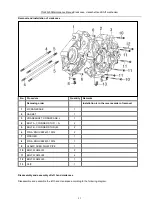

YG48Q-5AMaintenance ManualCrankcase, crankshaft and Shift mechanism

98

No.

Procedure

Quantity

Remarks

Sequence of disassembling

Assembling is in the reverse order of

disassembling.

1

KICK-START SYSTEM

1

2

CIRCLIP 17

,

1

1

a

PLATE, RACHET, GUIDE

1

b

BOLT M6×20

2

c

RACHET, KICK STARTER

1

d

GEAR, KICK STARTER

1

e

SPRING

1

f

SUPPORT, SPRING, RACHET

1

g

SPRING

1

h

SUPPORT, SPRING, START

1

i

WASHER 17

1

j

WASHER 20

2

k

SHAFT, KICK STARTER

1

l

CIRCLIP 20.2×1×27

1

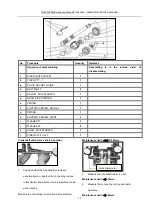

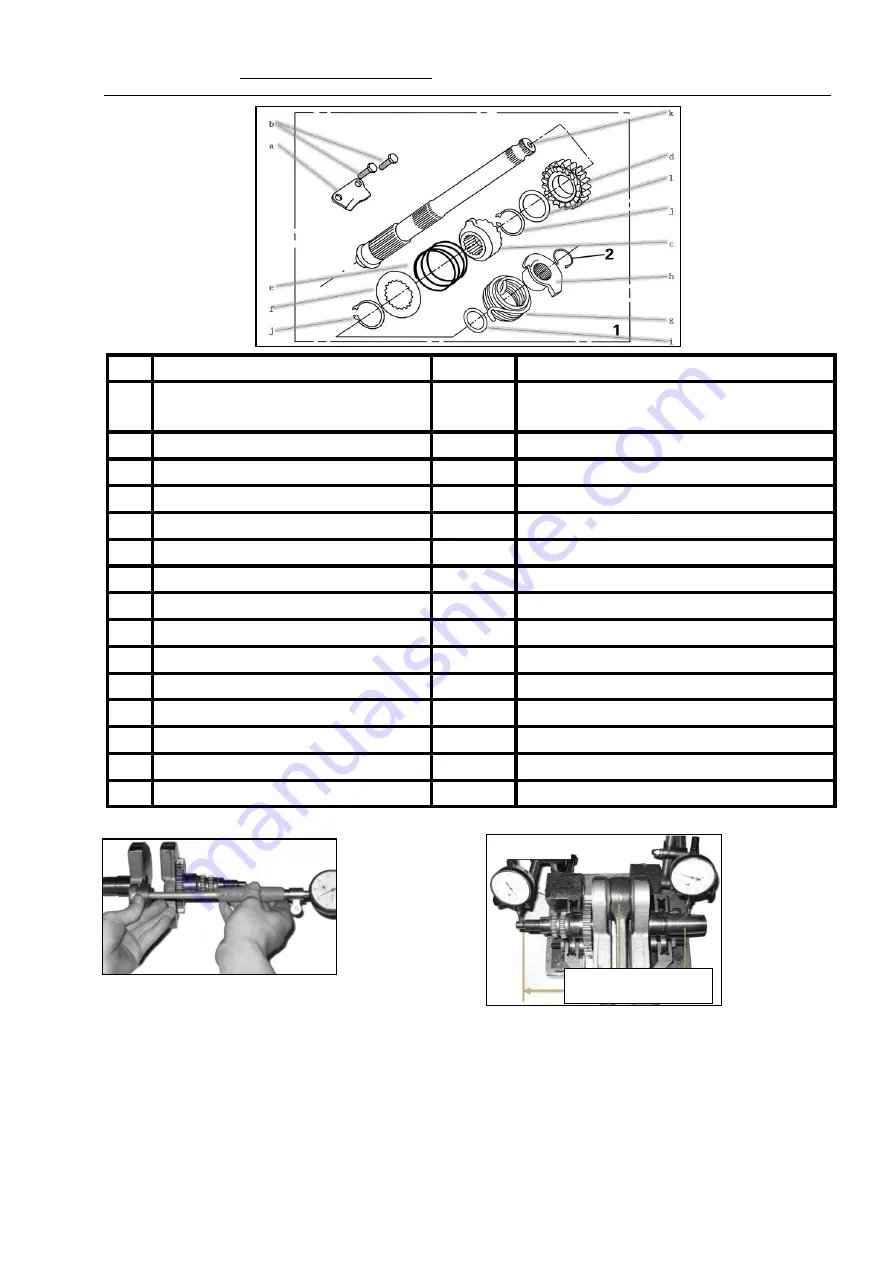

Crankshaft and balance shaft inspection

1.

Check whether the crankshaft journals are

abnormally worn, whether the connecting rod can

rotate flexibly and whether there is significant noise

while rotating.

Measure the connecting rod small end bore diameter.

Maintenance limit:

≤Ф

20.063mm.

2.

Measure the crankshaft radial run out.

Maintenance limit:

≤

0.10mm.

3.

Measure the connecting rod big end radial

clearance.

Maintenance limit:

≤

0.06mm.

Inside micrometer

Summary of Contents for YG48Q-5A

Page 38: ...YG48Q 5AMaintenance ManualFuel system 41 4 Fuel system...

Page 92: ...YG48Q 5AMaintenance ManualFrame and exhaust system 105 10 Frame and exhaust system...

Page 123: ...YG48Q 5A Maintenance ManualIllumination signal system 136 Circuit schematic drawing...

Page 126: ...YG48Q 5A Maintenance ManualIllumination signal system 139...

Page 133: ...YG48Q 5A Maintenance ManualEngine management system 146 Major parts and components...

Page 134: ...YG48Q 5A Maintenance ManualEngine management system 147...

Page 144: ...YG48Q 5A Maintenance ManualElectrical System Diagram 157 19 Electrical System Diagram...