6

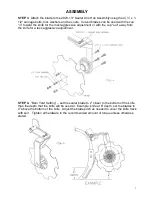

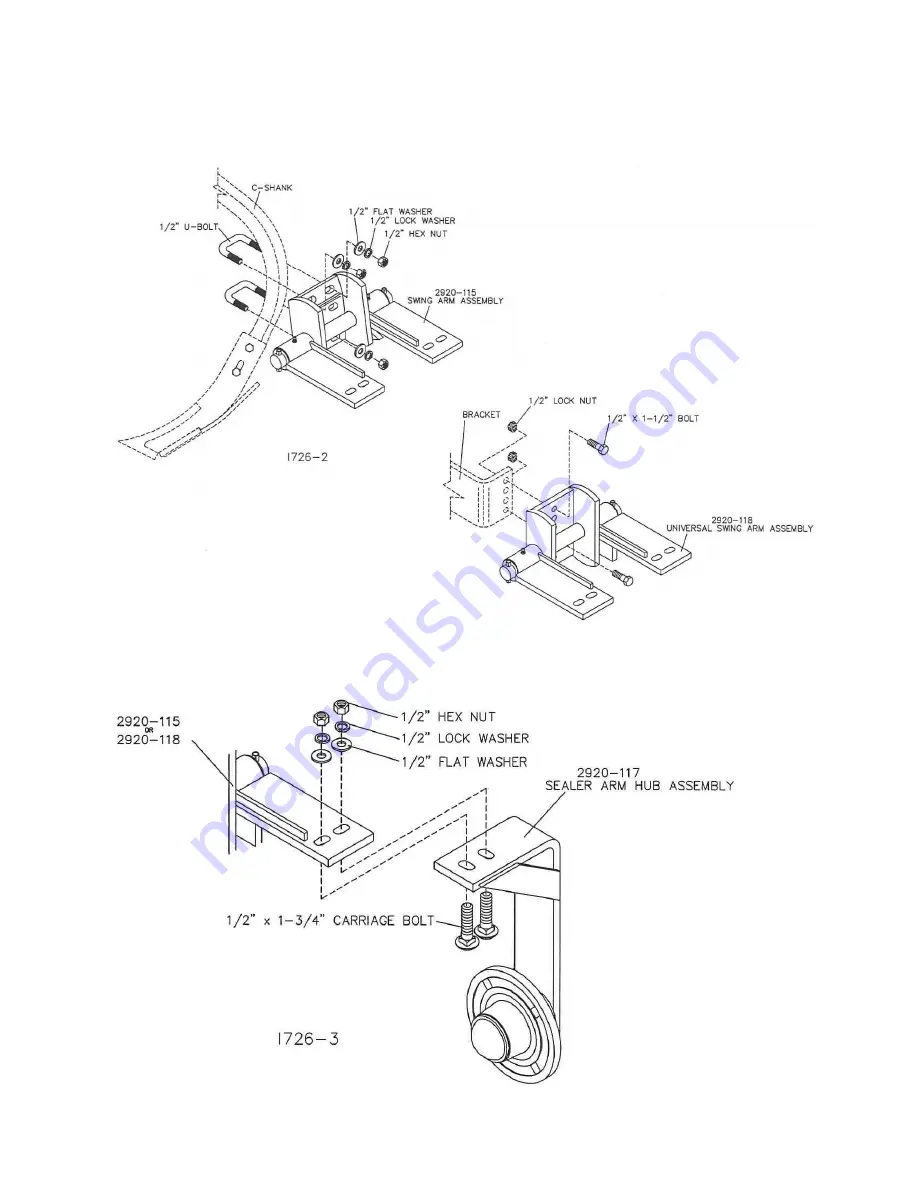

ASSEMBLY

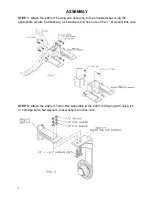

STEP 1.

Attach the 2920-115 swing arm assembly to the shank/bracket using the

appropriate u-

bolts, flat washers, lock washers and hex nuts or the ½” bolts and lock nuts.

STEP 2.

Attach the 2920-117 Arm Hub Assembly to the 2920-115 Swing Arm using the

½” carriage bolts, flat washers, lock washers and hex nuts.

Summary of Contents for MAX SEALER PLUS 2920 Series

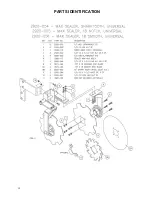

Page 9: ...9 PARTS IDENTIFICATION...

Page 10: ...10 PARTS IDENTIFICATION...

Page 11: ...11 PARTS IDENTIFICATION...

Page 12: ...12 PARTS IDENTIFICATION...

Page 13: ...13 PARTS IDENTIFICATION...

Page 14: ...14 PARTS IDENTIFICATION...

Page 16: ...16 2565 727_REV_C 09 2023...