Soldering iron part

1. Connect the soldering iron handle, put the iron on the iron holder.

2. On iron power switch ,the display beside Red LED bright ,the display window

shows iron preset temperature 2 seconds ,iron start from 200

high-speed

°C

heating until the temperature rose to the preset temperature and stable, then

able to work properly.

3. Print front panel “UP”(temperature rise key)”/”DOWN(drop in temperature key)”

adjust what you need temperature.

Dear User! Our air gun and soldering iron handle adopt high strength stainless

steel tube, the machine must be inspected or calibrated four times in normal

working condition during the production process, the copper tube could be slight

yellowing due to high temperature! When use the new machine first time, it is

normal that the steel tube at a slight yellowing , please be assured!

Special Instructions:

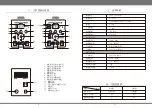

VIII. Symbol Show

1. The displays

--- , hot air gun sleep state, it shows air gun handle enter into

show “

”

sleep state.

2. The displays show “S-E”, it means the soldering iron and hot air gun of sensor is

having a problem or other parts have faulty, then the machine stops heating

output signal.

3. LED Digital last place the decimal point: - Always bright is the entire heating;

- goes off to stop heating; - flashing at a constant temperature all the way to the

current state.

4. Shows “---” always flashing, it means that the machine into standby, prompt you

turn off the power switch, more human and saving energy.

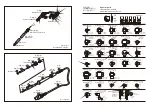

1. Unscrews the nut NO.1, and then removes the steel tube NO.2, followed by rem-

oving the tips which is going to be replaced.

2. For the replacement of heating core’s element can be performed by unscrewing

the plastic cap NO.4, pulls out gently the heating core’s element NO.6 along with

the circuit board NO.7,please carefully remember the connection of spring NO.5.

3. The iron core from the circuit board welding, the replacement of the heating core,

can be fitted well. Note that the order of the iron core wire connection.

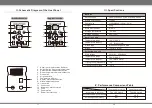

IX. Interchangeable Component Description

Attention:

When replacing the heating element, be careful not to damage the ground; do not

damage the cable of fan; while back install handle, the handle is fixed on the column

should be fixed on the pipe in the hole.

15

16

1. Ensure the hot air rework is fully cooled down before replacing the element

2. Figure, loosen the two screws on the handle.

3. Unscrew the handle assembly 1, and then remove the handle shell 2.

4. Gently takes out the fan, loosen the three screws to remove the fixed wiring

board.

5. The wiring board in turn, heating elements connector apart from the wiring board,

pay attention to its connection position.

6. Remove from the heat pipe heat body wrap body with mica paper, careful not

broken ground wire of the steel.

7. Wraps well with the new heater mica, inserted into the tube, the attention heater

to install in place.

8. According to the original location of the connection to connect heater.

9. When the reverse process by open bottles and handle back.

Replacement of Hot Air rework heating element (Figure 3)

2. Air gun manual work state:

A. Open air gun switch, the display shows the air gun preset temperature 2 seco-

nds, air gun start from 100°C high-speed heating until the temperature rose to

the preset temperature and stable, then able to work properly.

B. Print front panel “UP(temperature rise key)”/“DOWN(drop in temperature key)”

adjust what you need temperature.

C. Manual Mode, air gun handle back into the air gun frame,air gun also keep the

currently work temperature. This mode is very suitable for all-too-frequent

soldering ,it can save air gun heating up time, raise soldering efficiency.

Replacement of the soldering iron’s tip and soldering iron heating core’s

element (Figure 4)