37

8.2 Changing the cutting tool

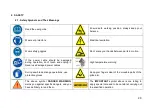

8.2.1 Use

protective gloves when replacing

cutting tool.

8.2.2 Cut the electric connection of the machine.

8.2.3 Open the upper protection cover. (FIGURE 2-NO: 6)

8.2.4 With the help of 6 Allen key (given with the machine), demount the bolt (FIGURE 10-NO: 43) from its location..

Take the washer (FIGURE 10 NO: 44) and the exterior coupling (FIGURE 10 NO: 45) to the outside.. Take the

saw cutter group (FIGURE 10 NO:47) over the rotor shaft (FIGURE 10 NO: 48) by taking, replace it with a new

group saws.. After replacing the saw cutters, do the opposite of the demounting procedure and tighten the bolt.

(ON KM 213 MODELS)

8.2.5 Push the blade-changing button (FIGURE 6 / 9 NO: 25). Bearing tightening the saw group will go up (FIGURE 9

NO: 41). Take the idle tightening bearing and take out the saw group. Mount the saw group, prepared according

to the profile to be processed, on the shaft. Push the blade-changing button again and mount the tightening

bearing that you took off.

(ON KM 215 MODELS)

WHEN REPLACING THE MILLING CUTTER GROUP, ENSURE THE CUTTERS ROTATE IN THE

CORRECT DIRECTION

.

Summary of Contents for KM 213

Page 3: ...3 ...

Page 4: ...4 BOYUTLAR DIMENSIONS РАЗМЕРЫ RESİM FIGURE РИСУНОК 1 ...