YG125-30B Maintenance Manual

Crankcase, crankshaft and Shift mechanism

89

Crankcase, crankshaft and Shift mechanism

Maintenance notice

Crankshaft and balance shaft

Troubleshooting

Variable transmission system

Crankcase

Maintenance notice

To carry out the maintenance stated herein, the engine must be removed from the frame.

To repair the crankshaft, balance shaft or variable transmission system, the left hand crankcase and the right hand

crankcase must be separated, which is known as crankcase dissection. Before crankcase dissecting, the following parts

and components of the engine shall be removed:

1 Right hand crankcase, clutch, gear shifter

2 Cylinder head cover, camshaft, cylinder head, cylinder and piston (See

“

Cylinder head, cylinder and piston

”

);

3 Left front cover, rotor assembly, electrical starting transmission system (See

“

Magneto and electrical starting

system

”

);

4 Driving drive sprocket, shift switch.

Before assembling, clean all parts and components with cleaning agent and dry them with compressed air.

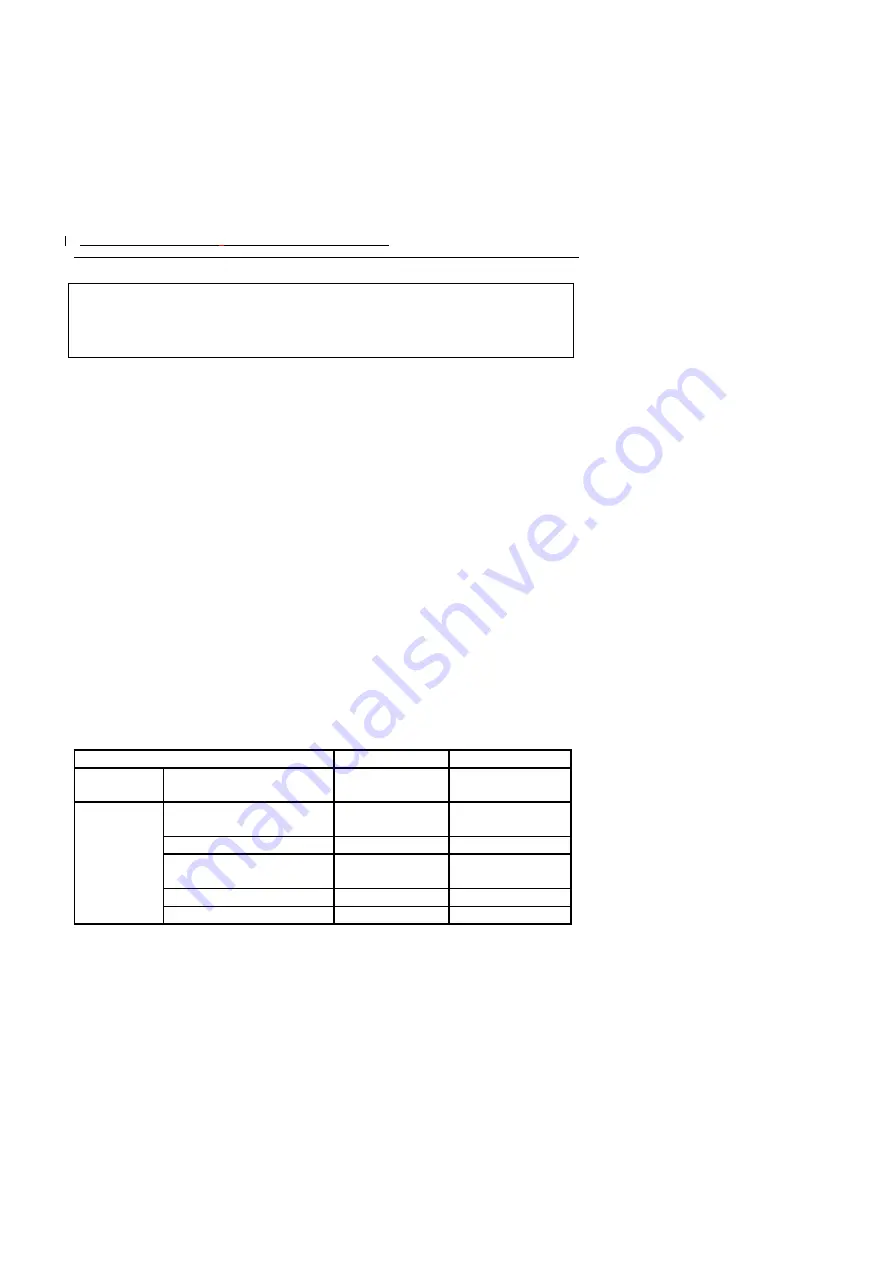

Technical specifications & maintenance benchmark

Item

Standard value

Maintenance limit value

Shift fork claw

thickness

Gear shift fork

6.05

~

5.40

5.80

Crankshaft

Connecting rod small end bore

diameter

Ф

20.03

~Ф

20.038

Ф

20.063

Disc planeness

0.028

~

0.042

0.06

Connecting rod big end radial

clearance

0.30

~

0.60

0.80

Radial runout

0.03

0.10

Left crank journal

Ф

29.959

~Ф

29.98

Ф

29.87

Summary of Contents for YG125-30B

Page 99: ...YG125 30B Maintenance Manual Frame and exhaust system 106 10 Frame and exhaust system...

Page 130: ...YG125 30B Maintenance Manual Illumination signal system 136 Circuit schematic drawing...

Page 141: ...YG125 30B Maintenance Manual Engine management system 147 Circuit schematic drawing...

Page 151: ...YG125 30B Maintenance Manual Electrical System Diagram 157 19 Electrical System Diagram...