INST

ALLER'S

INSTRUCTION

INST

ALLER'S

INSTRUCTION

P17 OF 36

P18 OF 36

INSTALLATION

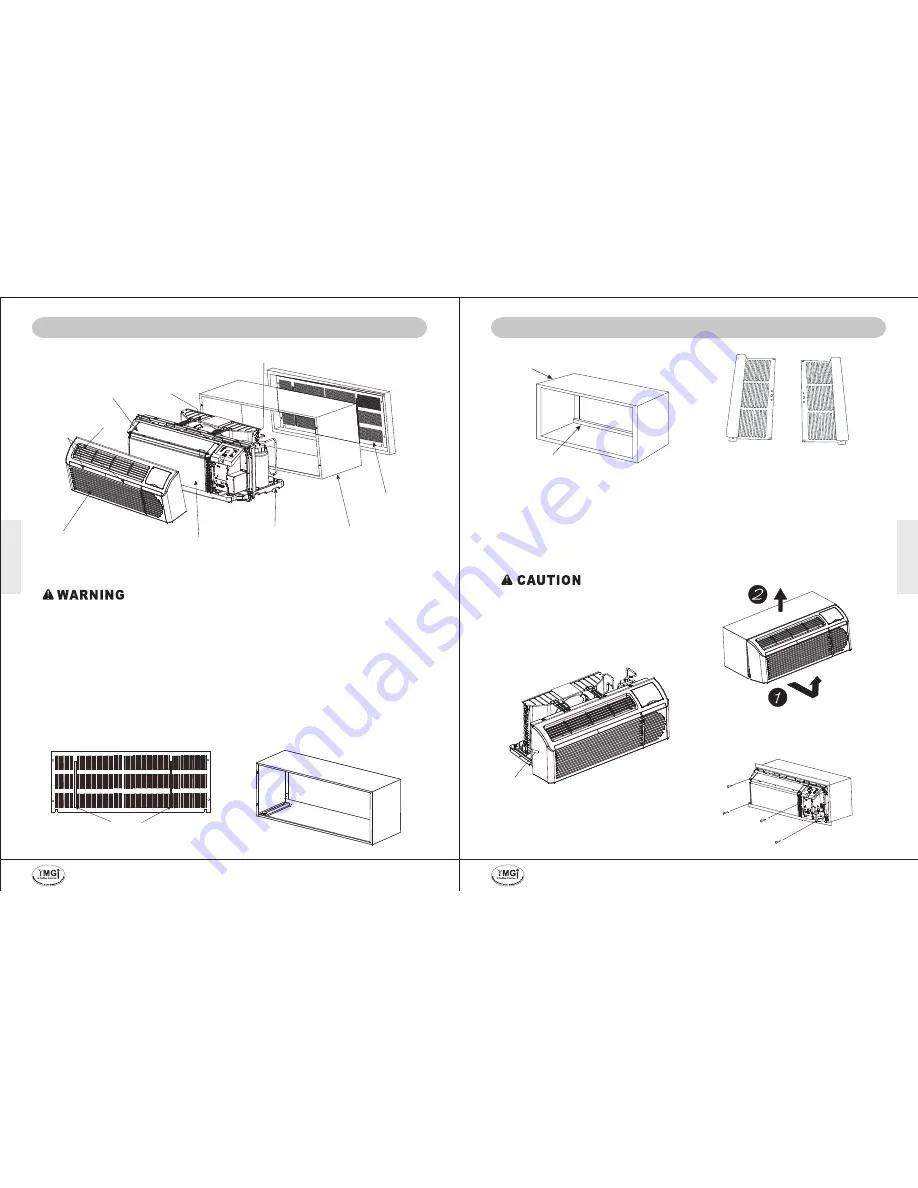

Accessory Baffle Kit

Note:

contact your units supplier to get the kit and

it may be different from the shape showed above.

SLEEVE

BOTTOM SEAL

1) Carefully remove shipping tape from the front panel and vent door.

2) Remove shipping screw from the vent door, if present.

3) Remove front panel.

4) Lift unit level and slide unit into wall sleeve until foam seal rests firmly against front of wall sleeve.

5) Secure with four screws (supplied) through the unit flange holes.

6) Reinstall front panel.

INSTALL UNIT INTO WALL SLEEVE

UNIT DAMAGE HAZARD

* Failure to follow this caution may result in

equipment damage or improper operation.

* Failure to remove shipping tape and screw will

prevent fresh air vent door from opening and may

result in damage to vent door cable.

Shipping Tape Location

Shipping

tape

Pull out at the bottom to release it from the tabs (1).

Then lift up (2).

Removing Front Panel

Securing Unit

INSTALLATION

RETRO FIT SLEEVE PREPARATION

IMPORTANT: Inspect wall sleeve thoroughly prior to installation. Manufacturer does not assume responsibility

for costs or damages due to defects in sleeve or for improper installation.

ELECTRIC SHOCK HAZARD

* Failure to follow this warning could result in personal injury or death.

* Disconnect all power to unit to avoid possible electrical shock during installation.

Remove any existing foam baffles that are installed on competitive outdoor grille, if present.

GE Sleeves Only

GE Meta l Wall Sleeve - GE metal sleeve is interchangeable with YMGI wall sleeve.

GE Plastic Sleeve - Remove bottom seal from plastic sleeve.

This application has become more common due to pre - manufactured windows with built--in grilles or

renovations where a YMGI or Carrier sleeve is used with an existing non - YMGI grille.

Use of a YMGI or Carrier wall sleeve with a non - YMGI grille requires installation of an Accessory Baffle Kit,

which ensures a good seal between the unit and exterior grille to prevent air reticulation. Air reticulation

is a large contributor to performance loss and premature damage to major components.

INSTALLATION OF A YMGI OR CARRIER WALL SLEEVE USING A NON-YMGI GRILLE

Notes: YMGI

stamped grille is interchangeable with CARRIER'S.

BAFFLES

Remove Existing Outdoor Grille Baffles on

Competitive Grille

GE Metal Sleeve

FRONT PANEL

INDOOR COIL

BASEMAN

ACCESSORY

WALL SLEEVE

ACCESSORY

OUTDOOR

GRILLE

INDOOR-AIR

INLET

FILTERS

DISCHARGE

GRILLE

WIRE SCREEN

OUTDOOR

ORIFICE

COIL TUBE SHEETS

YMGI, Engineered Comfort Products for A Sustainable and Efficient Green World !

YMGI, Engineered Comfort Products for A Sustainable and Efficient Green World !