YG48Q-5A Maintenance ManualRear wheel and rear suspension device

126

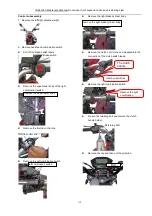

Rear fork bearing inspection

Replace the inner shaft and coat of the bearing

。

face and

apply lithium base grease on the bearing. After the

installation is complete, check whether the bearing can

rotate.

Coordination clearance: 0~0.5mm.

Disassemble, assemble and check rear absorber

Remove the bolt connecting the frame

Remove the bolt connecting the rear fork.

To install the rear damper:

Installation is in the reverse order of removal. While

installing, use the upper hole for the lower installation of

the damper.

Notice:

Before removing the damper, the tightening torque of

the bolt connecting the frame is 30-40N.m, and the

tightening torque of the bolt connecting the rear fork

is 30-40N.m

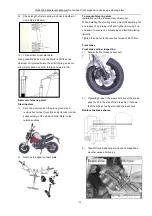

Rear Brake

Pulling the front & rear brake, checking the wear and tear

of the brake shoe. If the mark "

△

" on the drum brake

cover and also on the brake cam alignment, shows the

brake shoe has been touched the wear limit. Please

change it.

1. Dismantle rear brake caliper bolt

2

、

Operating brake, if the wears limit line of the brake shoe

touch to the side of the brake disc. It shows that the brake

shoe has touched the wear limit.

Remove the brake on the rear wheels

3

、

Take off rear brake caliper and check brake shoe

whether exceed limit value

Bol

t

Bol

t

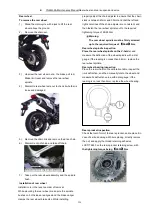

Summary of Contents for YG48Q-5A

Page 38: ...YG48Q 5AMaintenance ManualFuel system 41 4 Fuel system...

Page 92: ...YG48Q 5AMaintenance ManualFrame and exhaust system 105 10 Frame and exhaust system...

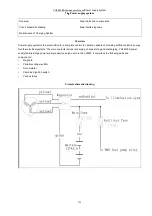

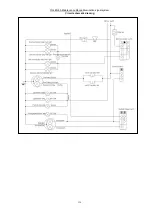

Page 123: ...YG48Q 5A Maintenance ManualIllumination signal system 136 Circuit schematic drawing...

Page 126: ...YG48Q 5A Maintenance ManualIllumination signal system 139...

Page 133: ...YG48Q 5A Maintenance ManualEngine management system 146 Major parts and components...

Page 134: ...YG48Q 5A Maintenance ManualEngine management system 147...

Page 144: ...YG48Q 5A Maintenance ManualElectrical System Diagram 157 19 Electrical System Diagram...