Yingli Solar PV Modules, Installation and User Manual

page 4

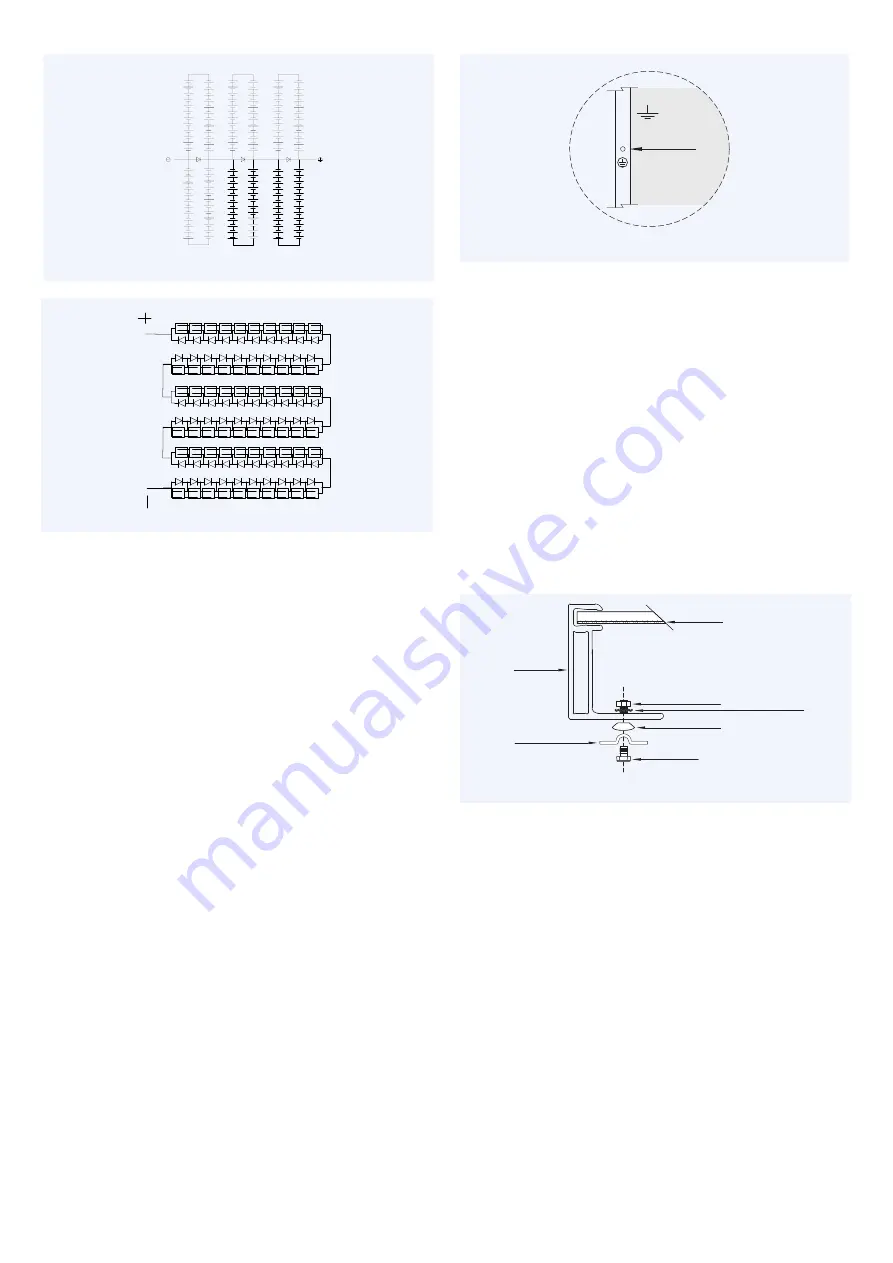

Grounding Holes

ø0.236in (6mm)

PV Laminate

Backing Nut

Toothed Lock Washer or KEPS Nut

Cup Washer

Aluminum

Frame

Screw

Equipment

Grounding

Conductor

Figure 7-1: Electrical circuitry of cells and bypass diodes

Figure 7-2: Electrical circuitry of cells and bypass diodes

In the event of a known or suspected diode failure, installers or maintenance

providers should contact the company the PV modules were purchased from.

Never attempt to open the junction box of a Yingli Solar PV module yourself.

PV Array Grounding

For optimal performance, Yingli Solar recommends that the negative pole of the

PV array be connected to ground.

Equipment Grounding

The frame of the PV module, as well as any exposed non-current-carrying metal

parts of fixed equipment that are able to become energized by the PV system,

must be connected to the equipment grounding conductor (EGC) in order to

prevent electrical shock. Even when applicable regulations, code requirements,

and standards do not require safety-related grounding, Yingli Solar recommends

grounding all PV

module frames in order to ensure the voltage between

electrically conductive equipment and earth ground is zero in all circumstances.

Proper equipment grounding is achieved by bonding all exposed non-current-

carrying metal equipment continuously to one another using an appropriately

sized EGC or racking system that can be used for integrated grounding (see

Option B in Grounding Methods below).

Yingli Solar PV modules employ a coated aluminum frame for corrosion

resistance. In order to properly ground the module frame, the coating must be

penetrated.

The potential for corrosion due to the electrochemical action between dissimilar

metals in contact is minimized if the electrochemical voltage potential between

the dissimilar metals is low. The grounding method must not result in the direct

contact of dissimilar metals with the aluminum frame of the PV module that

will result in galvanic corrosion. An addendum to UL Standard 1703 “Flat Plate

Photovoltaic Modules and Panels” recommends metal combinations not exceed

an electrochemical potential difference of 0.5 Volts.

The frame rails have pre-drilled holes marked with a grounding sign, as

illustrated in Figure 8. These holes should be used for grounding

purposes and

must not be used for mounting the PV modules. Do not drill additional holes

into the frame rails.

Figure 8: Grounding hole detail

The following grounding methods are available:

Option A: Screw Assembly (see Figure 9)

1. A grounding screw assembly must be attached at a designated grounding

hole location using only stainless steel hardware. Insert an M5 stainless

steel screw first through the stainless steel cup washer, and then through the

grounding hole.

2. Loosely engage a stainless steel backing nut and toothed lock washer to the

screw.

3. Bend the EGC into an omega (Ω) shape to tightly fit between the partially

installed screw head and cup washer. The EGC shall be exclusively in contact

with stainless steel.

4. Tighten the screw to 2.3 N∙m torque. The toothed lock washer should be

visibly engaged to the frame.

5. Route the appropriately sized EGC in such a way as to avoid contact with the

aluminum module frame.

Figure 9: Grounding screw assembly detail

Option B: Racking Manufacturer Integrated

Grounding Methods

Yingli Solar PV modules can be grounded by bonding PV modules to a grounded

racking system. Integrated grounding methods must be certified for grounding

PV modules and must be installed in accordance with the specified instructions

of their respective manufacturers.

Option C: Additional Third-party Grounding Devices

Yingli Solar PV modules can be grounded using third party grounding devices so

long as they are certified for grounding PV modules and the devices are installed

according to the manufacturer’s specified instructions.

M E C H A N I C A L I N S TA L L AT I O N

General

Yingli Solar PV Modules have been certified for a maximum static load on the

back of the module of up to 2400 Pa (i.e. wind load) and a maximum static load

on the front of the module of up to either 2400 Pa or 5400 Pa (i.e. wind and

snow load), depending on the module type (please refer to the data sheet for

Figure 7-1: Electrical circuitry of cells and bypass diodes