GERMINATE UNIFORMITY 2940

Page 35: ...35 6 Row Airline Diagram 6 11 or 6 12 Split Row Airline Diagram...

Page 36: ...36 8 Row Airline Diagram 8 15 8 16 Split Row Airline Diagram...

Page 37: ...37 12 Row Airline Diagram...

Page 39: ...39 16 Row Airline Diagram...

Page 40: ...40 16 31 16 32 Split Row Airline Diagram...

Page 42: ...42 24 Row Airline Diagram...

Page 43: ...43 24 47 24 48 Row Airline Diagram...

Page 45: ...45 32 Row Airline Diagram...

Page 46: ...46 36 Row Airline Diagram...

Page 47: ...47 48 Row Airline Diagram...

Page 48: ...48 54 Row Airline Diagram...

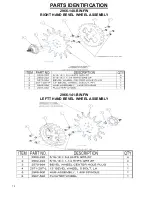

Page 78: ...78 HYDRAULIC PUMP 2940 545 PARTS IDENTIFICATION PART REFERENCE ONLY...

Page 82: ...82 2565 983_REV_B 09 21...