YG125-30B

Maintenance Manual

Inspection and adjustment

29

Valve clearance

Notice:

While adjusting the valve clearance, the engine shall

be cold.

(Temperature

<

35

℃

)

Noise will stem from too big valve clearance. However if

there is too small gap or even no gap at all,

closing of

the valve will be hindered, which will cause many

problems such as engine stall, power loss, etc. Therefore,

the valve clearance must be checked periodically.

The valve clearance should be inspected and adjusted on

a cold engine by the following procedures:

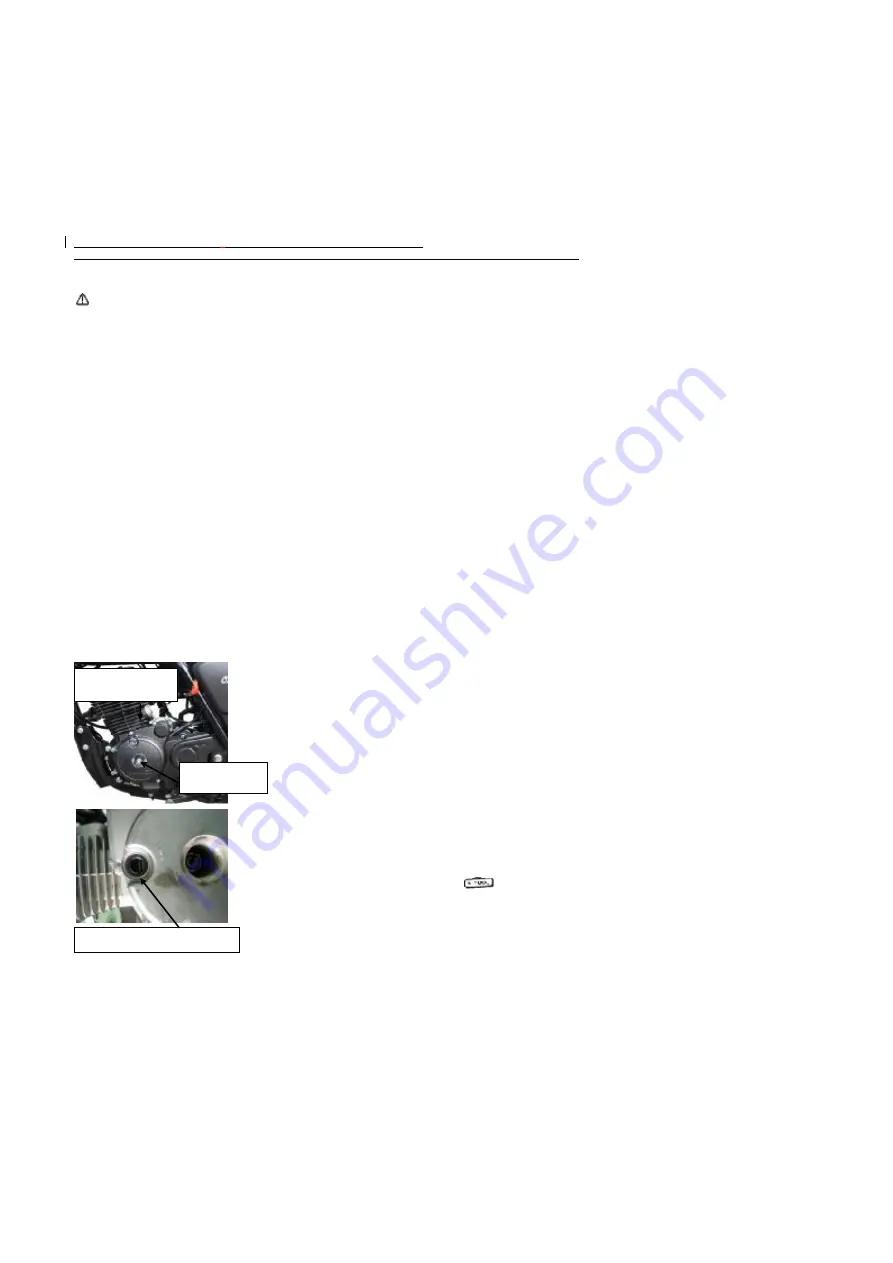

Remove the caps of the central hole and the ignition

timing observation hole on the left crankcase cover.

Remove the caps of the two air valves on the cylinder

head.

Turn the nut of the flywheel clockwise until the engraved

“

T

”

mark on the flywheel aligns with the engraved line on

the top of the crankcase cover, and both intake and

exhaust rock arms do not move but stop at their loosest

position, which shows that the piston is in its top dead

center position of the compressing stroke. If the

“

T

”

mark

is near its right position but rock arms will move

apparently when flywheel rotate a small angle, the

flywheel is not in the compressing stroke but

exhaust/intake stroke. In this case, continuously turn the

flywheel clockwise for 360 degrees to the top dead center

position of the compressing stroke, where the valve

clearance can be adjusted. Afterwards, check the valve

clearance by inserting a clearance gage into the gap

between adjusting screw and the end of the valve.

The specified valve clearance is : 0.06-0.08mm for intake

valve and 0.06-0.08mm for exhaust valve respectively.

If clearance adjustment is needed, loosen the locking nut

on the rock arm, turn the adjusting nut till a slight

resistance is felt on the inserted right clearance gage.

At the end of the adjustment, tighten the

“

Locking out

”

to

prevent loosening and another check to make sure that

the valve clearance is OK before all those dismounted

caps are refitted on.

While adjusting, unscrew the retaining nut and then turn

the adjusting screw until you feel that the clearance

gauge is slightly pulled. Then secure the adjusting screw

using the valve adjusting tool

, and then screw the

retaining screw. And finally, check the valve clearance.

Upper eyehole cover

Eyehole cover

Confirm the upper dead point

Summary of Contents for YG125-30B

Page 99: ...YG125 30B Maintenance Manual Frame and exhaust system 106 10 Frame and exhaust system...

Page 130: ...YG125 30B Maintenance Manual Illumination signal system 136 Circuit schematic drawing...

Page 141: ...YG125 30B Maintenance Manual Engine management system 147 Circuit schematic drawing...

Page 151: ...YG125 30B Maintenance Manual Electrical System Diagram 157 19 Electrical System Diagram...